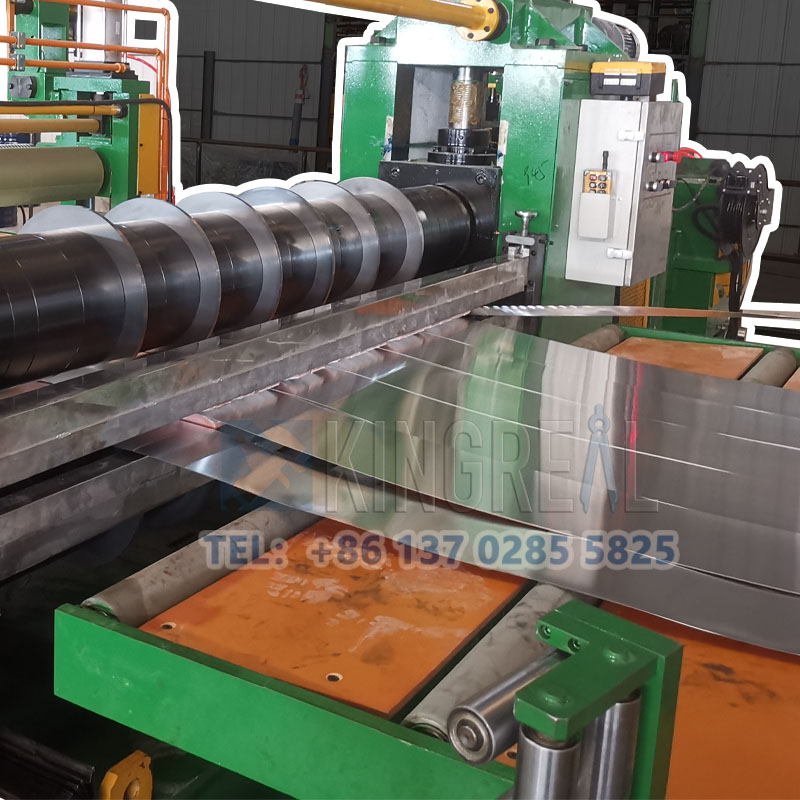

Coil Slitting Machine is a kind of high-efficiency equipment specially designed for cutting wide metal coils longitudinally into a number of narrow strips, which can be used to process steel, aluminum, stainless steel, copper and other metals for longitudinal shearing, and is suitable for coils with different thicknesses according to customer's production needs, for slitting and final winding.

BRUTE STEEL SLITTER popular longitudinal cut to length line and steel slitting machine Products include double slitter head coil slitting machine, full auto metal slitting machine, metal sheet slitting machine, stainless steel slitting machine, coil slitting machine with belt tension, heavy gauge coil slitting machine and so on.

