Dear Customers:

We are very honored to announce that BRUTE STEEL SLITTER will participate in the International Industrial Week Indonesia, which will be held at JExpo Kemayoran from June 4 to June 7, 2025. Booth: C3P206. BRUTE STEEL SLITTER looks forward to friendly exchanges and cooperation with all parties at the exhibition!

BRUTE STEEL SLITTER is a manufacturer of automatic metal slitting machines and high speed cut to length lines with more than two decades of experience. During this time, BRUTE STEEL SLITTER has established good cooperative relations with many countries such as Indonesia, the Philippines, the UAE, Saudi Arabia, Argentina, India, etc. BRUTE STEEL SLITTER goal has always been to provide customers with efficient and high-quality mechanical solutions to help them succeed in the competitive market.

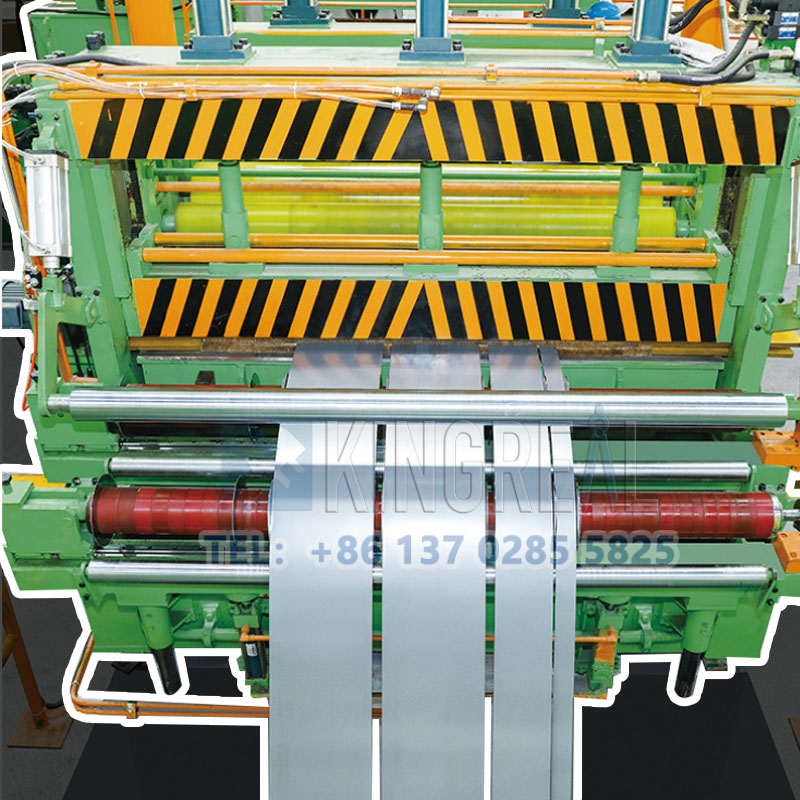

In the field of mechanical manufacturing, metal slitting lines are a major feature product of BRUTE STEEL SLITTER. BRUTE STEEL SLITTER provides customers with various types of metal coil slitting machines to meet different materials and production needs.

● Metal Coil Slitting Machines for Different Materials

BRUTE STEEL SLITTER is able to provide professional metal coil slitting line solutions for different materials. For example, BRUTE STEEL SLITTER has customized several fully automatic metal slitting machines for customers in Russia, Canada and Egypt. These machines can handle a variety of materials such as steel coils, stainless steel coils, and aluminum coils. The metal coil slitting machines provided by BRUTE STEEL SLITTER include:

Steel Coil Slitting Line: Designed specifically for steel coils, it can efficiently handle steel coils of different thicknesses and widths.

