In the global manufacturing industry, steel coil slitting lines, as an important production equipment, are widely used in metal processing, automobile manufacturing, building materials and other fields.

With the development of the economy and the acceleration of the industrialization process, the demand for the steel coil slitting machine market is also growing. However, the competition in the market is becoming increasingly fierce, forcing major manufacturers to find their own competitive advantages in order to gain a foothold in this field.

According to market research reports, the scale of the steel coil slitting line machine market has continued to rise in the past few years and is expected to maintain steady growth in the next five years. There are many companies competing in the market, including some large equipment manufacturers and small and medium-sized enterprises. These companies each have different advantages and market positioning, forming a complex competitive ecology.

At present, the main competitive factors in the steel coil slitting machine market include price, technical level, product quality, after-sales service, etc. Price competition may attract some customers in the short term, but in the long run, technological innovation and service quality are the key to gaining customer trust and loyalty.

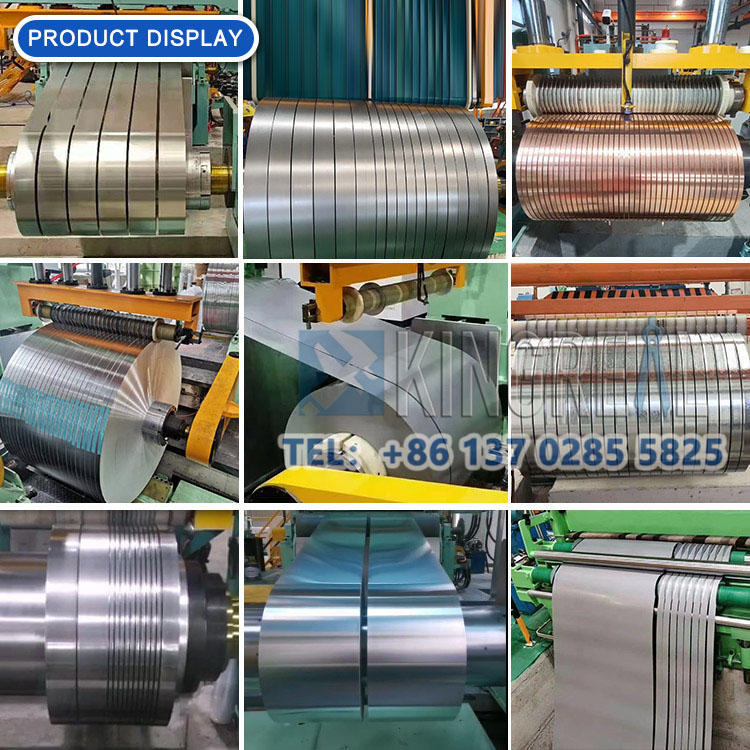

Steel coil slitting lines on the market generally have the following features:

1. Versatility: Modern steel coil slitting machines can not only perform traditional metal slitting operations, but also realize a variety of processing functions, such as punching and forming. This versatility greatly improves the efficiency of steel coil slitting line machines on production lines.

2. High degree of automation: With the rise of intelligent manufacturing, many manufacturers have introduced automation technology on steel coil slitter, making the operation of equipment simpler and more efficient, reducing dependence on manual labor.

3. High precision and high efficiency: Customers have higher and higher requirements for the precision and efficiency of steel coil slitting lines. Modern steel coil slitting line machines use advanced technology in the design and manufacturing process to improve the stability and cutting accuracy of the whole machine.

4. Environmental protection and energy saving: Against the background of increasingly stringent global environmental protection requirements, the design of steel coil slitter has also paid more and more attention to energy saving and environmental protection performance, and many manufacturers have begun to adopt more environmentally friendly materials and production processes.

5. Customized services: With the diversification of customer needs, more and more manufacturers provide customized services and can provide tailor-made steel coil slitting machine solutions according to the actual needs of customers.

In a highly competitive market environment, BRUTE STEEL SLITTER has successfully occupied a place in the steel coil slitting machine market with its unique differentiation strategy. The following are several major differentiation strategies of BRUTE STEEL SLITTER:

1. Technological innovation

BRUTE STEEL SLITTER has continuously invested in technological innovation and launched a number of steel coil slitting machine products with excellent performance, such as:

- Steel coil slitter with lamination:

When traditional steel coil slitting lines process metal coils, scratches and other damages on the surface of the material are often unavoidable. This not only affects the beauty of the metal material, but is also likely to affect subsequent processing and use. Therefore, BRUTE STEEL SLITTER introduced a laminating device in the design of the steel coil slitting line. Before the metal sheet is fed into the steel coil slitting line machine, the device first coats the metal surface with a thin film through an automated system. This film can effectively prevent scratches, dirt and other external factors from invading the metal surface. Customers can reduce additional processing work caused by surface damage in subsequent metal processing. This means that customers no longer need to spend extra time and money to repair surface scratches, thereby improving overall production efficiency.

