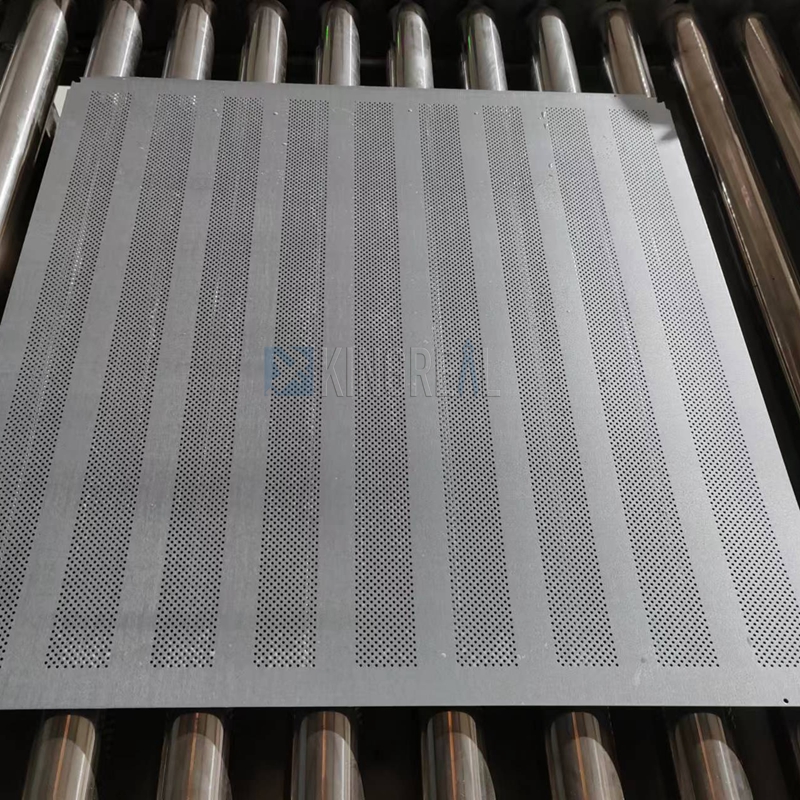

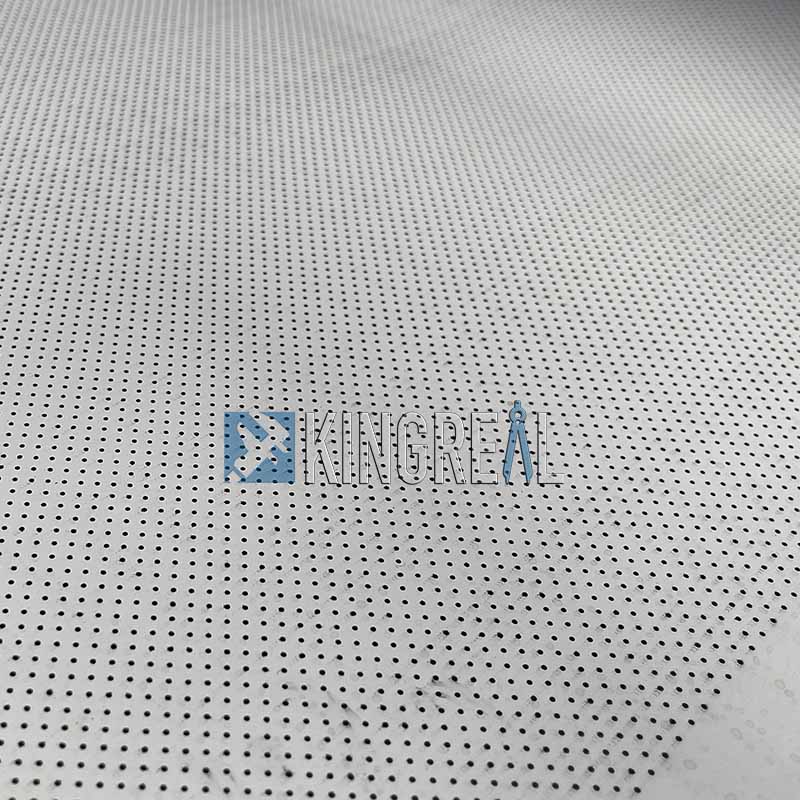

Metal perforated machine is a special equipment for metal sheet processing, mainly used to accurately punch holes in metal materials. It can continuously punch holes in various metal materials, such as steel plates, stainless steel, aluminum plates, etc., and is widely used in construction, automobiles, home appliances, ventilation, filtration, and decoration industries.

