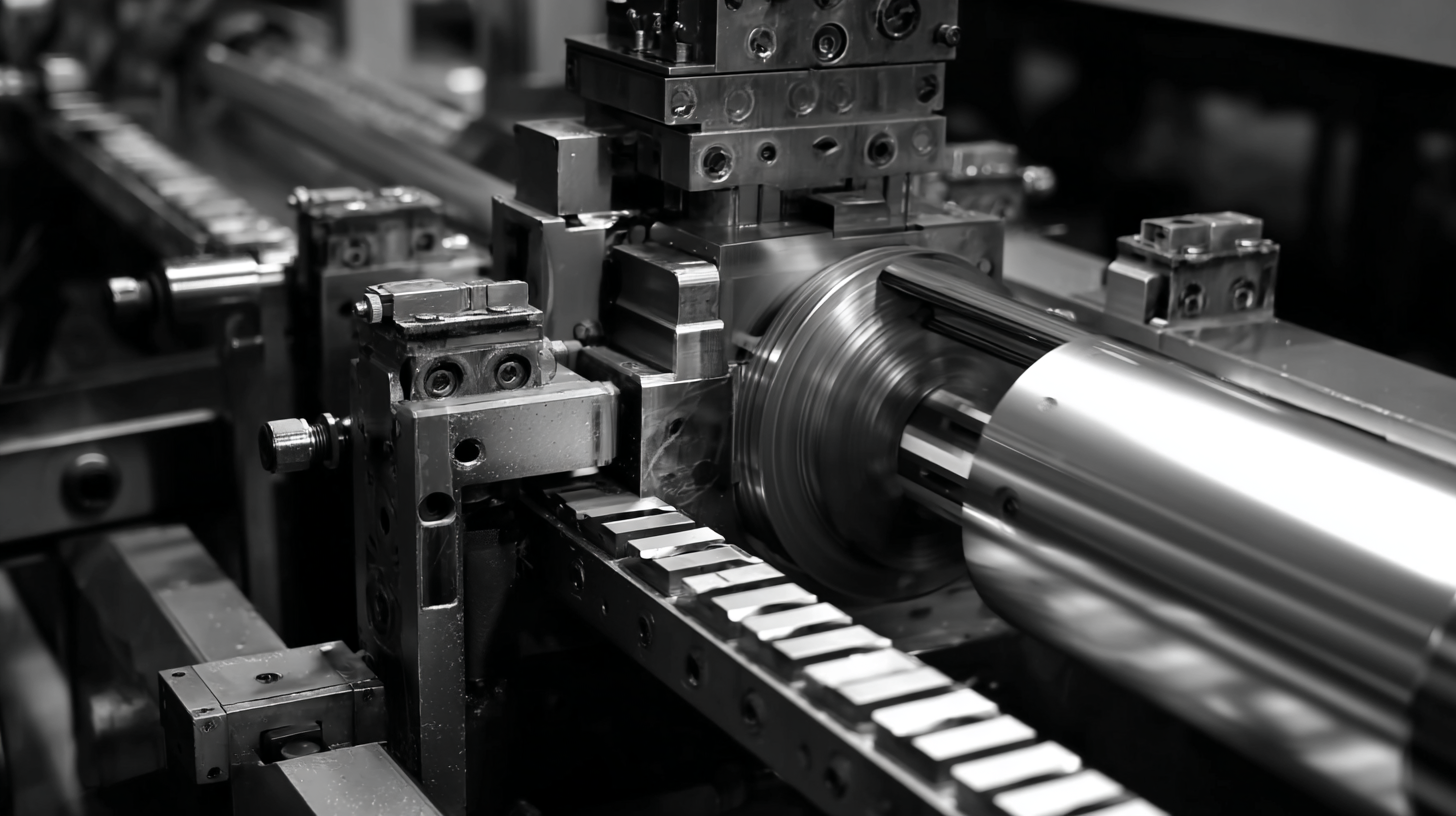

In a rapidly evolving industrial landscape, the quest for efficiency and precision has never been more critical. As manufacturers worldwide strive to align with the ambitious Industry 2025 trends, the metal cut to length line emerges as a pivotal asset in the modernization of production processes. This innovative technology not only enhances operational efficiency but also ensures consistent product quality, a hallmark of globally trusted Chinese manufacturing. By leveraging the capabilities of advanced metal cut to length lines, businesses can optimize their workflows, minimize waste, and meet the ever-growing demands of a competitive market. As we unlock the future of manufacturing, the integration of these cutting-edge solutions will be essential in driving both sustainability and profitability, reinforcing the importance of mastering the art of precision cutting in an era of rapid change.