● Metal coil slitter machines for different coil thicknesses

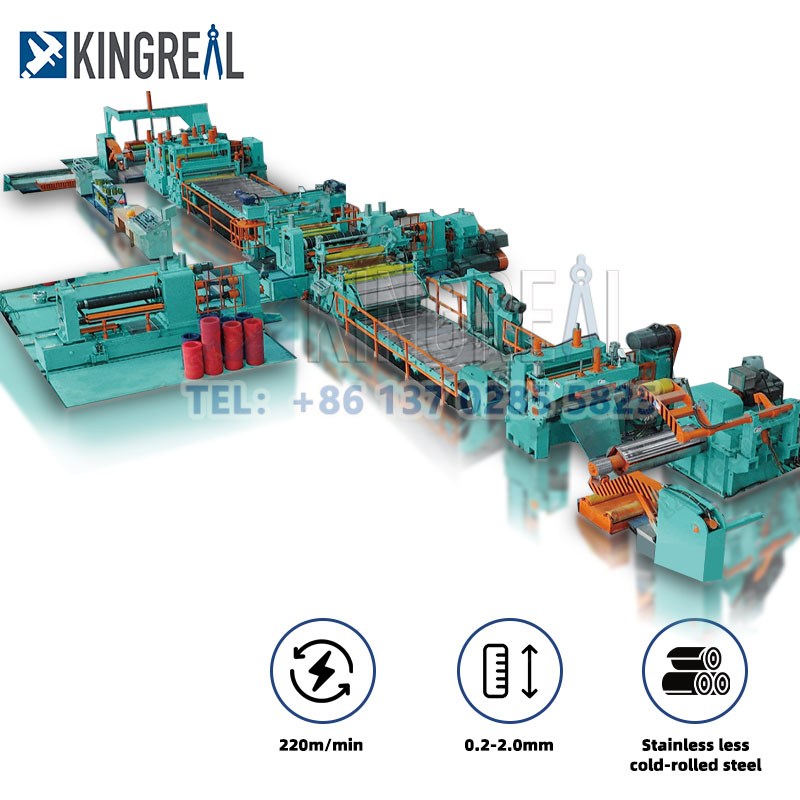

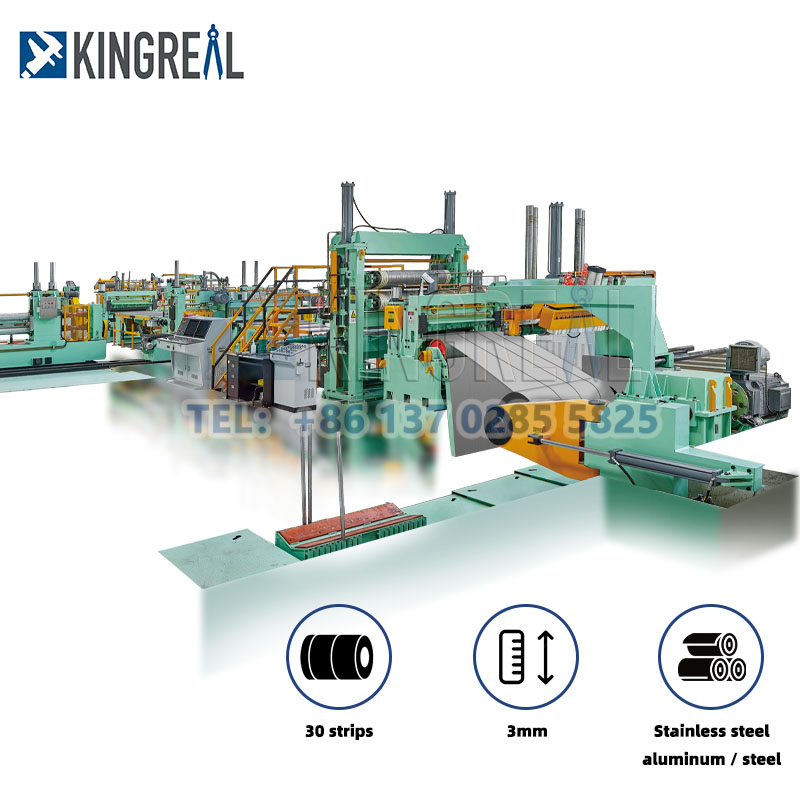

The market demand for high quality coil slitting machines is gradually increasing, and different application fields require different metal coil thicknesses. BRUTE STEEL SLITTER engineers have keenly grasped this point and designed three sheet metal slitting machines for different coil thicknesses.

Light gauge slitting machine. It can handle metal sheets with a thickness of 0.2-3mm.

Medium gauge slitting machine. It can handle metal sheets with a thickness of 3-6mm.

Heavy gauge slitting machine. It can handle metal sheets with a thickness of 6-16mm.

● Automatic coil slitting machines for different coil materials

For common metal materials on the market, BRUTE STEEL SLITTER has corresponding fully auto slitting lines to handle them. BRUTE STEEL SLITTER has launched a series of metal slitting machines such as aluminum coil slitting machines, silicon steel slitting machines, hot roller slitting machines to meet the needs of different customers.

|

|

|

● Customized metal coil slitter machines

BRUTE STEEL SLITTER will provide customized high speed coil slitting machine manufacturing solutions based on customer drawings and specific production needs to ensure that the sheet metal slitter can be fully applicable to the customer's factory when it is put into use.

Dual slitter head coil slitting machine. The double-knife seat design can realize the slitting of coils of different sizes on the same production line. By replacing the knife seat, the production efficiency is greatly improved, which has been highly praised by customers.

