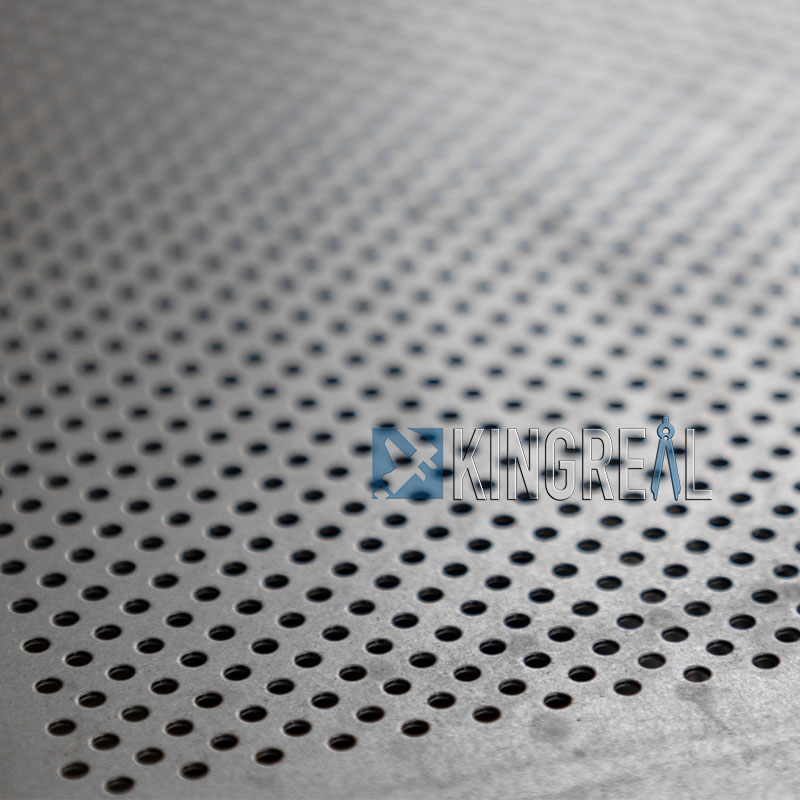

There are many metal hole sheets on the market, and a series of products are processed based on it. So how are these metal hole sheets made?

Metal hole sheets are made by coil perforation line. The stamping process involves multiple steps, including cutting, punching, bending and forming. During the punching process, the sheet metal punch cuts the required shape from the metal sheet. The punching shape and aperture vary, which can be achieved by replacing different punching dies.

Compared with other mechanical equipment, the metal perforated machine has the advantages of fast processing speed, high processing accuracy, and fast one-time forming.

|

|

(1) Raw material preparation

- Material selection: Select suitable metal plates, common ones are stainless steel, aluminum alloy, iron plate, etc. Material thickness, width and length should be selected according to customer needs and product requirements.

- Material cutting: If the size of the metal plate is large, it needs to be initially cut by a shearing machine or other equipment to make the plate meet the size required for punching.

(2) Feeding system

- The prepared metal plate is fed into the metal perforated machine through an automatic feeding system. This process may involve rollers or conveyor belts to ensure that the metal sheet is smoothly transferred to the next process.

- The feeding system is usually equipped with precision sensors to detect the arrival of the sheet and ensure that each sheet enters the correct position of the coil perforation line.

|

|

(3) Metal perforated machine operation

- Set punching parameters: Set the working parameters of the coil perforation line according to the design requirements, including hole diameter, hole spacing, punching speed, etc.

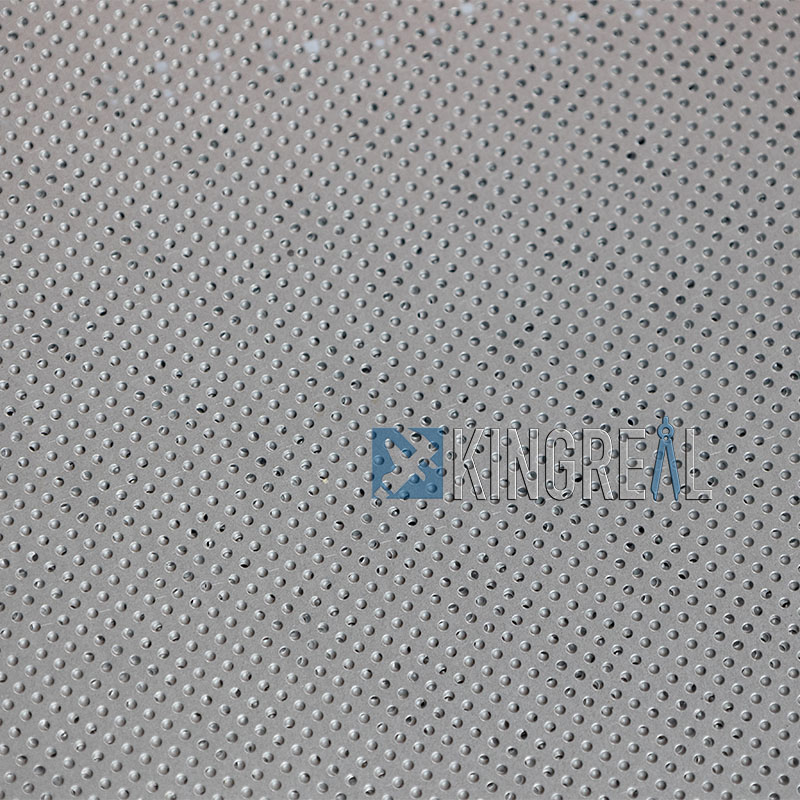

- Punching process: After the metal sheet enters the metal perforated machine, the machine punches the metal sheet through the die to form a preset hole shape. The coil perforation line can perform single or multiple punching operations, and choose the appropriate process according to production needs.

