Welcome to BRUTE STEEL SLITTER "Coil Cut To Length Machine"product section! This section is dedicated to introducing our advanced coil cut to length machines, which play a crucial role in the field of coil processing.

BRUTE STEEL SLITTER Cut To Length Machine utilize cutting-edge technology and precision craftsmanship, designed to meet the efficient length requirements of various industries. Whether you are in metal processing, construction materials, or other fields, BRUTE "Coil Cut To Length Machine" provides reliable and precise cutting solutions.

Through this section, you will gain in-depth insights into the features of Cut To Length Machine, including advanced automation control systems, adjustable cutting dimensions, high-speed production capabilities, and more. We are committed to providing customers with integrated solutions, improving production efficiency, reducing costs, and ensuring Cut To Length Machine quality.

(1) Metal sheets of different thicknesses:

Different industries of customers have different requirements for the thickness of the metal sheets to be processed. BRUTE STEEL SLITTER engineers have launched three sheet metal cut to length machines for different plate thicknesses:

|

|

|

|

Medium Plate Cut To Length Line Thickness : 0.3-6MM |

Heavy Duty Cut ToLength Machine Thickness: 6-20MM |

Thickness : 0.3-3MM |

(2) Various shearing methods:

BRUTE STEEL SLITTER can provide customers with steel coil cutting machines with different shearing methods: fly shearing cut to length line, swing shearing cut to length machine and fixed shearing cut to length machine.

|

|

|

|

Fly Shearing Cut To Length Line Speed : 80M/MIN |

Swing Shearing Cut To Length Line Speed : 80M/MIN |

Fixed Shearing Cut To Length Line Speed : 50M/MIN |

(3) Various metal materials:

BRUTE STEEL SLITTER's cut to length production line can shear a variety of materials, including but not limited to steel, stainless steel, aluminum, hr, cr, etc.

|

|

|

(4) Customized machines:

BRUTE STEEL SLITTER will provide customized coil cut to length machine manufacturing solutions for customers' specific production needs.

Stainless steel cut to length line with dual stacker: In order to maximize customer production efficiency, BRUTE STEEL SLITTER can equip customers' stainless steel cut to length machines with two stackers.

Steel cut to length machine with lamination: Before cutting, a layer of film is applied to the sheet to protect the surface of the metal sheet.

High speed hr cut to length line: Composed of fully automated components to improve customer production efficiency.

|

|

|

Whether you are an engineer, manufacturer, or professional in the coil processing industry, BRUTE believe that in the "Coil Cut To Length Machine" product section, you will find innovative solutions that best suit your needs. Thank you for visiting, and we look forward to providing you with excellent coil cutting solutions!

BRUTE STEEL SLITTER has reached cooperation with customers in many countries and regions, such as Egypt, Turkey, India, Pakistan, Saudi Arabia and Russia. And it has been well received by customers. Welcome to visit our factory.

