|

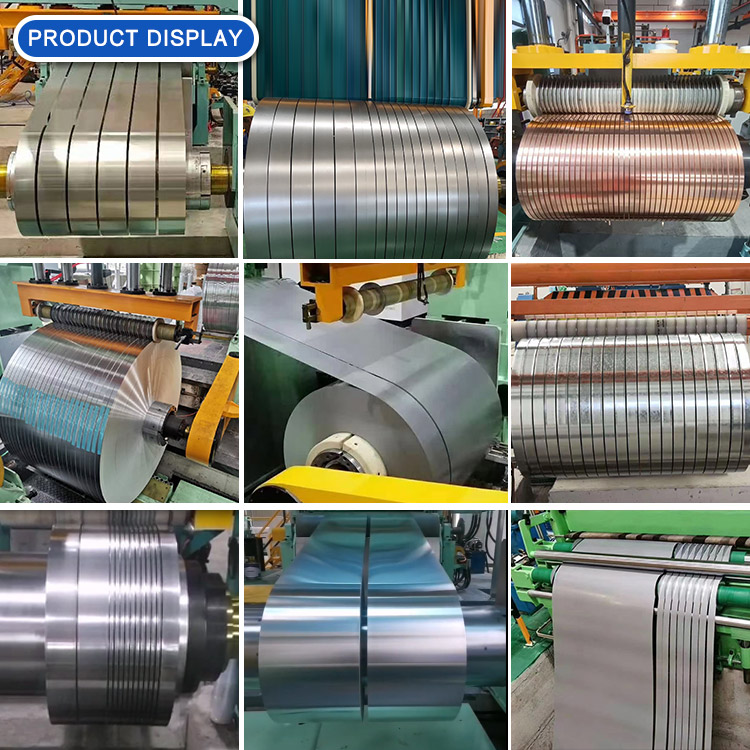

BRUTE STEEL SLITTER light gauge coil slitting lines are engineered to precisely slit large metal coils into narrower strips, tailored to satisfy customer production demands. These light gauge coil slitting machines utilize rotary knives and an automated control system to ensure every cut of the metal coil meets exact dimensional specifications. This type of light gauge coil slitting line can process a variety of different metal materials, including but not limited to: Carbon steel, Stainless steel, Aluminum, Copper, Brass and other alloys, etc. The narrow strips slit by the light gauge coil slitting machine are very suitable for downstream manufacturing processes such as stamping, forming or tube production. |

|

|

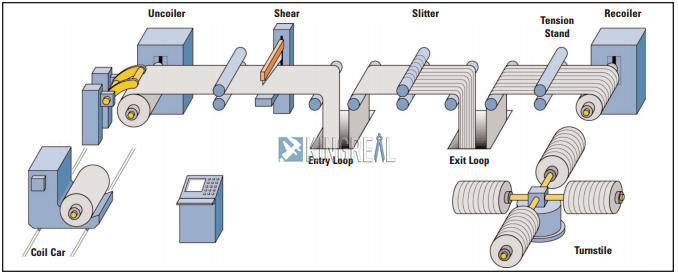

In terms of equipment composition, the light gauge coil slitting machine mainly includes a spindle system, upper and lower knife shafts, a transmission system, a control system and other auxiliary components. The spindle is the core component of the light gauge coil slitting line. It is usually supported by high-precision bearings and can rotate at high speed. Multiple blades are installed on the spindle to shear metal coils. The upper and lower knife shafts can adjust the distance between the blades to accommodate metal coils of different widths. They are usually driven by servo motors and can accurately control the shearing width. The transmission system is responsible for transmitting the power of the main shaft to the upper and lower blade shafts so that the blades can rotate synchronously. It is usually composed of components such as chains and gears and needs to have high stability and reliability. The control system is the "brain" of the light gauge coil slitting machine, which is responsible for controlling the start, stop, speed adjustment and other operations of the machine. Modern light gauge coil slitting lines usually use PLC control systems, which can realize automatic control and intelligent management. In addition, the light gauge coil slitting machine also includes auxiliary components such as the frame, feeding device, and winding device to ensure the stable operation and efficient processing of the light gauge coil slitting line.

