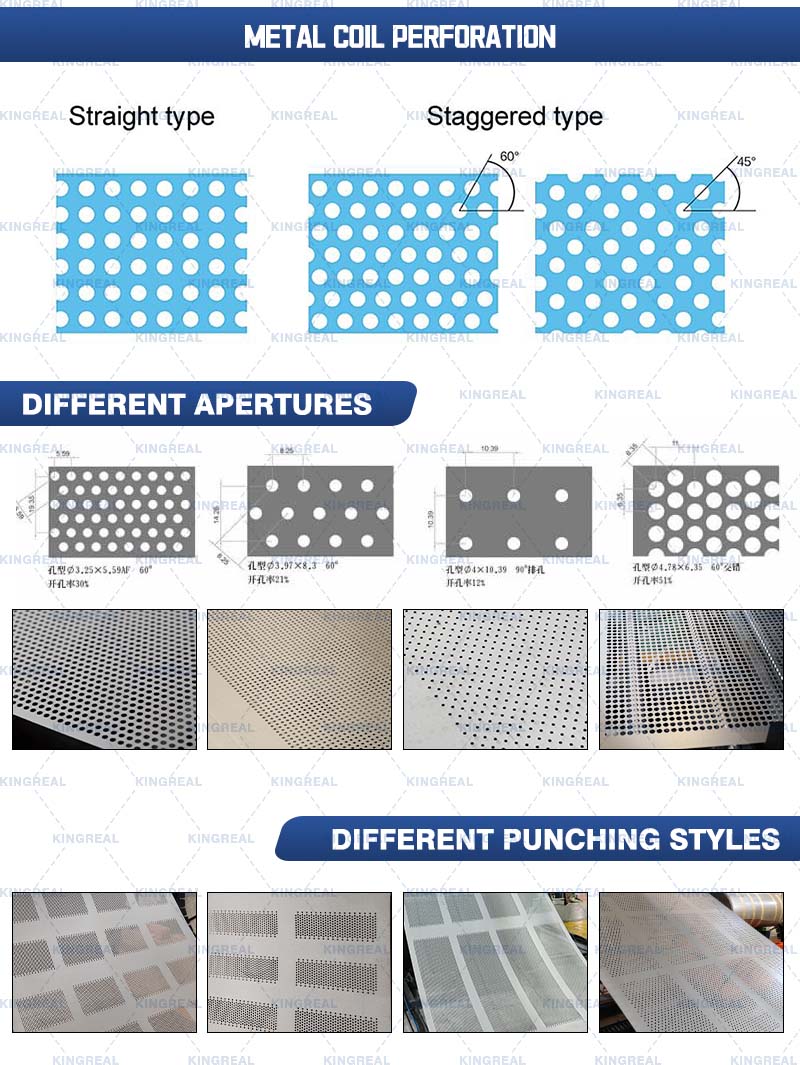

Metal perforating machines are suitable for punching metal plates of various materials. For example, iron plates, stainless steel plates, copper plates, aluminum plates, galvanized plates, etc. And holes of different shapes and apertures can be punched according to customer needs.

Common punchable shapes include round holes, oblong holes, square holes, triangular holes, diamond holes, hexagonal holes, cross holes, etc.

There are various sheet metal perforated machines on the market. For different production needs and processing characteristics, the choice of metal perforating machines often confuses many customers. When faced with many models, brands and configurations, how can customers make a reasonable choice? This article will share some practical suggestions to help customers choose the most suitable sheet metal perforated machine based on actual production needs, price, quality and other factors.

1. Actual production needs

Before choosing a sheet metal perforated machine, you first need to clarify your production needs. Metal perforating machines can usually be divided into three categories according to their functions and application areas: metal ceiling perforation lines, coil perforated rewinding production lines and metal sheet coil perforated cutting production lines. Different types of metal perforating machine are suitable for different production needs, and the choice should be made according to your specific needs.

(1) Metal ceiling perforation line: It is usually used for the processing of metal ceilings, especially for metal ceiling production lines that require efficient punching. If you mainly produce metal ceilings or similar building materials, it would be more appropriate to choose a metal ceiling perforation line.

(2) Metal sheet coil perforated cutting production line: It is suitable for production processes that require punching materials and cutting them to a fixed length. If your production needs include cutting the punched product to a fixed length, it can effectively improve efficiency.

(3) Coil perforated rewinding production line: It is mostly used for processing metal strips. The material is rolled up directly after punching, which is a production mode that requires the material to be rolled into a coil. If your production process requires the metal sheet to be rolled or stored in coils after punching, it will be more appropriate to choose a coil perforated rewinding production line.

In addition to choosing the type, you should also consider the punching shape and aperture of the production line, especially if you have special punching requirements (such as non-standard hole shapes or specific apertures). When choosing, you must communicate clearly with the equipment manufacturer and provide detailed drawings to ensure that the metal perforating machine can meet your requirements.

In addition, the production speed of the metal perforating machine is also a very important factor. For customers with large-scale production, high-speed sheet metal perforated machines are very important because they can ensure efficient production capacity. For small-scale punching production, speed may not be the primary consideration, so it is not necessarily necessary to choose a high-speed sheet metal perforated machine. Choose the most suitable machine according to the production scale and efficiency requirements.