- Steel coil slitter with protective shield

In industrial production, the safety of equipment is a key factor in ensuring the health of workers and improving production efficiency. To this end, BRUTE STEEL SLITTER has launched a steel coil slitter with a protective shield. This equipment is designed with full consideration of operational safety and strives to provide customers with a safer working environment. The protective cover is made of high-strength materials, which can effectively prevent metal coils from splashing or accidentally falling off during cutting, thereby avoiding harm to operators. Even under high load and high speed working conditions, the cover can remain stable and ensure safety.

In addition, in the design of the cover, BRUTE STEEL SLITTER also considers the convenience of operators. The opening and closing design of the cover makes it easy for operators to enter and exit the work area when performing equipment maintenance and adjustments without affecting safety protection.

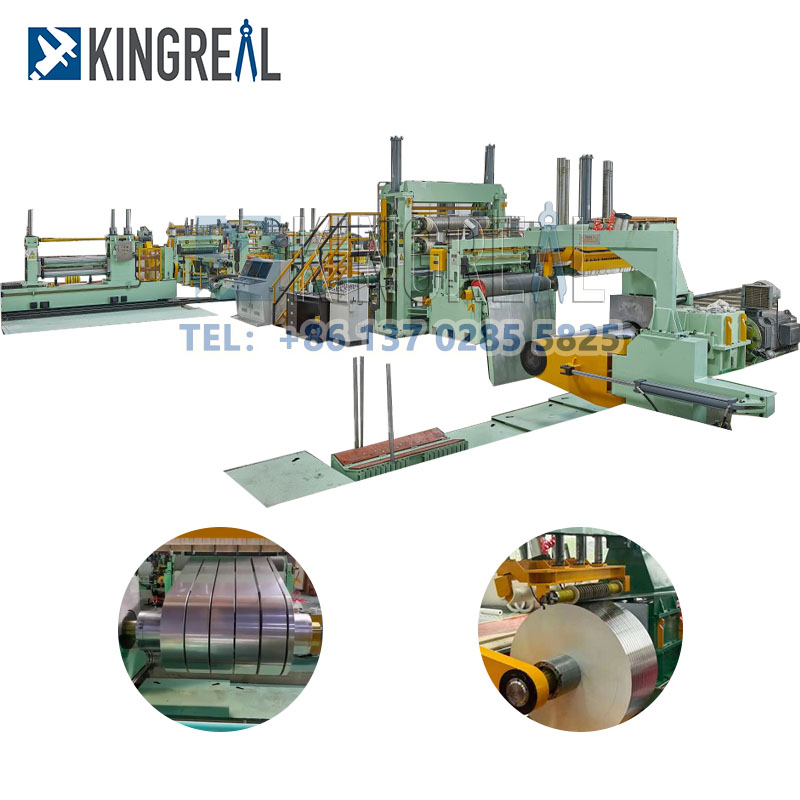

- Dual-slitter head steel coil slitting machine

In modern manufacturing, production efficiency is one of the important factors to improve competitiveness. In order to meet the market demand for efficient production, BRUTE STEEL SLITTER launched a dual-slitter head steel coil slitting line, which significantly improves work efficiency through innovative design and has become the first choice for many companies.

The core advantage of the dual-slitter head steel coil slitting machine lies in its unique knife seat design, which enables the equipment to be equipped with two knives at the same time during the production process. This design brings several significant efficiency improvements. By using two knives at the same time, the dual-slitter head steel coil slitting machine can process more metal coils at the same time. This means that the overall production capacity of the production line has been greatly improved, and the company can meet market demand at a faster rate.

2. Quality control

BRUTE STEEL SLITTER has strict standards and processes for product quality control. The company is very cautious in the selection of raw materials to ensure that each material meets the quality standards. During the production process, BRUTE STEEL SLITTER has developed a complete set of work processes, from design, manufacturing to trial operation, each step is strictly controlled to ensure that the quality of the final product meets customer expectations.

|

|

|

This strict control of quality not only improves customer satisfaction, but also enhances the brand's market competitiveness. When choosing a steel coil slitter, customers tend to prefer brands that can provide high-quality products.

3. Customized solutions

BRUTE STEEL SLITTER knows that the needs of each customer are different, so it provides flexible customized services. Customers can choose the material, thickness, number of strips and strip speed of metal raw materials according to actual production needs, and tailor a steel coil slitter that suits them.

|

|

|

This customized service not only improves customers' production efficiency, but also enhances customers' dependence and loyalty to the BRUTE STEEL SLITTER brand. In the process of communicating with customers, BRUTE STEEL SLITTER's sales team will understand customers' needs in detail, provide professional advice and solutions, and help customers optimize their production processes.

4. High-quality after-sales service

After-sales service is an important factor affecting customer satisfaction. BRUTE STEEL SLITTER performs well in after-sales service and provides comprehensive support. The engineer team is able to go to the customer's factory to install the equipment and provide detailed machine operation training for the workers. In this way, customers can quickly get started with the equipment and reduce losses caused by improper operation.

In addition, BRUTE STEEL SLITTER will inform customers in advance of the problems that are easy to encounter in machine operation and provide corresponding solutions. This proactive service not only enhances customers' trust, but also further enhances the brand image.