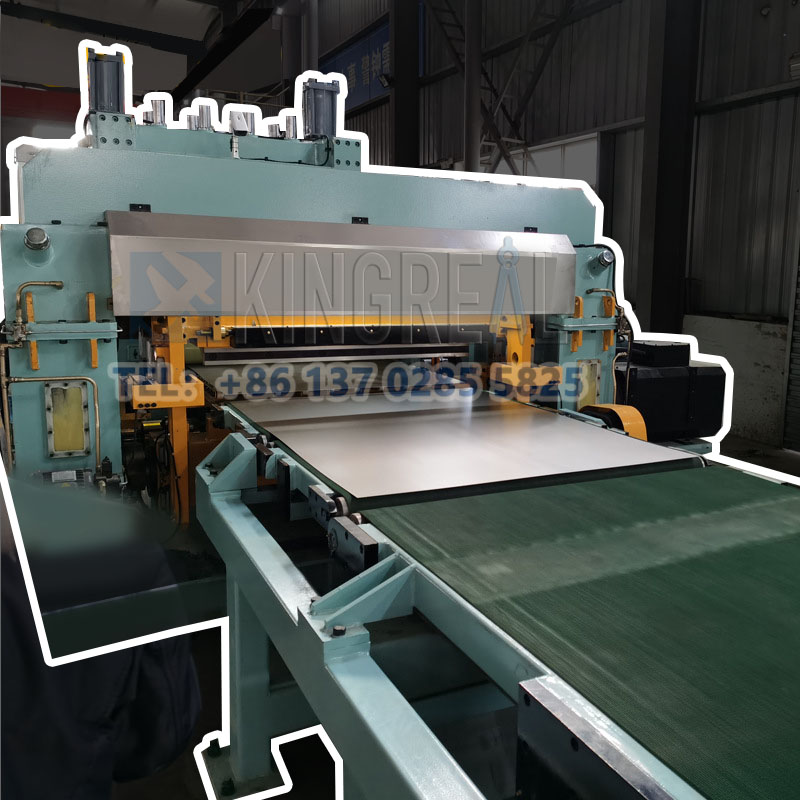

Precision shearing. BRUTE STEEL SLITTER sheet metal cut to length machine can accurately cut metal sheets. It composed of precision components can ensure the consistency of shearing and ensure that the length required by customers is cut.

High efficiency. Just adjust the parameters, and the fully automatic steel coil cut to length line can automatically run to process a large number of metal coils for shearing. The whole process does not require too much human involvement, which improves production efficiency.

Versatility. BRUTE STEEL SLITTER metal cut to length machine has a wide range of uses and can adapt to various metal raw materials, including stainless steel, steel, cold rolling, hot rolling, etc. And it can be adjusted and customized to adapt to different thicknesses, widths and lengths, so as to achieve production flexibility and meet various requirements.

Cost savings. BRUTE STEEL SLITTER's precision cut to length equipment can reduce material waste, and the fully automatic multi blanking cut to length line can reduce labor costs.

CR Coil Cut To Length Line - BRUTE SLITTER is designed for precision cut-to-length cutting of cold rolled materials of common thicknesses from 0.3 to 3MM. More than 20 years of production experience can provide diversified production solutions, welcome to contact us!

Cut To Length Machine - Swing Shearing is design for high speed shearing process, which speed up to 80M/Min. Provide whole solution of cut to length line, welcome to contact us!

BRUTE 850MM Cut To Length Line Machine is designed to process rolls up to 850MM in width and is capable of uncoiling, leveling, shearing and stacking. Please contact us for more information.

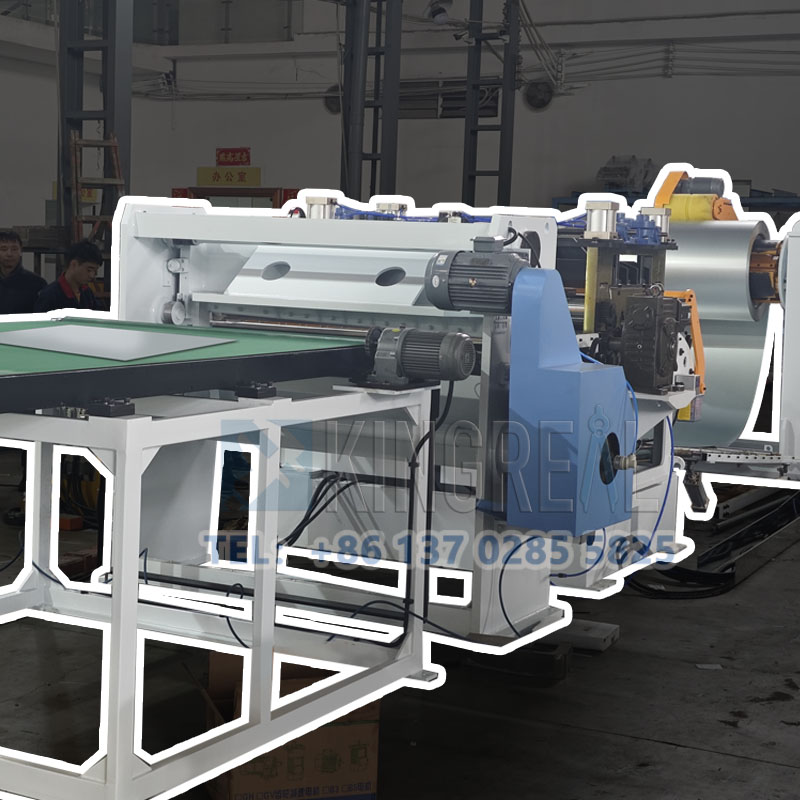

BRUTE Slitter 2024 Auto Metal Sheet Decoiler Leveler Shearing Machine is specially designed for uncoiling, leveling and cutting off coiled materials, and is suitable for processing small and medium-sized metal sheets. It has been successfully sold to countries such as Russia and India

The production range of BRUTE Steel Coil Cutting Machine covers a wide range of thicknesses from 0.3 to 12mm and widths up to 2000mm. BRUTE has rich experience in project production and can provide you with professional program design for Steel Coil Cutting Machine For Narrow Strip.

