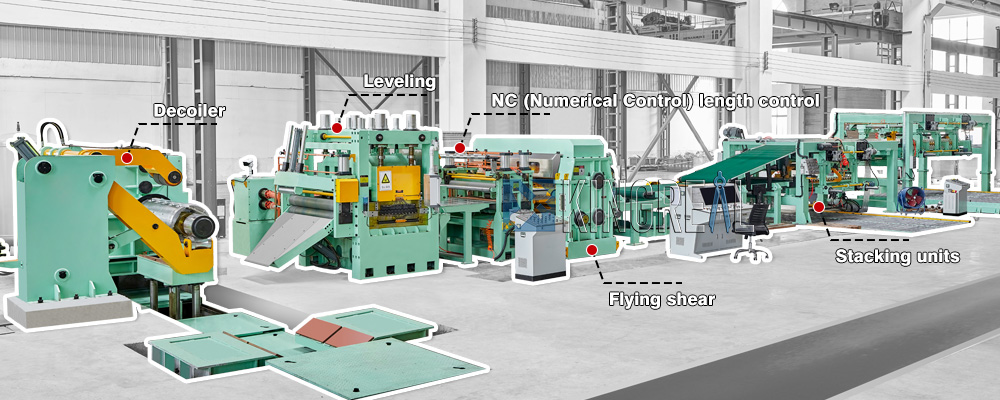

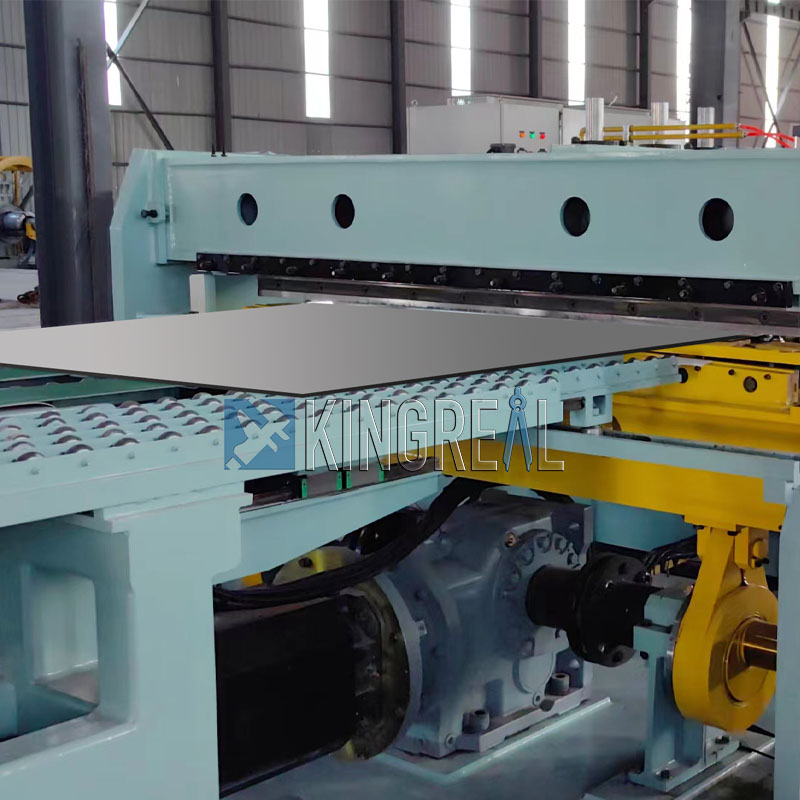

High speed cut to length line is a kind of mechanical equipment specially used for shearing metal materials, which is widely used in metal processing, construction, automobile manufacturing and other industries. Its main function is to shear large-sized metal plates into the required size for subsequent processing and use. The work flow of the high speed cut to length machine usually includes unwinding, leveling, cutting, and collecting.

With the acceleration of industrialization, the demand for high speed cut to length line machines in the market continues to increase, and its importance is becoming increasingly prominent.

The market prospects of high speed cut to length lines are quite broad, which is mainly reflected in the following aspects:

1. Multiple application fields

High speed cut to length machines can be widely used in multiple industries such as automobiles, ships, machinery manufacturing, and construction. With the continuous development of these industries, the demand for metal materials is increasing, which in turn promotes the market demand for high speed cut to length line machine. For example, in the automobile manufacturing industry, high speed cut to length machines can efficiently and accurately provide the required metal parts to ensure the smooth operation of the production line.

2. Subsequent processing and production needs

The metal sheets sheared by the high speed cut to length line machine can be used for subsequent processing and production, such as bending, welding, spraying, etc. Metal materials processed by high speed cut to length line machines can reduce the difficulty of subsequent processing and improve production efficiency. This convenience makes high speed cut to length machines occupy an important position in the metal processing industry and further promotes the growth of the market.

|

|

3. Driven by technological innovation

With the rapid development of science and technology, the technology of high speed cut to length line machines is also constantly innovating. Intelligent and automated high speed cut to length machines have gradually become the mainstream of the market, improving production efficiency and reducing labor costs. This technological progress provides more possibilities for enterprises and attracts a lot of investment to enter the high speed cut to length line machine market.

