In today's highly competitive manufacturing industry, enterprises have increasingly diversified needs for equipment. In particular, the particularity of the metal perforated machine determines the importance of customized services.

As an industry-leading sheet metal perforation machine manufacturer, BRUTE STEEL SLITTER fully recognizes that the specific needs of each customer are unique. Therefore, BRUTE STEEL SLITTER is committed to providing comprehensive customized services to ensure that customers' production needs are accurately met.

The biggest difference between metal perforated production line and other machines is that there are no identical machines in the world. Each metal perforating machine may have significant differences in parameter performance, processable material thickness and its application areas. This personalized demand makes customization particularly important.

1. Strong adaptability

During the production process, different factories often face different production needs. For example, some factories may need to process thicker materials, while others may focus on the processing of thin materials. Through customization, BRUTE STEEL SLITTER is able to design and manufacture the most suitable metal perforating machines for customers according to their specific needs. This flexibility not only improves production efficiency, but also reduces unnecessary waste of resources.

2. Improve production efficiency

Customized metal perforated production lines can better meet the factory's production process and reduce equipment commissioning time and production downtime. For example, for certain specific industries, BRUTE STEEL SLITTER can provide special metal sheet coil perforated cutting production lines or coil perforated rewinding production lines. These customized solutions can significantly improve production efficiency and help customers gain an advantage in the fierce market competition.

3. Comply with industry standards

Different industries have different requirements for equipment. Through customization, BRUTE STEEL SLITTER can ensure that each metal perforating machine not only meets the specific needs of customers, but also complies with relevant industry standards and safety regulations. This provides a reliable guarantee for customers' production activities.

BRUTE STEEL SLITTER's customization services cover a variety of options to meet the needs of different customers. Here are some common customization options:

1. Provide customized machines according to the actual production needs of customers

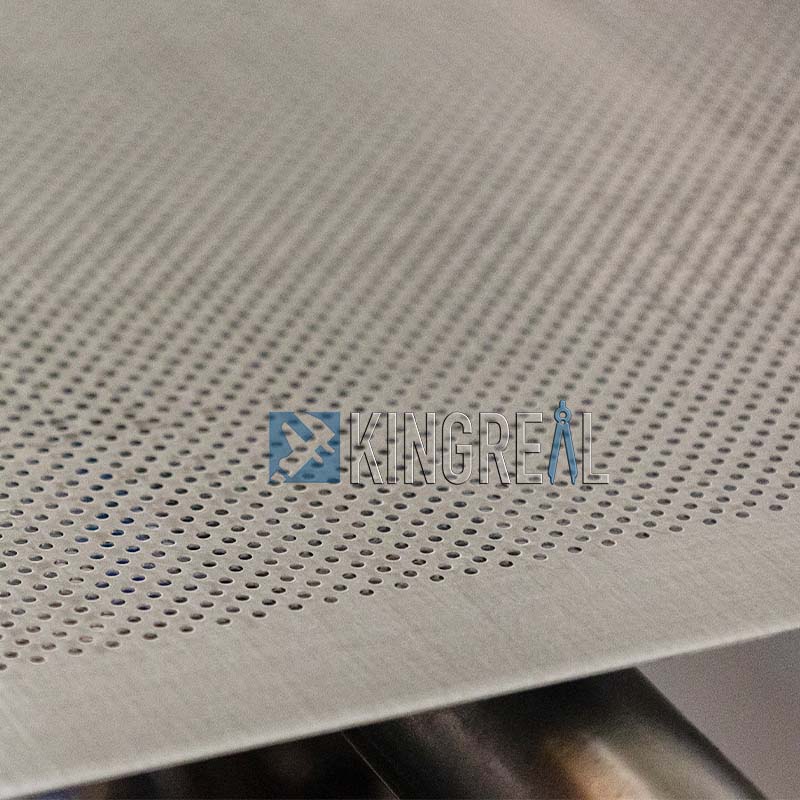

- Metal sheet coil perforated cutting production line: This type of production line is designed for customers who need to punch and shear materials. Its flexible configuration allows it to adapt to the processing needs of different thicknesses and material types.

