In the metal processing industry, heavy gauge cut to length machines play a pivotal role in transforming large metal coils into precisely cut sheets. These machines operate through a series of processes that ensure the final product meets specific quality and dimensional requirements. This article explores what a heavy gauge cut to length line machine is, its working process, and important operational considerations.

Heavy gauge cut to length machine is a device used to cut metal coils into required lengths. This equipment is usually used to process thicker metal materials such as steel, aluminum and stainless steel. Through a series of process steps, including uncoiling, leveling and shearing, the heavy gauge cut to length machine can efficiently meet customers' needs for metal sheets.

1.1 Function and application

The main function of the heavy gauge cut to length line machine is to process metal coils into metal plates of specific sizes. This equipment is widely used in multiple industrial fields, such as construction, automobiles, home appliances and machinery manufacturing. In these fields, accurate metal cutting is essential for subsequent manufacturing and assembly processes. By using a heavy gauge cut to length line, companies can effectively transform metal materials into finished products that can be used for production, reducing labor costs and material waste.

1.2 Equipment composition

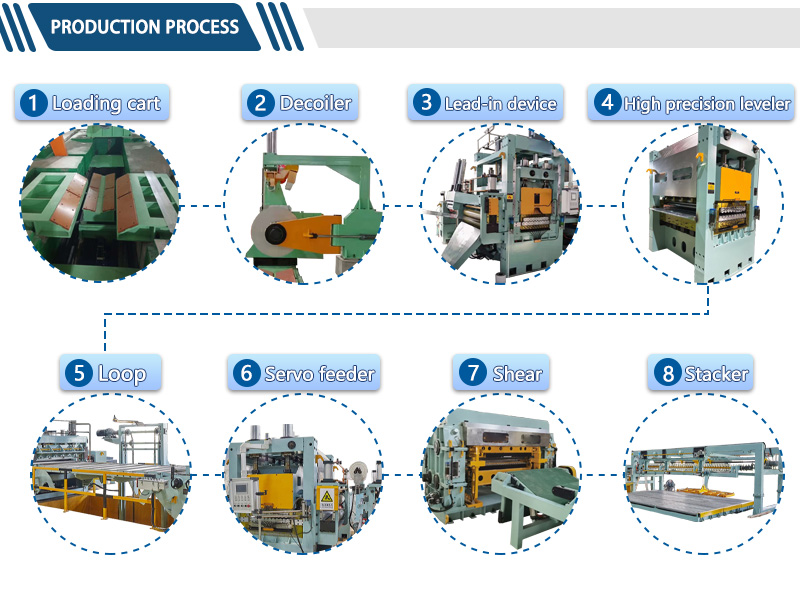

A heavy gauge cut to length line machine usually consists of multiple key components, including decoilers, leveling machines, cut to length machines, waste collection devices, conveyor belts and stacking machines. Each part plays an indispensable role in the workflow of the heavy gauge cut to length line machine to ensure the smooth progress of the entire process.

1.3 Market demand

With the continuous development of the global manufacturing industry, the market demand for metal sheets is gradually increasing. The demand for efficient and precise metal processing equipment has also risen. Shearing lines have become the first choice for many companies due to their high efficiency and reliability. This heavy gauge cut to length machine not only improves production efficiency, but also ensures the quality of finished products and meets the diverse needs of customers.

The workflow of heavy gauge cut to length line machines is usually divided into several main steps: unwinding, leveling, shearing, scrap collection and stacking. The function and importance of each step will be described in detail below.

2.1 Decoiler

The decoiler is the first step of the heavy gauge cut to length machine. Its main function is to unwind the metal coil from the reel. A high-quality decoiler can ensure that the material enters the subsequent steps smoothly and avoids material damage caused by uneven coil tension. Decoilers are usually equipped with tension control devices to ensure that the material maintains proper tension during the unwinding process.

During operation, staff need to regularly check the status of the coil to ensure that it has no obvious defects or damage. In addition, the maintenance of the decoiler is also crucial. Regular cleaning and lubrication can extend its service life.

2.2 Leveler

The function of the leveler is to level the metal material after unwinding. This step is crucial to ensure the accuracy of the subsequent shearing process. The leveler applies uniform pressure to the metal material through devices such as pressure rollers to remove deformation caused by curling or bending.

The leveler is usually adjusted according to the thickness and hardness of the material to ensure the best leveling effect. The operator needs to pay attention to the operating status of the leveler and regularly check the wear of the rollers to ensure that it is always in the best working condition.

2.3 Cut to Length Machine

The cut to length machine is the core part of the heavy gauge cut to length line and is responsible for cutting the leveled metal material according to the length required by the customer. The design of the heavy gauge cut to length line usually adopts high-strength knives to ensure that it has sufficient cutting capacity when processing thick metal materials.

During the shearing process, the operator needs to set the length and quantity of the shearing and monitor the operating status of the equipment. An efficient heavy gauge cut to length line machine can complete a large number of cutting tasks in a short time and improve production efficiency.

2.4 Waste Collection Device

During the shearing process, some waste is often generated. The function of the waste collection device is to effectively collect these wastes and ensure a clean working environment. Timely disposal of waste not only helps to improve work efficiency, but also reduces the occurrence of accidents.

Modern heavy gauge cut to length machines are usually equipped with advanced waste collection systems that can automatically transport waste to designated locations and reduce manual intervention. Operators need to regularly check the status of the waste collection device during use to ensure its normal operation.

2.5 Conveyor belt and stacker

The conveyor belt is responsible for conveying the sheared metal sheets to the next process or finished product area. The design of the conveyor belt should ensure that the material is not damaged during transportation and can accommodate metal sheets of different sizes and weights.

The stacker is responsible for stacking the cut metal sheets neatly for subsequent packaging and transportation. The efficient operation of the stacker can save a lot of labor costs for the company and improve work efficiency.

There are several key considerations when using the heavy gauge cut to length line to help ensure the safe and efficient operation of the equipment.

3.1 Correct operation

Correct operation is the basis for ensuring the efficient operation of the heavy gauge cut to length line machine. Operators should be professionally trained to understand the various parts of the equipment and their functions. During operation, the instructions in the operating manual should be strictly followed to ensure that each step is carried out in accordance with the standard process.

In addition, operators are required to conduct regular safety checks to ensure that all safety protection devices are intact. Especially when commissioning and maintaining the equipment, be sure to cut off the power supply to prevent accidents.

3.2 Regular inspection and maintenance

Regular inspection and maintenance of the heavy gauge cut to length machine is the key to ensuring the normal operation of the equipment. Operators need to regularly check the wear of each component to ensure that components such as decoilers, levelers, shears, waste collection devices and conveyor belts are always in the best condition.

During the inspection process, special attention should be paid to the sharpness of the tool. If the tool is severely worn, it will directly affect the accuracy and efficiency of the shearing, and may even cause equipment failure. Therefore, the tool should be replaced regularly according to the usage.

3.3 Fault handling and emergency measures

In the process of using the heavy gauge cut to length machine, it is inevitable to encounter some faults. Operators should have certain troubleshooting capabilities and be able to quickly identify the problem. Common faults include equipment shutdown, uneven cutting, and material jamming.

For different faults, operators should take corresponding emergency measures. For example, when the equipment is shut down, the power supply and control system should be checked first to ensure their normal operation. If the material is stuck, the power supply should be cut off and the material should be cleaned carefully under the premise of ensuring safety.

|

|

|