|

As the name implies, the medium gauge cut to length line is a production line for precise cutting of medium thickness metal plates. With the continuous development of industrial manufacturing, medium gauge cut to length machines have strong market demand in Indonesia, the Philippines, India, the United States, the United Kingdom, Australia and other countries. This article will introduce the relevant information of the medium gauge cut to length line in detail to help you understand this equipment more comprehensively. If you are interested in the medium gauge cut to length machine and want to get more relevant parameter information, please contact BRUTE SLTEEL SLITTER! |

|

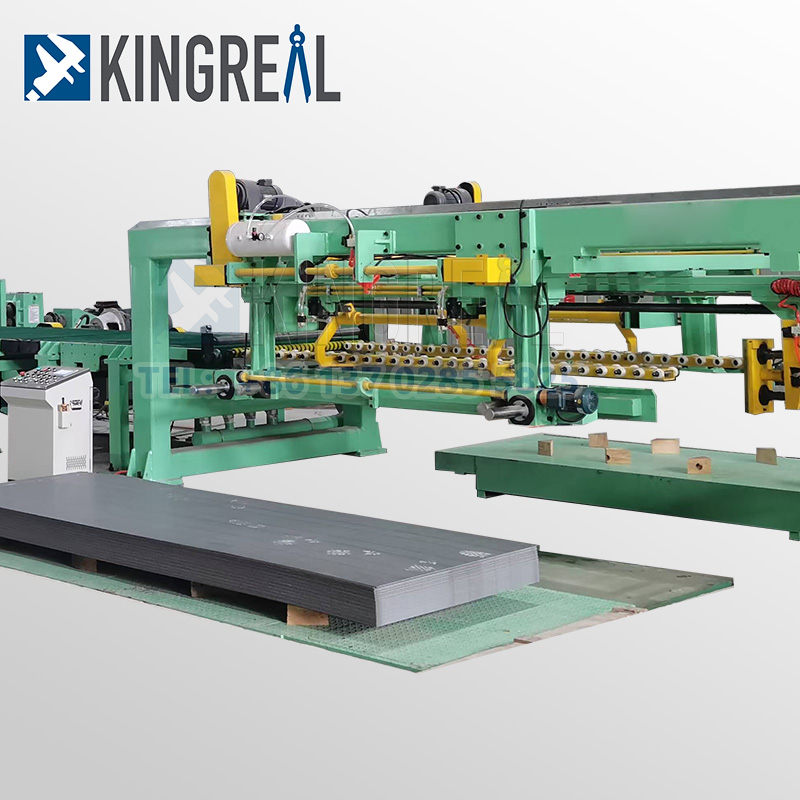

BRUTE SLTEEL SLITTER medium gauge cut to length machine is designed for precise cutting of metal coils with a thickness of 0.3-6MM. It can handle a variety of metal materials, including stainless steel, steel, cold rolled, hot rolled, etc. In order to meet customers' needs for medium gauge cut to length lines, BRUTE SLTEEL SLITTER has equipped this medium gauge cut to length machine with independent straightening machines and feeding units.

1.1 Main functions of medium gauge cut to length line

|

The configuration of this medium gauge cut to length machine has the following main functions: Unwinding for medium gauge cut to length line: Unwind the metal coil from the reel and prepare it for subsequent processing. Leveling for medium gauge cut to length machine: Use a straightening machine to level the coil to ensure flatness during the cutting process. Feeding for medium gauge cut to length line: Feed the metal material into the shearing device at a set length. Sizing for medium gauge cut to length machine: Accurately control the shearing length of each piece of metal according to user needs. Horizontal shearing for medium gauge cut to length line: Cut the metal material horizontally to form the required sheet. Stacking for medium gauge cut to length machine: Automatically sort and stack the cut sheets for subsequent processing. |

|

1.2 Automatic medium gauge cut to length line

The medium gauge cut to length machine is controlled by a PLC numerical control system, combined with a DC motor and a rotary encoder to achieve precise length control. Users can enter the order quantity, length and speed in the human-machine interface of the PLC system. When the shearing quantity reaches the set value, the medium gauge cut to length line will automatically stop. This efficient automation design not only improves production efficiency, but also greatly reduces manual intervention, and is simple to operate and easy to use.

