Metal coil slitting machines are indispensable and important equipment in the metal processing industry and are widely used in automobile manufacturing, home appliance production, building decoration and other fields. BRUTE STEEL SLITTER is a professional manufacturer of coil slitting equipment and can provide various types of metal coil slitting machines according to customers' actual needs.

With the continuous improvement of efficiency and quality requirements in industrial production, how to improve the efficiency of slitting machines has become a core issue for enterprises. This article will discuss in detail how to improve the efficiency of the metal coil slitting machine and create greater economic value for the enterprise from four aspects: equipment optimization, operation process improvement, technology upgrade and maintenance.

1. Choose the appropriate slitting machine type

Different types of coil slitting equipment differ in design and functionality. Enterprises should choose appropriate equipment based on their own production needs. For example:

- Ordinary metal coil slitting machine: suitable for small and medium-sized batch production, with low cost but relatively low efficiency.

- High-speed coil slitting equipment: suitable for mass production, the slitting speed can reach more than 200 meters per minute, and the efficiency is significantly improved.

- Thick plate coil slitting equipment: designed for thicker metal materials and suitable for special fields.

2. Improve the automation level of equipment

Modern slitting machines mostly use PLC control systems to support automated operations. By upgrading the automation system, the equipment can set parameters with one click and automatically adjust blade spacing and tension, reducing manual intervention and improving production efficiency.

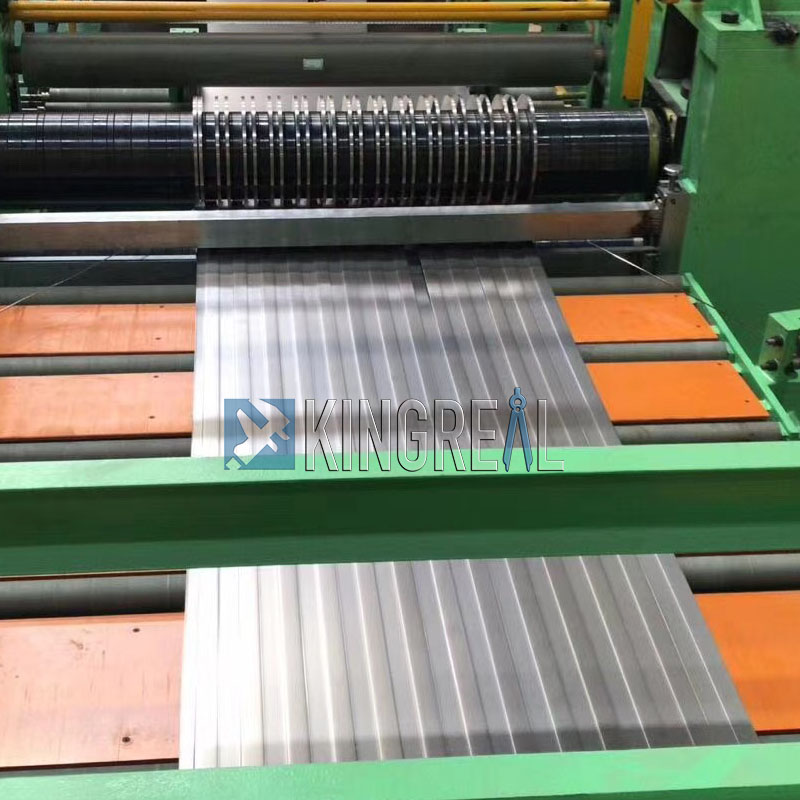

3. Optimize slitting blade design

The slitting blade is the core component of the equipment, and its performance directly affects the slitting quality and efficiency. Using high-strength alloy steel blades and grinding them regularly can maintain the sharpness of the blades, reduce cutting resistance, and increase the slitting speed.

4. Improve the winding system

The efficient winding system can quickly wind the slit metal strips into rolls to avoid affecting production efficiency due to too slow winding speed. The automatic tension adjustment device ensures tight and even winding.

|

|

|

1. Optimize raw material preparation

- Before production begins, ensure that the quality of the metal coil meets the requirements to avoid material defects (such as uneven surface or excessive internal stress) affecting the slitting effect.

- Check in advance whether the weight and width of the roll are suitable for the equipment to reduce downtime adjustments caused by material inconsistencies.

2. Reduce tool changing and adjustment time

- Properly plan production batches to minimize blade spacing adjustments and tool changing frequency.

- Equipped with a quick tool change system, blade replacement and position adjustment can be completed in a short time, reducing downtime.

3. Improve operator skills

- Provide professional training to operators to become proficient in equipment operation and troubleshooting skills.

- Operators should understand the operating principles of the metal coil slitting machine and be able to quickly judge and solve problems to reduce efficiency losses caused by improper operation.

4. Real-time monitoring of the production process

- Install an online monitoring system to monitor the operating status of the equipment in real time, including speed, tension, blade wear, etc.

- Detect abnormalities in time through the monitoring system to reduce downtime.

|

|

|

1. Introduce intelligent technology

- Use artificial intelligence (AI) and Internet of Things (IoT) technologies to intelligently transform slitting machines.

- The intelligent system can analyze production data, optimize parameter settings, and improve equipment operation efficiency.

2. Optimize the drive system

- Upgrade the traditional mechanical drive system to a servo drive system. The servo motor can accurately control speed and tension, improving the stability and efficiency of slitting.

- The servo system can also reduce energy consumption and reduce operating costs.

3. Adopt high-precision blade positioning system

- Equipped with a high-precision blade positioning device to ensure rapid and accurate blade spacing adjustment and avoid rework due to errors.

4. Upgrade edge material processing device

- If the edge materials generated during the slitting process are not handled properly, production efficiency will be affected. Upgrade the edge material recycling device to automatically collect and process edge materials to keep the production line clean.

|

|

|

1. Check the blade regularly

The sharpness of the blade directly affects the slitting efficiency and quality. Enterprises should establish a regular inspection and maintenance system for blades, and promptly replace or grind blades according to usage.

2. Lubrication and maintenance

The bearings, guide rails and transmission parts of the metal coil slitting machine need regular lubrication to reduce wear and operating resistance and extend the life of the equipment.

3. Cleaning equipment

After each production, the operator should thoroughly clean the equipment, especially the blades and transmission parts, to avoid residual metal debris from affecting the next production.

4. Check the electrical system

Regularly check electrical components and circuits to ensure stable operation of the control system and avoid downtime due to electrical faults.

5. Develop a preventive maintenance plan

Companies should develop detailed equipment maintenance plans, including regular inspections, parts replacement and performance testing. Through preventive maintenance, sudden failures can be reduced and equipment utilization can be improved.

|

|

|