4. Trend of environmental protection and resource conservation

Globally, the awareness of environmental protection and resource conservation has gradually increased, and the design and production of high speed cut to length machines have also developed in a more environmentally friendly direction. High-efficiency, energy-saving and low-emission high speed cut to length line machine will become the darling of the market, and enterprises will pay more attention to its environmental performance when choosing equipment. This trend also brings new development opportunities to the high speed cut to length machine market.

With the diversification of market demand, customers' requirements for high speed cut to length line machines are also constantly improving. The high speed cut to length machine required by the modern market must not only have basic shearing functions, but also innovate the configuration of the high speed cut to length line machine according to the actual production requirements of customers. BRUTE STEEL SLITTER can do this well:

1. Customized manufacturing solution

BRUTE STEEL SLITTER's high speed cut to length line can provide customized machine manufacturing solutions according to the actual production needs and drawings of customers. Customers can choose the most suitable high speed cut to length line machine configuration according to their own production process and product requirements to ensure the efficiency and flexibility of production. Among them, the high speed cut to length line machine equipped with double stacking tables, the high speed cut to length line machine with laminating device and the high speed cut to length line machine equipped with double leveling machine are customized machines widely praised by customers.

High speed cut to length line machine with double stacking table: In order to improve production efficiency, BRUTE STEEL SLITTER provides high speed cut to length machines with double stacking tables. This design can greatly improve the continuity and efficiency of the production line.

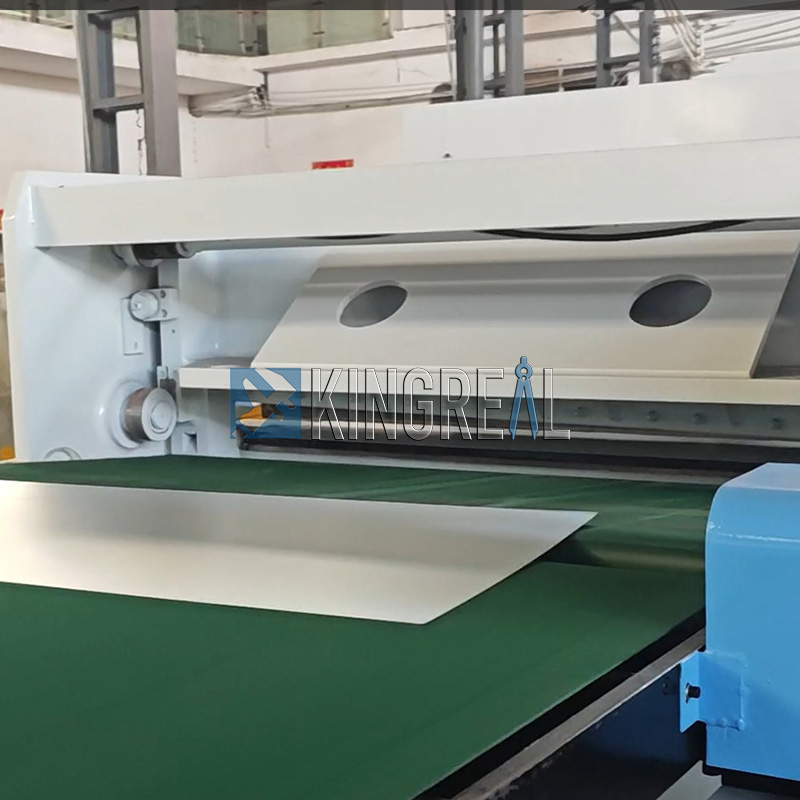

High speed cut to length line machine with laminating device: In the processing of metal materials, in order to protect the surface, BRUTE STEEL SLITTER's high speed cut to length line machine is equipped with a laminating device to complete the laminating before the metal sheet is sheared, meeting the market's demand for metal surface protection.

High speed cut to length line machine with double leveler: In order to ensure the flatness of the metal sheet after shearing, BRUTE STEEL SLITTER's high speed cut to length line machine is equipped with a double leveler, that is, the metal sheet must undergo two leveling processes before being sheared. This design not only improves the quality of the finished product, but also reduces problems in subsequent processing and ensures the smooth progress of production.

|

|

|

2. Different metal materials

The market has different demands for different metal materials. BRUTE STEEL SLITTER's high speed cut to length machine has launched different high speed cut to length line machines for different metal materials, including steel high speed cut to length line machines, copper high speed cut to length line machines, hot-rolled high speed cut to length line machines, cold-rolled high speed cut to length line machines, etc. BRUTE STEEL SLITTER can provide efficient solutions to meet the needs of different customers.

|

|

|