|

|

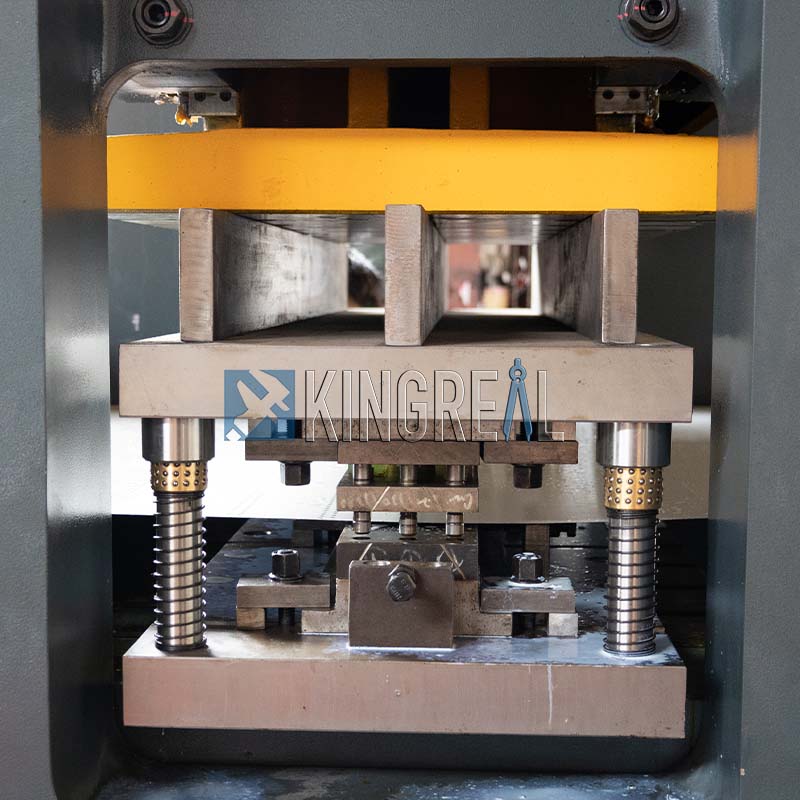

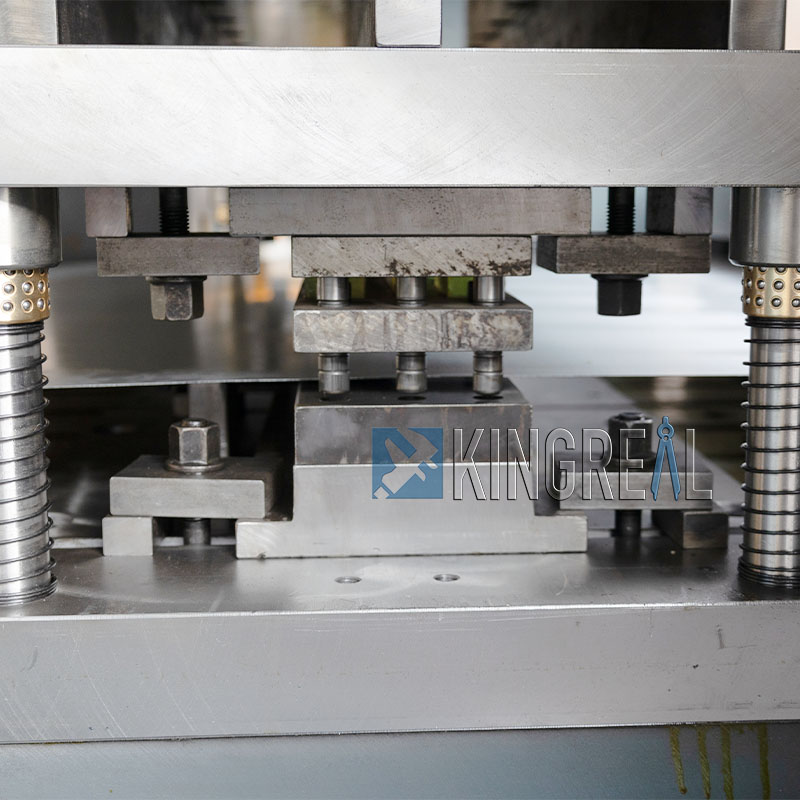

The perforated metal production line usually consists of multiple parts, including decoiler, punching machine, transmission systems, cutting devices, automatic conveying and control systems, etc. Through the automated control system, the perforated metal production line can efficiently and accurately perform large-scale metal sheet punching. The core function of the equipment is to punch the preset hole type and aperture into the metal plate through customized punching dies and high-pressure impact force. The size, shape, arrangement spacing, etc. of these holes can be customized according to needs.

1. Construction and decoration industry

In modern buildings, the application of metal materials is becoming more and more extensive, especially for metal ceilings, curtain walls, partitions and other products. Many architectural designs require metal sheets to have beautiful appearance and reasonable hole distribution. Therefore, perforated metal production lines can help the construction industry efficiently produce metal sheets with special design requirements. In addition, metal decorative materials usually require consistent hole size and good load-bearing capacity and permeability. sheet metal perforation machines can provide high-precision, high-quality hole processing to meet market demand.