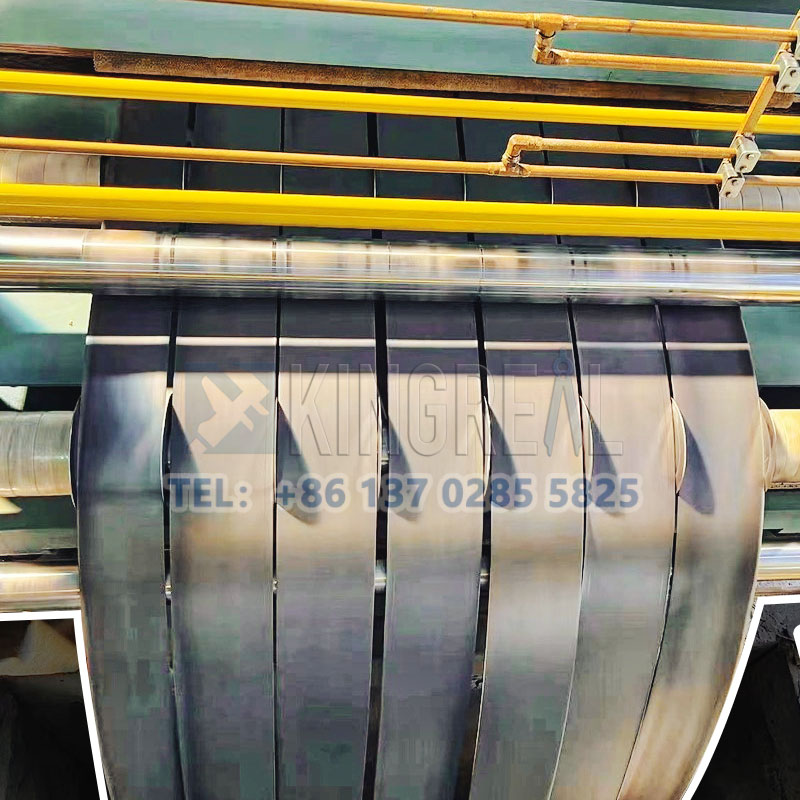

Stainless Steel Slitting Machine: It meets the special requirements of stainless steel and ensures that there are no scratches and defects.

Aluminum Steel Coil Slitting Machine: It is lightweight and efficient, suitable for slitting aluminum.

Cold Rolled Slitting Machine: It is suitable for cold-rolled products to ensure a flat surface after cutting.

Hot Rolled Slitting Machine: It is designed for hot-rolled coils and can handle high temperature environments.

Galvanized Steel Slitting Machine: It is specially designed for galvanized steel to avoid damaging the coating during the cutting process.

|

|

|

Metal Coil Slitting Lines for different materials have significant differences in parameters and manufacturing requirements. For example, the hardness and thickness of the steel will affect the design of the tool, while stainless steel requires higher cutting accuracy and surface treatment. Therefore, BRUTE STEEL SLITTER will adjust the design according to the specific needs of customers to ensure that each machine can perfectly adapt to their production environment.

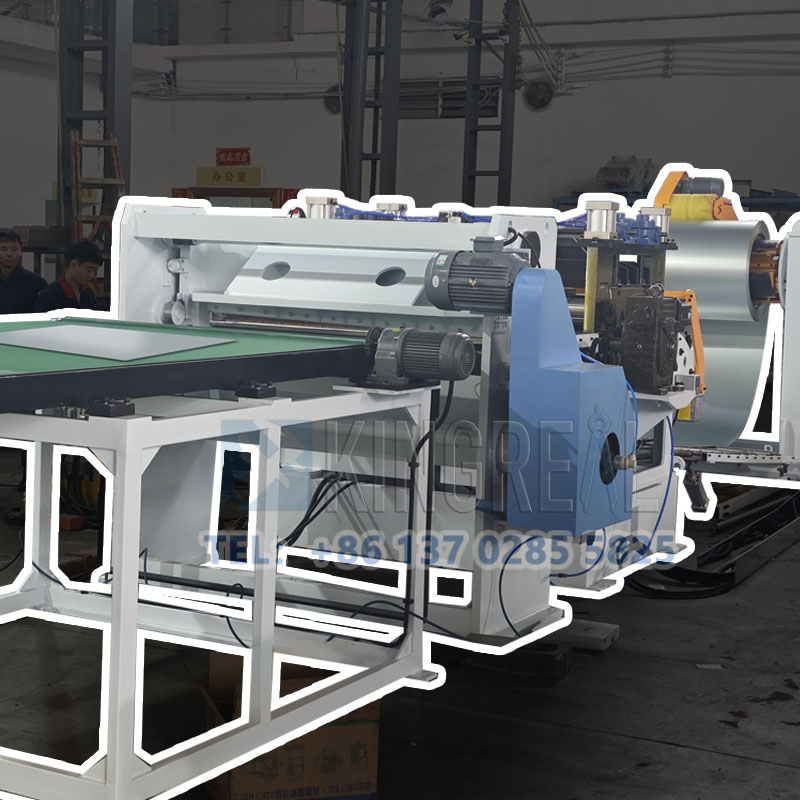

● Customized Metal Coil Slitting Machines

According to the actual needs of Turkish and Italian customers, BRUTE STEEL SLITTER also designed customized metal coil slitting lines, such as Dual Slitter Head Slitting Machine and Belt Tension Coil Slitting Machine. These machines greatly improve the slitting accuracy and can be flexibly adjusted according to different production line configurations and material characteristics, greatly improving production efficiency.

|

|

● Metal Coil Slitting Lines for Materials of Different Thicknesses

BRUTE STEEL SLITTER provides a variety of Copper Strip Coil Slitting Lines with different parameters according to the thickness of the customer's processing materials. BRUTE STEEL SLITTER Heavy Duty Steel Slitting Machine can handle metal coils with a thickness of 6-16mm, which is widely praised by customers in the United States and Brazil. The Light Gauge Slitting Machine is suitable for metal coils with a thickness of 0.2-3mm, suitable for customers with lighter needs. And the medium gauge slitting machine is suitable for metal coils with a thickness of 3-6mm. This flexible design allows customers to choose the most suitable equipment according to actual production needs.