BRUTE has designed 12-16MM HR Cut To Length Line specifically for sheet metal thicknesses up to 12-16MM, which requires a high level of decoiler, leveling and shearing equipment. If you are interested, please feel free to contact us.

BRUTE STEEL SLITTER has a highly qualified professional technical team and a 24-hour online customer service team. They not only have a deep reserve of professional knowledge, but also have rich practical experience, and can answer customers' various questions about high speed cut to length lines in a timely and effective manner.

BRUTE STEEL SLITTER is committed to providing customers with a comprehensive one-stop solution, covering all aspects of cut to length production line design, production, installation, maintenance and after-sales service. BRUTE STEEL SLITTER's goal is to significantly improve efficiency and reduce customers' time and cost investment by integrating resources and optimizing processes, so that customers have no worries throughout the project.

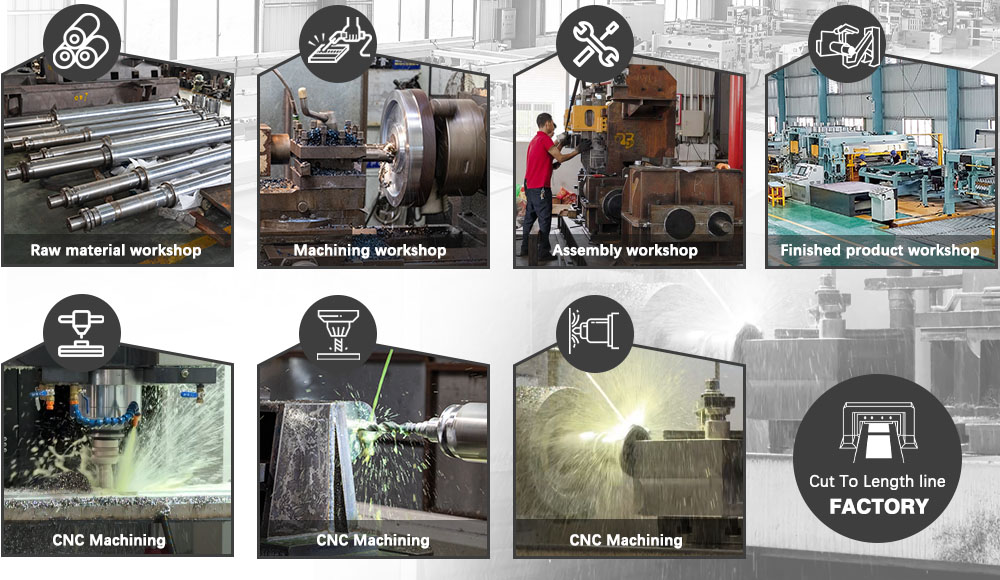

In the selection of raw materials, BRUTE STEEL SLITTER follows a strict evaluation process to ensure that every material meets high standards. In the manufacturing process of the multi blanking cut to length line, even the smallest component is required to match the other parts of the equipment perfectly. This attention to detail has made BRUTE STEEL SLITTER's metal cut to length machine win unanimous praise from customers in the market.

BRUTE STEEL SLITTER welcomes customers from all over the world to visit the BRUTE STEEL SLITTER factory. BRUTE STEEL SLITTER staff will accompany customers throughout the whole process to visit the cut to length machine manufacturing workshop, coil cut to length line machine assembly workshop, test machine workshop, etc. And invite customers to operate the sheet metal cut to length machine in person, so that customers can have a deeper understanding of the BRUTE STEEL SLITTER stainless steel cut to length machine.

BRUTE STEEL SLITTER actively communicates with customers online or offline. Whether it is pre-sales communication of machine solutions, in-sales communication of machine manufacturing conditions or after-sales machine operation training, BRUTE STEEL SLITTER will communicate with customers in the first meeting.

BRUTE STEEL SLITTER can send professional engineers to the customer's factory for offline installation of the steel cut to length machine. BRUTE STEEL SLITTER engineers will assemble the equipment in place according to the actual space of the customer's factory. And necessary adjustments will be made to the high speed cut to length machine to ensure smooth operation of the equipment. Workers will also be trained on the use and maintenance of the equipment.