Belt tension steel slitting machine. The belt tensioning device is a combination design of belt tensioner and felt pressing interchangeable. The steel belt is squeezed by the upper and lower belts or felt, generating friction and providing tension for coiling. The belt tension device is suitable for customers who have high requirements for scratch-free surface of metal coils, and can produce finished products with higher precision.

Automatic coil slitting line. It's composed of fully automatic components, and the entire slitting process does not require manpower. It increases production speed and saves labor costs and time.

|

|

|

Mechanical Structure Design

1.Unwinding mechanism for coil slitting line: The coil slitting line unwinding mechanism is used to unwind and support the coil, usually equipped with a rise and fall shaft, a brake device and an automatic centering device to ensure smooth unwinding and centering of the coil.

2.Slitting mechanism for metal coil slitting line: The coil slitting machine shearing mechanism is the core part of the slitting machine, which adopts high-precision knife shaft and shearing tool for cutting. The knife shaft is supported by precision bearings to ensure smooth operation and precise cutting.

3.Guiding and Tension Control System for steel coil slitting machine: The metal slitting machine guiding device ensures the stable running of the strip during the shearing process, and the tension control system maintains the proper tension of the strip by means of tension sensors and feedback control.

Power Transmission Design For High Precision Coil Slitting Line

1. Servo motor and frequency converter: Servo motor and frequency converter are used to drive the knife shaft and rewinding shaft to ensure precise control of cutting speed and tension. The servo system is characterized by fast response and high precision control.

2. Coupling and reducer: The power is transferred to the knife shaft and winding shaft through the coupling and reducer to ensure the smoothness and reliability of the transmission system.

Italy 850mm Automatic Coil Slitting Machine

|

After communicating online for a while, BRUTE STEEL SLITTER warmly invited Italian customers to visit the BRUTE STEEL SLITTER factory to visit the sheet metal slitting machine and communicated offline.

During the discussion, the engineer asked about the thickness and width of the metal coils that the customer usually uses, and learned about the customer's production scale, the metal material used, and the application field after slitting.

After detailed demand analysis and discussion, BRUTE STEEL SLITTER's engineers integrated all aspects of the customer's needs and finally designed a fully auto coil slitting line for the customer that is specially designed to handle 0.3-2mm thick metal coils, 850mm coil width, and galvanized sheet as the metal raw material. This customized solution not only meets the customer's technical requirements, but also takes into account the improvement of its production efficiency, which has been highly praised by the customer. |

UAE 230m/min High Speed Coil Slitting Machine

|

Due to the expansion of production scale, customers from the United States urgently need more efficient high speed coil slitting line, and found BRUTE STEEL SLITTER on the recommendation of BRUTE STEEL SLITTER's old customers. Ask if a high-speed slitting machine can be made.

After many online communications and offline talks, BRUTE STEEL SLITTER finally designed a customized metal coil slitter machine for American customers with a maximum speed of 230m/min, which can handle galvanized steel, cold-rolled steel, and PPGI metal raw materials. BRUTE STEEL SLITTER's professionalism in metal coil slitter and the meticulousness of the team left a deep impression on American customers. And claimed that BRUTE STEEL SLITTER would be recommended to more peers who have the need to purchase metal coil slitter. |

Saudi Arabia 1650mm Coil Slitting Machine

|

Since Saudi Arabia is in the stage of large-scale industrialization and infrastructure construction, especially under the impetus of the "Vision 2030" plan, the country's investment in industries such as construction, manufacturing and transportation has continued to increase. The demand for metal materials has also risen, especially in the fields of construction, automobiles and home appliances. Wide-width sheet metal slitting machines can efficiently process large-format metal coils to meet the demand for metal materials in these industries.

Saudi Arabian customers hope to purchase advanced sheet metal coil slitters to improve production efficiency and product quality. BRUTE STEEL SLITTER engineers combined the local Saudi Arabia sheet metal slitter parameter requirements and the customer's actual production needs to customize a brass coil slitting machine that can handle a width of up to 1650mm, providing customers with more flexible production options to meet diverse product needs. |

BRUTE MACHINERY is a steel strip slitting machine manufacturer and supplier in China. BRUTE has more than 20 years of experience in the field of slitting machine production, the quality of the produced steel slitting line can be guaranteed, and it can provide complete design, production, delivery and installation servicesVideo About Steel Slitter Line

BRUTE STEEL SLITTER is one of the most professional coil process equipment manufacturer and supplier in China. BRUTE can provide copper coil slitting machine, which can precise slitting the copper coil to the same width. Welcome to ask for a quotation.