|

|

|

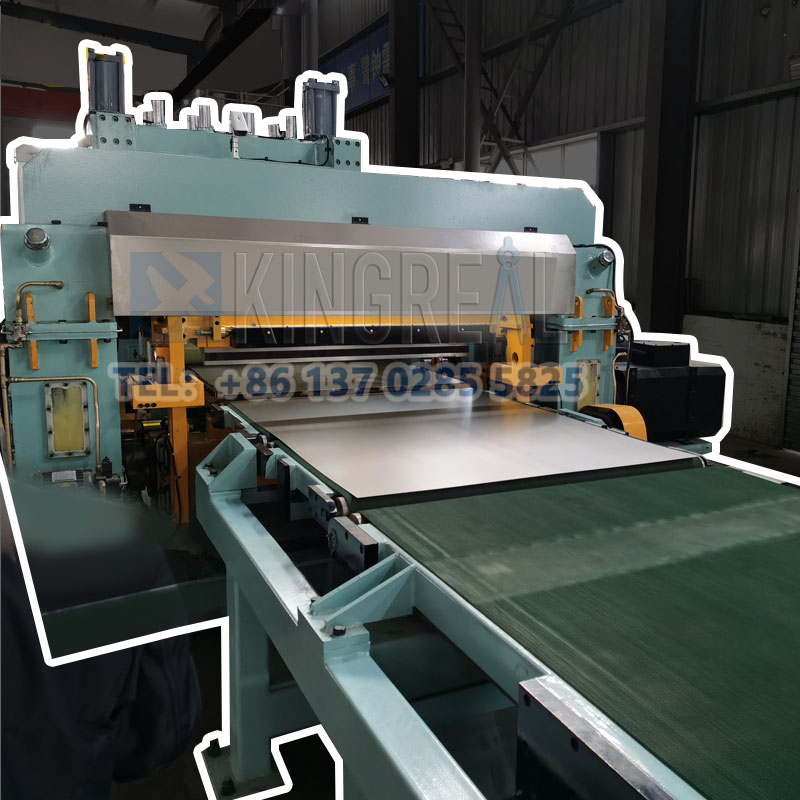

In addition to metal coil slitting machines, BRUTE STEEL SLITTER also has extensive experience in the manufacturing of high speed cut to length lines. BRUTE STEEL SLITTER provides a variety of Steel Cut to Length Machine solutions based on different shearing methods and material thicknesses.

● Stainless Steel Cut To Length Machines with different shearing methods

BRUTE STEEL SLITTER has successfully sold Fly Shearing Cut To Length Machine and Rotary Shearing Cut To Length Machine to Indonesia, India, Pakistan and Thailand. These two Metal Cut To Length Lines are one of BRUTE STEEL SLITTER best-selling products. Their production speed can reach 80M/MIN, and there is no need to stop during the shearing process, which greatly improves production efficiency.

|

|

● High Speed Cut To Length Line with different thicknesses

BRUTE STEEL SLITTER provides Stainless Steel Cut To Length Machines including Light Gauge Cut To Length Line, Medium Gauge Cut To Length Line and Heavy Gauge Cut To Length Lines, which have solved many production problems for customers in Mexico and Argentina. Each Metal Cut To Length Lines is designed for materials of different thicknesses, avoiding material waste and mismatched production problems. For example:

Medium Gauge Cut To Length Line: can handle plates with a thickness of 0.3-6MM.

Heavy Gauge Cut To Length Lines: can handle plates with a thickness of 6-20MM.

Light Gauge Cut To Length Line: can handle plates with a thickness of 0.3-3MM.

This diversity allows BRUTE STEEL SLITTER Steel Cut to Length Machines to meet the specific needs of different customers.

|

|

|

● High-efficiency and high-precision High Speed Cut To Length Lines

In order to maximize the production needs of customers in Chile and Pakistan, BRUTE STEEL SLITTER has launched a series of high-efficiency and high-precision Steel Cut to Length Machine. These Stainless Steel Cut To Length Machines can be equipped with components such as double levelers, double stacking tables and laminating devices to improve the speed and quality of the entire shearing process.

Metal Cut To Length Lines with double levelers: In order to ensure the flatness of the plate, the coil needs to be leveled twice, which is suitable for customers with high quality requirements.

Rotary Shearing Cut To Length Machine with double stacking tables: Two stacking tables stack the cut metal plates at the same time, which speeds up the processing speed and reduces labor costs.

Simply Cut To Length Line with laminating device: Before the coil enters the Metal Cut To Length Lines, a layer of protective film is first covered on the surface by the laminating device to avoid scratches on the surface during the shearing process.

|

|

|

BRUTE STEEL SLITTER is looking forward to sharing our expertise and latest technology solutions with you at the upcoming International Industry Week. Whether you are looking for a Silicon Coil Slitting Line or a Stainless Steel Cut To Length Machine, BRUTE STEEL SLITTER will be your trusted partner. BRUTE STEEL SLITTER sincerely invites you to visit our booth to learn more about our products and services. Let's explore future cooperation opportunities and take your business to the next level.

Looking forward to seeing you at the exhibition!

Best wishes,

BRUTE STEEL SLITTER team