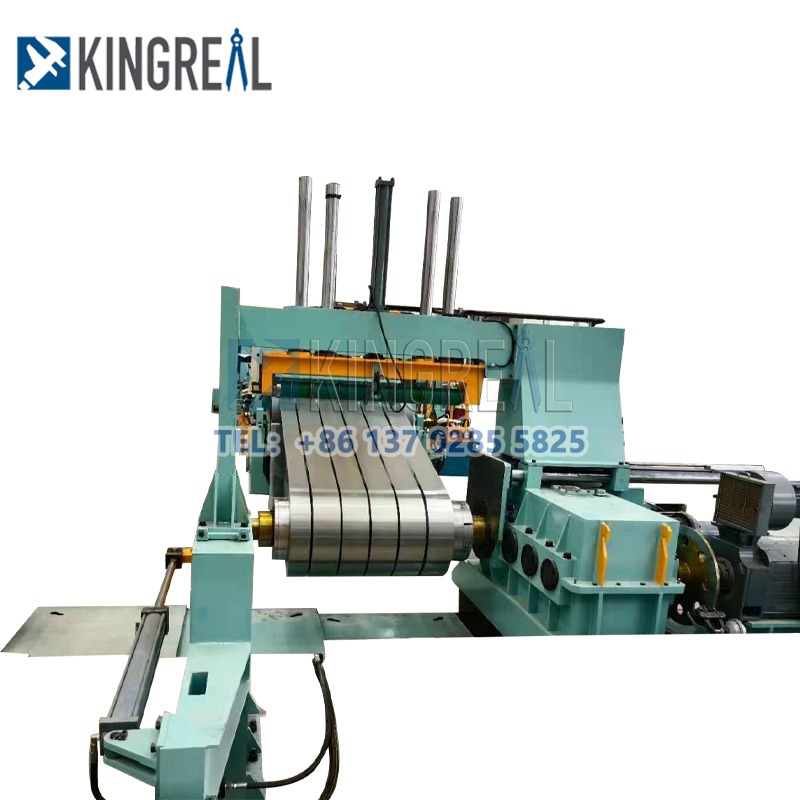

A coil slitting machine is a highly efficient device specially used to cut metal coils longitudinally into multiple narrow metal strips. It is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and various types of metal coils after surface coating. It is widely used in automobile manufacturing, home appliance production, building materials, packaging industry, aerospace and other fields. This equipment has become an important tool in the metal processing industry with its high efficiency, precision and multi-function characteristics.

The coil slitting line mainly consists of: loading trolley, decoiler, leveling machine, coil slitting machine, waste edge winding machine, tensioner, winding machine, unloading device, etc.

|

|

The coil slitting line has a large demand and wide application in the market, and it has an important position. The reason is:

1. Improve production efficiency

The coil slitting machine can complete the slitting of metal coils in a high-speed and precise manner, significantly improving production efficiency. Traditional manual cutting is time-consuming and labor-intensive, and has low precision. Modern coil slitting lines use automated operation, which can not only quickly complete mass production, but also ensure that each metal strip is of the same size, reducing waste and rework.

2. Adapt to multi-industry applications

Coil slitting machines play an important role in multiple industries:

1. Automobile manufacturing: Slitting metal strips are widely used in body manufacturing, parts production and other fields.

2. Home appliance production: Most of the metal parts in home appliances such as air conditioners and refrigerators come from slitting strips.

3. Building materials: Metal slitting strips are the basic materials for manufacturing building panels, ceilings, light steel keels and other products.

4. Packaging industry: Metal packaging materials, such as metal hoops, can materials, etc., usually need to be processed by coil slitting machines.

3. Optimize production processes

The use of coil slitting lines optimizes the production process of metal processing. Slitting metal strips can be directly used in subsequent processes such as welding, stamping, and bending without additional processing. This integrated processing mode reduces the intermediate links and improves the overall production efficiency.

4. Promote environmental protection and sustainable development

The coil slitting machine reduces resource waste and material loss through precise cutting and improved material utilization. In addition, many modern slitting machines adopt energy-saving design, which reduces energy consumption and contributes to environmental protection and sustainable development.

1. Meet diverse needs

Different industrial fields have diverse needs for the width and material of metal strips. The coil slitting machine can flexibly adjust the slitting width according to the specific requirements of customers, and is suitable for a variety of metal materials such as steel, stainless steel, aluminum, and copper. This versatility makes it a key equipment to meet diverse production needs.

|

|

|

2. Improve product quality

The coil slitting line is equipped with high-precision tools and advanced tension control systems to ensure that the cuts are smooth and burr-free during the slitting process, reducing damage to the surface of the material. High-quality slitting strips are easier to operate in subsequent processing, which helps to improve the quality of the final product.

3. Reduce production costs

Through efficient slitting processing, the coil slitting machine can minimize material waste and reduce production costs. In addition, the automated operation of the equipment reduces the reliance on manual labor, which not only reduces labor costs, but also reduces losses caused by human errors.

4. High performance and high flexibility

BRUTE STEEL SLITTER can customize coil slitting lines according to the actual production needs of customers. To adapt to large-scale production, BRUTE STEEL SLITTER has launched high-speed coil slitting machines with a maximum working speed of 230m/min, which is suitable for steel mills, service centers, automotive industries and other fields. In addition, BRUTE STEEL SLITTER engineers have also designed compact, simple coil slitting machines for low production capacity.

|

|

The following are BRUTE STEEL SLITTER's featured coil slitting machines that are widely praised by customers and in high demand:

- Thick Plate Coil Slitting Machine

- Medium Plate Coil Slitting Machine

- Heavy Gauge Coil Slitting Machine

- Narrow Strip Coil Slitting Machine

- Double Slitter head Coil Slitting Machine

- Belt Tension Coil Slitting Machine