2. Reasonable price

Price is one of the factors that customers cannot ignore when choosing a sheet metal perforated machine. Many customers are often affected by price when choosing a machine, especially when the budget is limited. However, price is not the only criterion. When choosing a machine, you should consider the overall cost-effectiveness and make a judgment based on the following factors:

(1) Your own budget: First of all, you should clarify your budget range and determine the acceptable price range. Don't blindly pursue the lowest price, and don't think that the quality must be guaranteed because of the high price. The most suitable sheet metal perforated machine is the most cost-effective machine.

(2) After-sales service cost: The machine needs long-term maintenance after purchase, and after-sales service is an important consideration for customers when choosing equipment. Consider the maintenance cost of the equipment, the replacement cost of parts, and the maintenance service provided by the manufacturer. Choosing a manufacturer that provides long-term warranty and quick response can reduce future maintenance costs and downtime losses.

(3) Daily use cost: The power consumption of equipment operation, the replacement frequency of wear parts, the training cost of operators, etc. will affect the daily use cost of the sheet metal perforated machine. Therefore, try to choose those metal perforating machines with mature technology and easy maintenance to reduce daily operating costs.

|

|

3. Quality

Quality is the most critical factor when choosing a metal perforating machine. After all, no one wants to spend a lot of money to buy equipment that often breaks down, resulting in production stoppages, wasting time and money. How to evaluate the quality of a metal perforating machine? The following aspects can help you judge the quality of the machine:

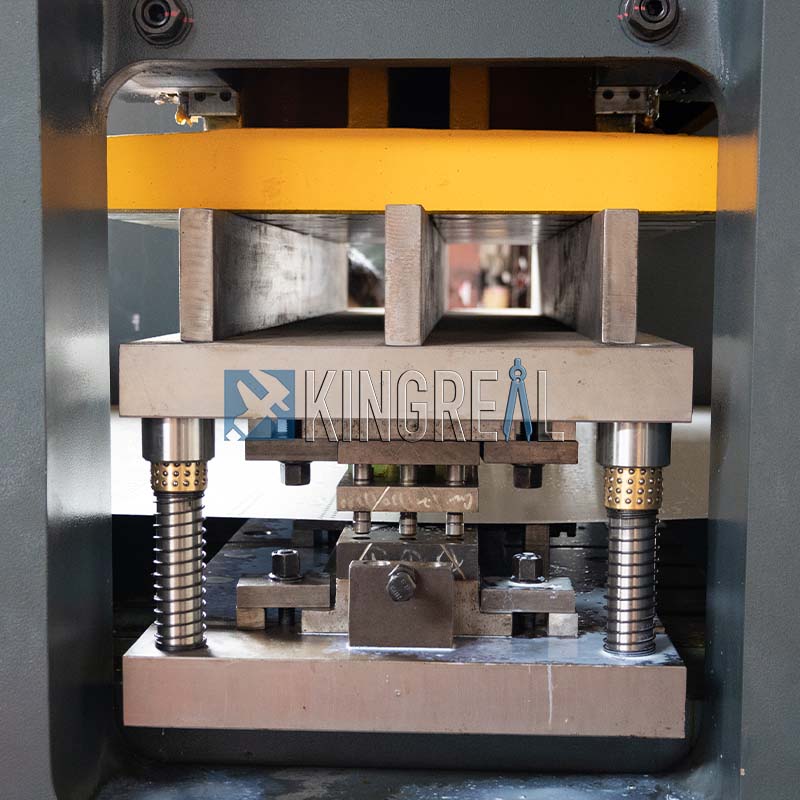

(1) Ask about the raw materials used in the manufacturing: Understand whether the raw materials used in the sheet metal perforated machine meet the standards. High-quality materials can ensure that the machine is more durable and stable. Many high-quality metal perforating machines use wear-resistant alloy steel, high-quality motors and hydraulic systems to ensure that the machine can run for a long time without failure.

(2) Visit the actual production line: If possible, you can directly visit the production workshop of the equipment manufacturer to understand the actual production of the machine. During the visit, you can see the production process and quality control of the equipment, understand whether the machine meets the production standards, and whether the equipment runs smoothly.

(3) Ask about existing customer cases: By asking the manufacturer about existing customer cases, you can understand the actual operation of the equipment and customer feedback. Through the experience of other customers, you can understand the advantages and disadvantages of the machine, as well as the performance of the equipment in long-term operation.

(4) Check the machine certification: Formal equipment manufacturers usually provide relevant certification certificates for the equipment to prove that the equipment meets national and industry safety standards. When purchasing, you can ask the manufacturer to provide relevant certificates to ensure that the equipment meets quality and safety requirements.

(5) Choose an experienced and reputable manufacturer: Choosing an experienced and reputable manufacturer is the key to ensuring the quality of the equipment. Experienced manufacturers usually have more mature technology and reliable products, and their after-sales service is more complete, which can effectively reduce various problems in production.

|

|

|