2. Automobile Manufacturing Industry

In automobile manufacturing, especially in automobile body, chassis, exhaust system and other parts, the demand for punching of metal sheets is getting higher and higher. Punching is not only used to reduce the weight of the car body, but also to improve ventilation performance, shock absorption and noise reduction. Perforated metal production lines can efficiently and accurately meet these requirements, especially for mass-produced automotive parts, automated punching equipment can provide higher production efficiency and consistency.

|

|

|

3. Home Appliances and Electronics Industry

Metal casings, heat sinks, filters and other parts in home appliances, electronic products and communication equipment often require punching. As consumers' requirements for the appearance and function of home appliances increase, exquisite punching design has become part of the product's appeal. Metal perforated machines can complete mass production at high speed while maintaining high-precision aperture and arrangement to meet the production needs of home appliances and electronics industries.

4. Ventilation and filtration industry

In ventilation ducts, air filters, oil filters and other equipment, the punching of metal plates is an indispensable link. The perforated metal production line can produce holes of different sizes and shapes as needed to ensure the effect of air circulation or liquid filtration. Therefore, with the continuous improvement of environmental protection requirements, punching lines play an important role in the production of ventilation and filtration equipment.

5. Energy industry

In the manufacture of renewable energy equipment such as solar energy and wind energy, the punching of metal materials is also indispensable. Especially in the manufacturing process of solar panel frames, punching not only affects the appearance of the product, but also directly affects the efficiency and strength of assembly. The punching line can meet the needs of high-efficiency and mass production and promote the development of the new energy industry.

1. Efficient production

One of the biggest advantages of the metal perforated machine is its efficient production capacity. The perforated metal production line can complete the punching of a large number of metal sheets in a short time through a fully automated process. The high-speed operation, automatic feeding, precise control and stable operation of the equipment enable it to maintain stable and efficient output under high-intensity production requirements.

|

|

|

2. High-precision processing

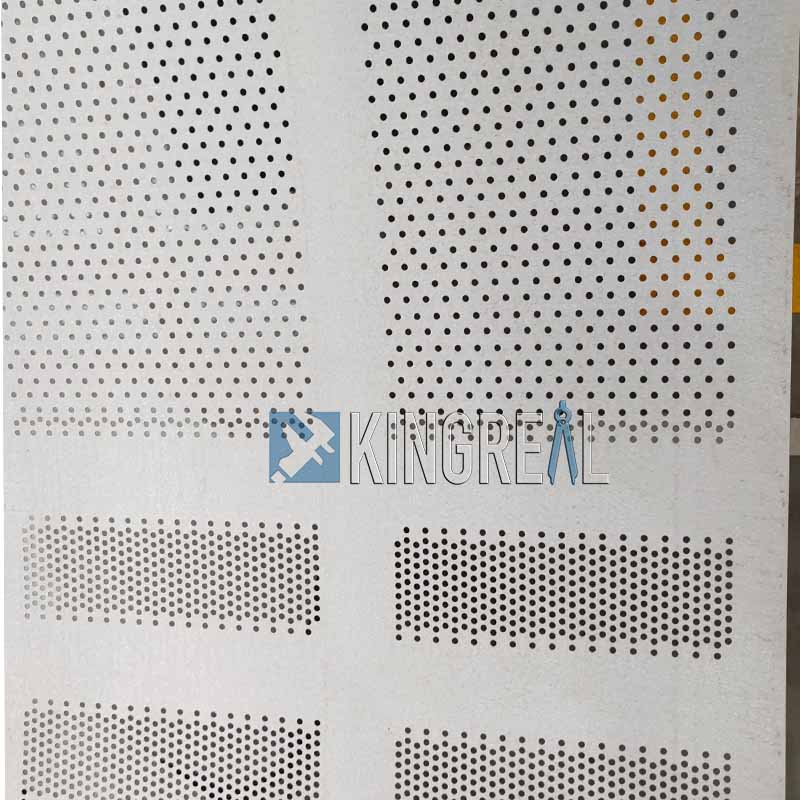

Another important feature of the sheet metal perforation machine is its superior processing accuracy. With advanced CNC systems and high-quality molds, the perforated metal production line can accurately punch holes on metal plates, and the hole diameter, hole spacing and arrangement can be set according to requirements. The precise control system and high-precision molds greatly reduce the dimensional error of the punching process, ensuring that the hole position of each metal plate can be highly consistent.

|

|

|

3. Diversified production

The flexibility and diversity of the perforated metal production line enable it to provide customized solutions under different production requirements. By replacing the punching mold, enterprises can produce a variety of metal sheets with different types and hole diameters according to the needs of different products. This means that a metal perforated machine can not only meet the needs of a single hole type, but also can be quickly converted through mold replacement to adapt to different market needs.

|

|

|

4. Reduce manual operation

The automated operation of the sheet metal perforation machine effectively reduces labor costs and reduces human errors. In traditional manual punching, the accuracy of the hole position may be unstable due to differences in operator experience and skills. The automated perforated metal production line uses precise program control and sensor monitoring to ensure that each punching meets standard requirements, significantly reducing product defect rates caused by human factors.

|

|

|