The metal processing industry is on the cusp of transformation as we approach 2025, driven by technological advancements and evolving market demands. According to a recent report by the International Metalworking Federation, the global metal fabrication market is projected to reach approximately $300 billion by 2025, with a compound annual growth rate (CAGR) of 7.5%. This growth is largely attributed to the integration of automation and smart technologies, which are reshaping traditional processing methods and enhancing efficiency.

A critical trend is the increasing adoption of Industry 4.0 principles, which facilitate real-time data analysis and predictive maintenance in metal cutting operations. Implementing these technologies can lead to a reduction in downtime by up to 20%, according to a study from the Manufacturing Institute. Furthermore, sustainability is becoming paramount, with over 60% of surveyed metal manufacturers indicating plans to invest in eco-friendly practices by 2025. This shift not only aligns with global environmental initiatives but also meets the rising demand for sustainable products within the construction and automotive sectors.

As companies prepare for these changes, the best cut to length lines are adapting to align with these industry trends. By integrating advanced analytics and sustainable practices into their operations, manufacturers can enhance precision, reduce waste, and ensure they are prepared for the rapidly changing landscape of metal processing.

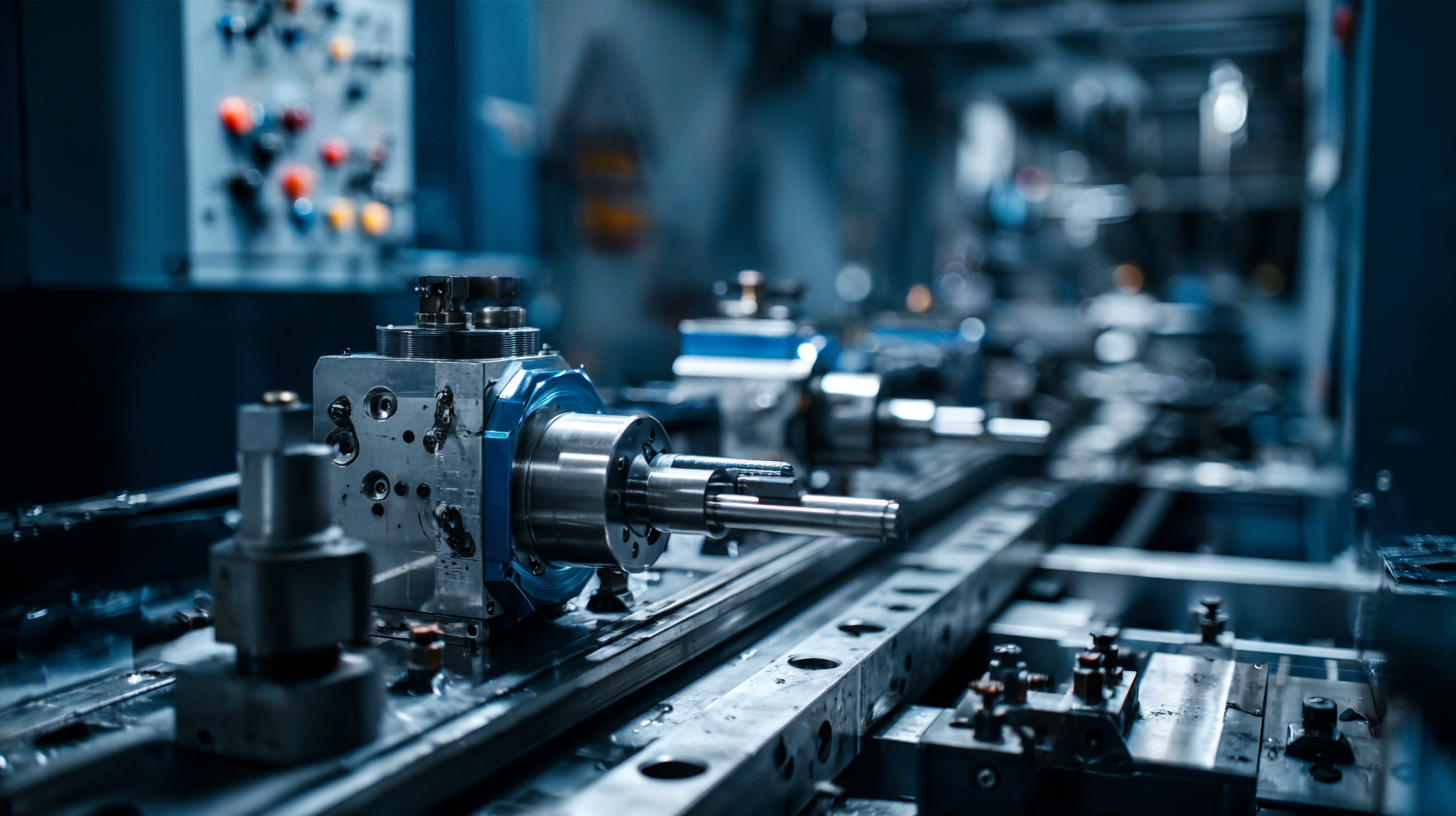

In today's rapidly advancing manufacturing landscape, the integration of innovative technologies into cut to length lines is essential for aligning with Industry 2025 trends. These advancements not only enhance operational efficiency but also significantly reduce production times and costs. By utilizing cutting-edge automation and data analytics, manufacturers can streamline their processes, ensuring precision and consistency in metal cutting applications. This innovative approach mirrors developments in other sectors, showcasing a broad trend towards efficiency and productivity across industries.

The intersection of technology and manufacturing is vividly illustrated by recent strides in various fields, from transportation innovations to advanced energy solutions. Automation and computer vision systems, for instance, have transformed how industries monitor performance and optimize resources. By adopting similar technologies in cut to length lines, manufacturers can achieve unparalleled insights into their workflows, enabling real-time adjustments and improved output quality. These enhancements not only boost operational performance but also contribute to sustainability goals, reflecting a comprehensive understanding of the industry's future landscape.

As industries strive towards the goals set for 2025, the focus on sustainability practices has never been more critical. The best metal cut to length lines are at the forefront of this transformation, employing innovative technologies that reduce waste and improve resource utilization. By integrating lean manufacturing principles, these operations not only minimize excess material but also enhance overall efficiency. This shift not only meets regulatory demands but also appeals to consumers who are increasingly prioritizing eco-friendly practices.