- Single hole punching: Punching one hole at a time, suitable for simpler hole types.

- Multi-hole punching: Multiple holes are punched at the same time, suitable for mass production and improving production efficiency.

- Automatic adjustment: Some high-end coil perforation lines also have the function of automatically adjusting the die and pressure to cope with metal plates of different thicknesses and materials.

|

|

(4) Hole position detection and quality control

- During the punching process, real-time hole position detection is required to ensure that the accuracy and position of the holes meet the design requirements. The automated detection system can quickly identify the size and position of the holes, and make timely adjustments if there is a deviation.

- Some production lines may also be equipped with visual inspection equipment to perform precise inspections on the holes of each metal plate to ensure that there are no defects.

(5) Feeding system

- After punching, the metal sheet is sent out through the feeding system. The feeding system is usually equipped with an automatic discharge device to ensure that the processed metal sheet is quickly and safely removed.

- Some punching lines are also equipped with a sorting system that can separate different types of sheets according to different processing requirements.

(6) Post-processing process

- Deburring: The punched sheet may have burrs, which need to be deburred to ensure that the edge of the sheet is smooth and avoid sharp burrs from affecting subsequent processing.

- Cleaning and inspection: After deburring, the sheet may also need to be cleaned to remove impurities such as metal chips and oil generated during the stamping process to ensure product quality.

|

|

|

|

(7) Packaging and storage

-Pack the metal sheets that have been punched and post-processed, mark the product specifications, quantity and other information, and prepare to ship to customers or enter the downstream production link.

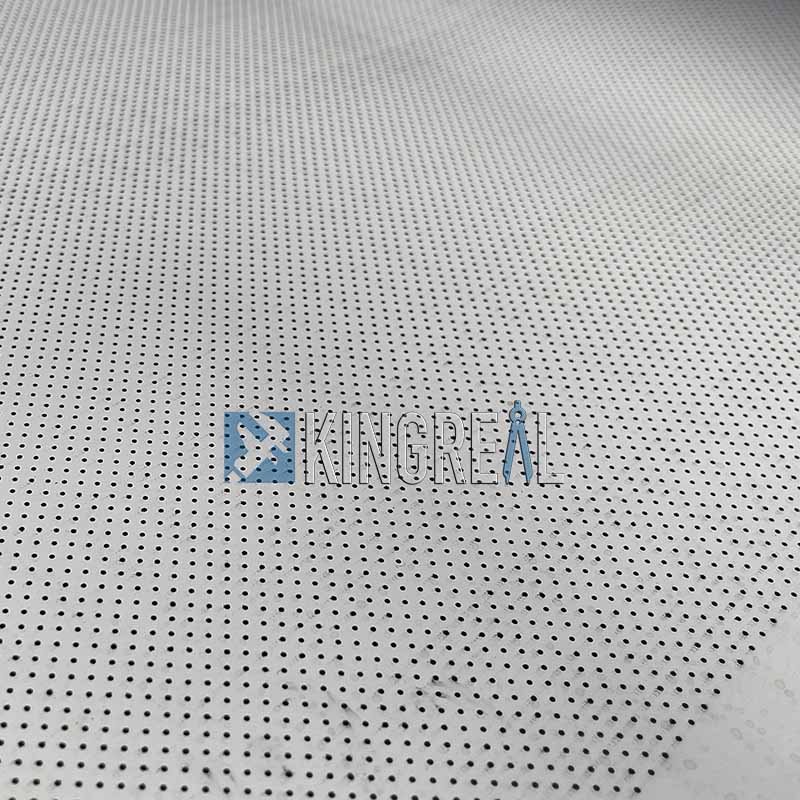

BRUTE STEEL SLITTER's coil perforation line can meet the different production needs of customers, and can provide customers with metal ceiling perforation lines, coil perforated rewinding production lines and metal sheet coil perforated cutting production lines.

Among them, the metal ceiling perforation line can be used with the metal ceiling production line to produce metal perforated ceilings. The coil perforated rewinding production line is to equip the production line with a rewinding machine, which is wound after the punching of the sheet is completed, and can be made into products such as punching filter elements. Metal sheet coil perforated cutting production line is to add a cutting station after the sheet is punched, and cut the punched sheet into the length required by the customer.

(1) Decoiler with feeding trolley. BRUTE STEEL SLITTER's metal perforated machine is equipped with a feeding trolley. When the metal coil is placed on the feeding trolley, it will be automatically transported to the decoiler to complete the unwinding, saving time and labor for loading metal coils, and improving the automation of the coil perforation line.

(2) Precision leveling machine. BRUTE STEEL SLITTER equips the coil perforation line with a precision straightener, which is composed of 9 rollers, 4 upper rollers and 5 lower rollers. The leveling device can level the coil, make the surface smooth, and improve the punching accuracy.

(3) High-speed coil perforation line. BRUTE STEEL SLITTER metal perforated machine can reach 100-180SPM. And this machine has a pneumatic brake system for high-speed and precise punching, and is equipped with a durable DC53 mold to ensure accuracy during continuous operation.

(4) BRUTE STEEL SLITTER is able to provide customized punching dies according to the customer's design drawings to meet a variety of different hole types and hole diameters. Whether it is round, square, rectangular or special-shaped holes, BRUTE STEEL SLITTER can provide professional solutions to meet the punching needs of various products.