High Precision Speed Steel Coil Slitting Machine is one of BRUTE’s feature product. As one of the professional coil manufacturers in China, BRUTE is committed to providing customers with high quality production equipment to help can improve production efficiency. We are looking forward to reaching long-term cooperation with our customers all over the world.

BRUTE MACHINERY is a professional manufacturer and supplier of coil processing equipment in China, able to provide high quality automatic medium plate slitting machine. Our slitting machines are used for slitting a wide variety of materials with many user-friendly features incorporated using cutting-edge technology. Welcome to contact us.

BRUTE is a professional manufacturer in the field of coil slitting machines in China, able to provide high quality narrow strip coil slitting machine.With more than 20 years of production experience, we can design and produce slitting machines according to the different needs of customers. Looking forward to reaching stable cooperation with customers from all over the world.

BRUTE is a professional thin plate sheet slitting machine manufacturer and supplier in China. BRUTE has been focusing on the field of slitting machines for more than 20 years, has rich production experience, has a professional technical team, and can design different coil slitting machines for customers. Welcome to contact us

Your Premier Coil Slitting Machine Manufacturer

BRUTE STEEL SLITTER is a professional manufacturer and supplier of metal coil slitting machine equipment in China, which is able to customize the design of steel slitting machine drawings and manufacturing coil slitting machine solutions according to the needs of customers, and is committed to providing customers with the optimal solution to establish a long-term and stable relationship.

BRUTE STEEL SLITTER is good at customized solutions for high precision coil slitting lines. BRUTE STEEL SLITTER's engineers will provide customers with an automatic coil slitting machine manufacturing solution that is exclusive to the customer based on the customer's drawings and after full communication with the customer to obtain the customer's actual production needs. Customized high quality coil slitting machine manufacturing solutions ensure that the equipment finally delivered can fully match the customer's requirements.

BRUTE STEEL SLITTER has a 24-hour online customer service team, who are familiar with the operation and common problems of various metal coil slitter machines after a long period of professional training. This enables BRUTE STEEL SLITTER's customer service to quickly and accurately answer customers' questions and solve the various challenges they encounter during use. No matter which time zone the customer is in, BRUTE STEEL SLITTER's quick response can make them feel at ease and ensure that their production line will not be affected by equipment problems.

Quality is the core principle that BRUTE STEEL SLITTER always adheres to. In the manufacturing process of the aluminium slitting machine, BRUTE STEEL SLITTER strictly controls every link. From the selection of raw materials to the manufacture of each component, to the final assembly of the whole machine, there is a strict process to ensure that every step meets high standards of quality requirements. In addition, BRUTE STEEL SLITTER has a professional regulatory department that is responsible for supervising the manufacturing process and ensuring that all steel coil slitting machines are strictly tested and inspected before leaving the factory.

With more than 20 years of experience in steel coil slitting machine manufacturing, BRUTE STEEL SLITTER has accumulated rich knowledge and technology in this field. BRUTE STEEL SLITTER has cooperated with customers from Saudi Arabia, Russia, India, Bangladesh, the United Arab Emirates, the United States and other countries, and successfully provided them with efficient ss coil slitting machine solutions. In addition, BRUTE STEEL SLITTER's engineering team has a deep technical background and can develop practical steel coil slitting machine manufacturing solutions according to the needs of different markets.

1. Processing Technology

Precision machining: adopt high-precision machining equipment and processes, such as CNC machine tools, grinding machines, etc., to ensure the machining precision of each component of the metal slitting machine.

2. Quality Control

Strict inspection standards: establish strict quality inspection standards, conduct comprehensive inspection on raw materials, processing and finished products to ensure that each index of the coil slitting equipment meets the design requirements.

3. Installation And Commissioning

Professional installation team: equipment installation is carried out by experienced installation team to ensure the correct installation and trial of the stainless steel coil slitting machine.

System debugging: system debugging of the whole machine, including mechanical parts, transmission parts and control system, to ensure that the performance of the metal slitting line meets the design requirements.