- Coil perforated rewinding production line: Suitable for customers who need to roll punched materials. This customized solution can effectively improve the utilization rate of materials and reduce the complexity of subsequent processing.

- Metal ceiling perforation line: BRUTE STEEL SLITTER provides a special metal ceiling perforation line that can meet customers' design requirements and aesthetic needs for perforated metal ceiling production.

|

|

|

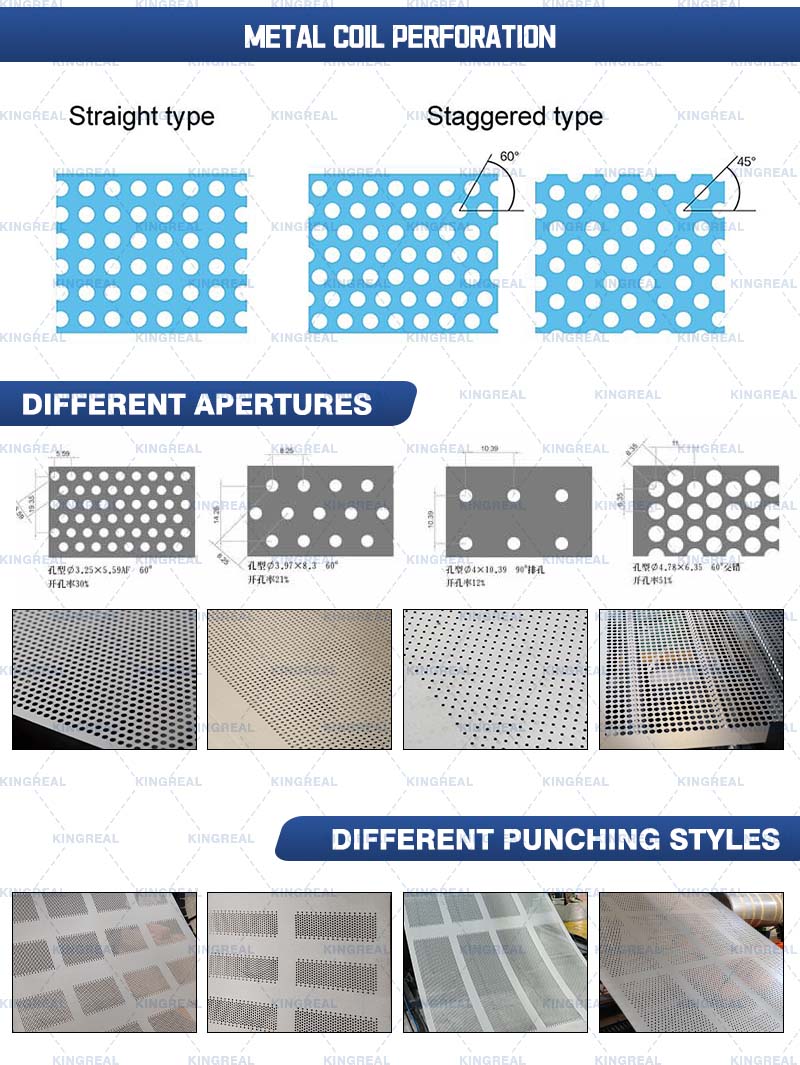

2. Customization of punching molds

In the punching process, the design and manufacture of the mold are crucial. BRUTE STEEL SLITTER can customize punching molds with different patterns and apertures according to the drawings provided by customers. Whether it is a standard design or a special requirement, BRUTE STEEL SLITTER's engineers can provide high-quality solutions to ensure that the products produced meet the customer's design standards.

|

|

|

3. Tonnage selection

The difference in the requirements for punching area and punching speed directly affects the tonnage of the required metal perforating machine. BRUTE STEEL SLITTER's engineers will analyze the production needs of the customer based on the actual situation of the customer and make appropriate tonnage recommendations. Such tonnage selection can ensure that customers get the best efficiency in the production process.

|

|

|