The medium gauge cut to length line is very popular in the market, mainly due to the following advantages:

|

2.1 Strong equipment production capacity |

According to the user's process requirements and production efficiency requirements, the medium gauge cut to length machine can be equipped with equipment with appropriate power to ensure that the production capacity meets the needs of users. This flexibility enables the medium gauge cut to length line to adapt to production tasks of different scales and types. |

|

2.2 Low operating cost |

The medium gauge cut to length machine uses a hydraulic system instead of the traditional mechanical drive method, which is energy-saving and efficient. The use of the hydraulic system not only reduces the operating cost of the medium gauge cut to length line, but also improves the accuracy and reliability of shearing. |

|

2.3 Intelligent production |

The entire set of medium gauge cut to length machine adopts a PLC touch screen control system, and users only need to operate simply to complete the setting of all programs. This highly automated production capacity enables the forming process to be completed in one loading, greatly improving production efficiency. |

In order to ensure the long-term and stable operation of the medium gauge cut to length machine, maintenance and lubrication are essential. Here are some maintenance suggestions:

Regular lubrication: If the shearing unit is in standby mode for a long time, it is recommended to lubricate it every six months. If it is used frequently, it should be lubricated every 10-30 days to improve the use efficiency of the shearing device and extend its service life.

Check the medium gauge cut to length line status: Regularly check the various components of the medium gauge cut to length machine, including motors, hydraulic systems, cutters, etc., to ensure the normal operation of the medium gauge cut to length line and avoid production stagnation caused by failures.

Cleaning and maintenance: Keep the medium gauge cut to length machine clean, regularly clean up the metal chips and dust generated during the production process to prevent affecting the normal operation of the medium gauge cut to length line.

|

4.1 Leveling machine for medium gauge cut to length machine The selection of leveling machine for medium gauge cut to length line should be determined according to the actual width, thickness and material of the material. It is very important to understand the correction capacity range of the leveling machine.

4.2 Feeder for medium gauge cut to length line The medium gauge cut to length machine usually uses an NC feeder. NC feeder is the preferred equipment for automatic medium gauge cut to length machine. It can flexibly set parameters such as feeding step, speed, number of times and shearing time, and supports multi-stage feeding setting, which is convenient for user operation.

4.3 Cut to length machine for medium gauge cut to length line Shearing machines are usually divided into mechanical and hydraulic. Customers can choose the appropriate model according to their own needs. Hydraulic shearing machines usually have better performance and are suitable for mass production, while mechanical shearing machines are suitable for small-scale production.

|

|

|

4.4 Conveyor belt for medium gauge cut to length machine The conveyor belt of the medium gauge cut to length line is usually a belt conveyor belt. After the shearing machine is sheared, the sheared sheet is automatically conveyed. Customers can choose the appropriate conveyor belt width according to the actual material.

4.5 Stacking table for medium gauge cut to length machine Medium gauge cut to length lines are generally equipped with stacking tables, and the materials can automatically fall into the product frame in the stacking table after conveying. Users can also select automatic lifting devices, photoelectric devices and blowing devices according to their needs to improve production efficiency.

|

|

The medium gauge cut to length machine is an efficient and intelligent shearing equipment, which is widely used in the metal processing industry. Its precise cutting ability and efficient automatic control make it popular in the market. Through reasonable maintenance and selection of suitable medium gauge cut to length line configuration, users can give full play to the advantages of the medium gauge cut to length machine, improve production efficiency and reduce operating costs. If you have further needs or questions about the medium gauge cut to length line, please feel free to contact BRUTE SLTEEL SLITTER, we will wholeheartedly provide you with professional services and support.