Last week, BRUTE STEEL SLITTER's metal cut to length line was successfully manufactured and passed a series of rigorous tests and quality inspections by BRUTE STEEL SLITTER technicians before leaving the factory. The BRUTE STEEL SLITTER technical team conducted a full range of test runs on the metal cut to length line, focusing on verifying the running speed, finished product accuracy, stability and other key performance indicators of the shearing line to ensure that the equipment can fully meet customer needs and production standards.

After confirming that the cut to length machine has excellent performance and meets customer requirements, this high-quality cut to length machine was carefully packaged and shipped to the Russian customer factory smoothly.

BRUTE STEEL SLITTER is a leading supplier specializing in the manufacture of coil slitting machines and metal cut to length lines. With more than 20 years of rich industry experience, it has always been committed to providing customers with high-quality machines and equipment. During the production process, BRUTE STEEL SLITTER strictly controls key indicators such as equipment production quality, running speed, service life and finished product accuracy to ensure that every piece of equipment shipped can meet or even exceed customer expectations.

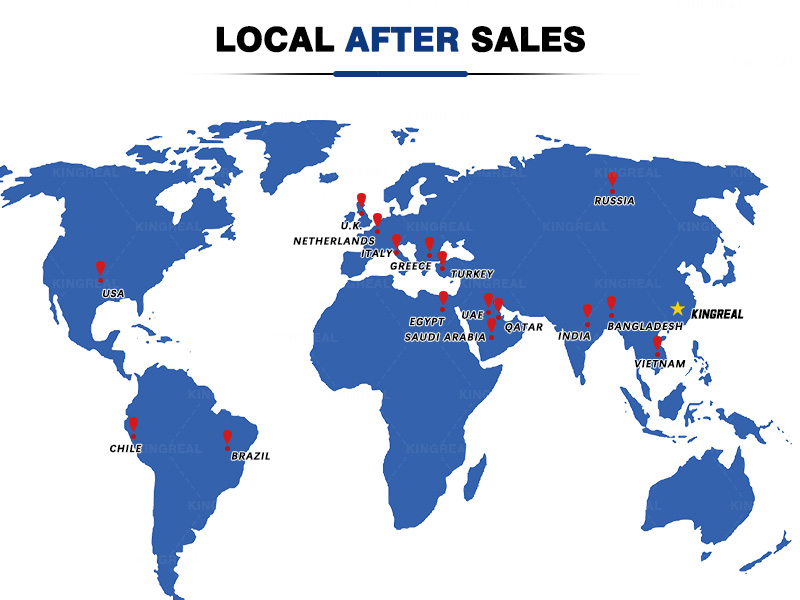

This rigorous and serious manufacturing attitude has won BRUTE STEEL SLITTER's metal coil slitting machines and metal cut to length lines wide acclaim and high trust from customers around the world. At present, BRUTE STEEL SLITTER's metal cut to length line has been successfully sold to many countries.

The equipment has stable performance and excellent efficiency, and is deeply favored by users. At the same time, BRUTE STEEL SLITTER has established long-term and stable cooperative relations with many customers, and continues to provide them with efficient and reliable production solutions.

In the future, BRUTE STEEL SLITTER will continue to uphold the concept of "quality first, customer first", continue to innovate and optimize, and create greater value for global customers!

1. Three-in-one cut to length machine sent to German customer factory

When the German customer found BRUTE STEEL SLITTER, the demand was a cut to length machine that saved waiting time for manual operation. After a detailed conversation between BRUTE STEEL SLITTER engineers and customers, the customer's production needs were confirmed. BRUTE STEEL SLITTER recommended the three-in-one shearing line to the customer.

BRUTE STEEL SLITTER's three-in-one metal cut to length line integrates unwinding, leveling, and feeding. The servo system controls the movement of the feeding device to achieve accurate positioning of the plate and continuous feeding into the shearing area, thereby realizing the continuous cutting and blanking production and processing of the plate. This greatly improves production efficiency and reduces the waiting time for manual operation.

2. Heavy-duty metal cut to length lines are sent to Brazilian customer factories

Brazilian customers' demands are that the metal raw material coils are too thick to be put into ordinary metal cut to length lines for metal processing. BRUTE STEEL SLITTER staff proposed that KNGREAL's heavy gauge cut to length line can accurately shear various metal coils with a thickness of 6-20mm, which can meet customer needs.

3. High-speed metal cut to length lines are sent to British customer factories

British customers need machines that can quickly shear metal sheets. He learned that BRUTE STEEL SLITTER has a high-speed metal cut to length line, so he came to ask. BRUTE STEEL SLITTER staff told customers the metal cut to length line parameters of BRUTE STEEL SLITTER's high-speed metal cut to length line one by one. BRUTE STEEL SLITTER's high-speed metal cut to length line can reach the fastest shearing speed of 75m/min. It meets customer requirements.