Moreover, sustainable practices in metal processing are increasingly aligned with circular economy principles. By focusing on recycling scrap metal and repurposing materials, companies can significantly reduce their carbon footprint. Advanced cutting technologies are enabling businesses to optimize their processes, ensuring that every piece of metal is utilized effectively. This approach not only contributes to the environment but also strengthens the bottom line, demonstrating that sustainability and profitability can go hand in hand. As the industry moves closer to 2025, those who embrace these practices will be well-positioned to lead the market.

As the manufacturing landscape evolves towards greater customization and flexibility, the demand for advanced metal cutting solutions becomes increasingly urgent. Companies are seeking to optimize their production lines to respond swiftly to market changes and customer preferences. This is where cutting-edge metal cut-to-length systems play a vital role, enabling manufacturers to tailor their offerings with precision and efficiency. By utilizing automated processes, these systems can adapt to varying production needs, facilitating rapid adjustments in both product type and quantity.

The integration of flexible manufacturing systems (FMS) further enhances this capability. An FMS allows manufacturers to seamlessly switch between different tools and techniques, improving workflow and minimizing downtime. This adaptability not only meets the growing demand for personalized products but also improves overall operational efficiency. As the machinery and industrial automation market is projected to grow significantly, embracing these innovative technologies positions companies at the forefront of manufacturing excellence, ensuring they are well-equipped to meet the challenges of Industry 2025 trends.

In today's competitive manufacturing landscape, strategic partnerships are crucial for companies aiming to stay ahead of Industry 2025 trends. A recent report from Deloitte highlights that businesses that engage in collaborative relationships can improve their innovation capabilities by up to 30%. This is particularly relevant for manufacturers of metal cut to length lines, where the integration of advanced technologies and diverse expertise can significantly enhance operational efficiency and product quality.

By forming alliances with technology providers, metal manufacturers can leverage cutting-edge solutions such as AI-driven automation and predictive maintenance tools. According to a survey by McKinsey, 72% of industrial companies believe that partnerships will be key to achieving digital transformation initiatives. Such collaborations not only facilitate knowledge sharing but also allow firms to adapt more swiftly to market demands and reduce time-to-market for new products. As the industry edges closer to smart manufacturing, aligning with the right partners becomes imperative for unlocking future potential and sustaining a competitive advantage.