In terms of working principle, the light gauge coil slitting machine moves the metal coil at a certain speed through the traction of the mechanical roller, and then the cutting tool is used for shearing. The feeding device feeds the metal sheet into the cutting area, and the cutting device consists of a set of high-speed rotating blades to cut the metal sheet into strip products. The winding device rolls the cut strip products into coils to complete the entire processing process. The light gauge coil slitting line has the advantages of easy operation, high production efficiency, and good cutting quality, which can meet the processing needs of different scenarios. |

|

①The light gauge coil slitting line can accurately slit metal coils within the thickness range of 0.2-3mm.

②The light gauge coil slitting machine has a high degree of automation, and can also be equipped with feeding trolleys, laminating devices and other components according to the actual production needs of customers.

③In order to better ensure the production safety of workers, BRUTE STEEL SLITTER can launch light gauge coil slitting lines with protective shield.

④The light gauge coil slitting machine can cut up to 40 narrow strips at a time.

|

|

|

Against the background of the transformation of manufacturing industry to refinement and efficiency, the light gauge coil slitting line is gradually becoming a key equipment in many industrial fields. Its application scenarios have extended from the traditional steel industry to a wider range of fields such as automobile manufacturing, home appliance production, and construction engineering, and the market demand has shown a steady growth trend. Taking the steel industry as an example, precise cutting technology is the core link of steel plate processing-whether it is the primary processing of cold-rolled steel plates or the secondary cutting of galvanized plates, the light gauge coil slitting machine has become an indispensable "cutting division" in the production line with its high-precision slitting ability. In the field of automobile manufacturing, the high-strength thin steel plates required for body panels and the precision metal sheets required by the home appliance industry also rely on this type of light gauge coil slitting line to complete the transformation from coils to finished strips, and its application breadth continues to expand with the upgrading of downstream industries.

The market penetration of light gauge coil slitting machines has increased, not only driven by demand, but also benefited from the iterative upgrading of industrial technology. Early slitting equipment mostly relied on manual debugging, and slitting accuracy and efficiency were limited by the level of operation; nowadays, modern light gauge coil slitting lines have deeply integrated the Internet of Things, intelligent sensing and CNC system technology: by real-time monitoring of coil tension, temperature and other parameters, the system can automatically adjust the tool gap and slitting speed, not only controlling the slitting error within the millimeter level, but also shortening the processing time of a single coil of material by more than 30%. This "intelligent + automated" technology empowerment not only reduces the labor costs of enterprises, but also improves product consistency, and promotes the upgrade of light gauge coil slitting machines from "optional equipment" to "must-have equipment".

It is worth noting that with the tightening of global environmental protection policies, the green transformation of the metal processing industry has entered an accelerated period, and the design and manufacturing standards of light gauge coil slitting lines have also been adjusted accordingly. Traditional light gauge coil slitting machine is gradually being eliminated by the market due to high energy consumption and high waste, and is being replaced by new light gauge coil slitting lines equipped with energy-saving and consumption-reducing technology modules. For example, some companies have reduced equipment energy consumption by 20%-25% by optimizing motor energy efficiency and introducing heat recovery systems; some manufacturers have adopted low-friction tool materials and automatic waste recovery devices to reduce metal scraps in the production process by more than 40%. This type of "green light gauge coil slitting machine" that meets environmental protection requirements is becoming a priority option for downstream companies when bidding, and has also opened up a new growth track for the industry.

|

|

|

Questions to Consider:

√ What types and thicknesses of materials need to be processed?

√ What is the desired capacity?

√ How many slitting widths are typically required?

√ Do you need automation or manual control about light gauge coil slitting line?

√ How much space is available in your factory?