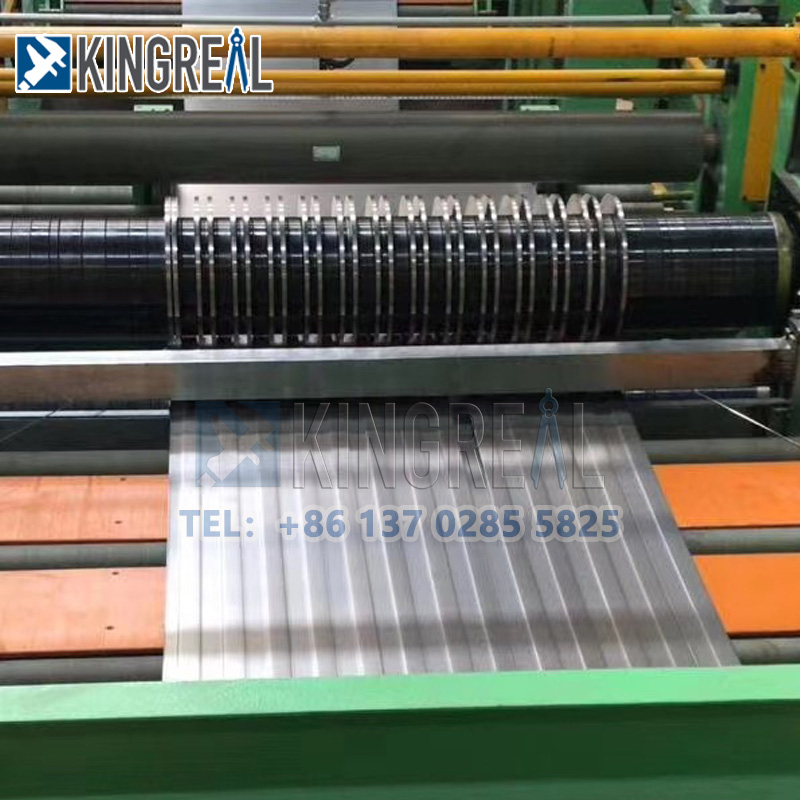

In modern industrial production, light gauge coil slitter are an indispensable equipment widely used in the metal processing industry. Its main function is to split metal sheets into narrow strips that meet the production needs of customers. These narrow strips can be used for further processing or directly used to produce finished products.

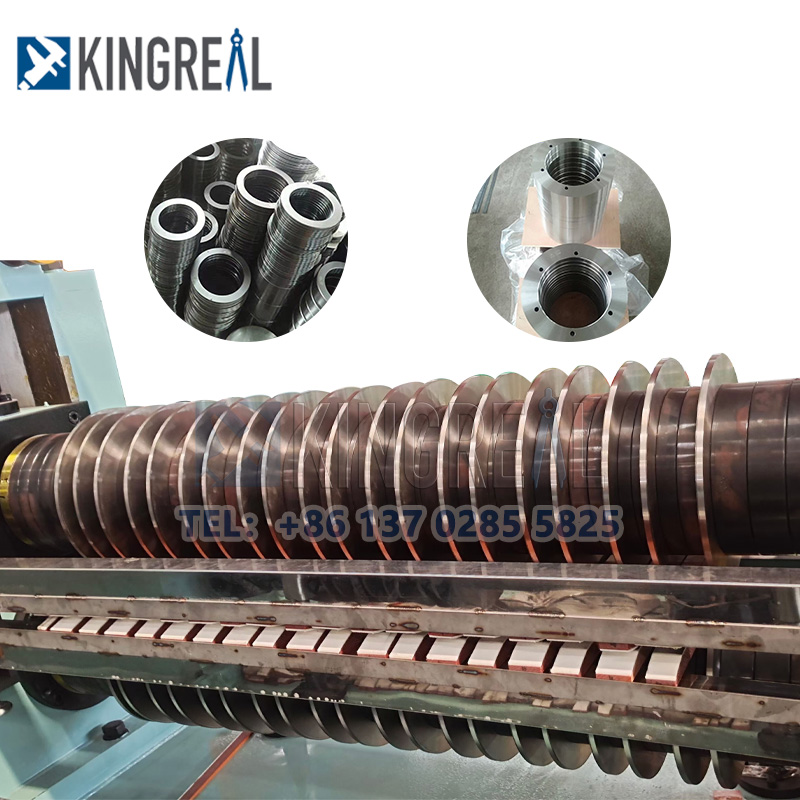

In the operation of the light gauge coil slitting machine, the blade, as its core component, plays a vital role. The quality of the blade directly determines the effect, speed and quality of the finished product of the slitting. Therefore, understanding the possible failures of the blade and its solutions is of great significance to improving production efficiency and reducing costs.

The working principle of the light gauge coil slitting line is relatively simple, but its structure and technical requirements are quite complex. The light gauge coil slitting machine feeds large-format metal sheets into the blade and uses the sharp cutting of the blade to split it into strips of material of the required width. This process requires not only high hardness and wear resistance of the blade, but also precise control of parameters such as the installation position and cutting angle of the blade. Therefore, the importance of the blade in the light gauge coil slitter is self-evident.

The quality and performance of the blade directly affect the service life of the tool, the accuracy of the slitting and the production efficiency. Severe wear or failure of the blade will not only lead to a decline in the quality of slitting, but may also cause failure of the entire machine, thereby increasing production costs. Therefore, timely understanding of common blade failures, analyzing the causes of failures, and taking effective solutions are skills that every light gauge coil slitting line operator and maintenance personnel must master.

|

|

|

During the use of the light gauge coil slitting machine, the blade often has the following failures:

1. Wear

Blade wear is one of the most common failures in the use of light gauge coil slitting line blades. With the long-term use of the light gauge coil slitting machine, the friction between the blade and the material during the cutting process will cause its sharpness to decrease, thereby affecting the cutting effect. When the wear is severe, the blade may not be able to cut the material smoothly, and may even cause uneven cutting or burrs.

2. Notch

Blade notch is a failure that is prone to occur when the blade is impacted by external force or when cutting hard materials. When a part of the blade has a notch, the cutting effect will be significantly affected, which may cause uneven material slitting or generate more waste. In addition, the notch may also cause further damage to the blade and increase the frequency of blade replacement.

3. Improper installation

The installation position and angle of the blade have an important impact on the cutting quality. If the blade is not installed properly, it may cause uneven pressure during the cutting process, which will affect the cutting effect and service life of the blade. Improper installation may also cause the blade to shift during operation, or even cause equipment failure.

4. Material mismatch

The degree of match between the blade and the material being cut directly affects the cutting effect. If the hardness or material of the blade does not match the metal sheet being cut, it may cause premature wear or damage to the blade. In addition, factors such as material thickness, hardness and toughness will also affect the use of the blade.

|

|

|

The reasons for blade failure are varied, mainly including the following:

1. Improper operation

The operating habits and skill level of the operator directly affect the use of the blade. Improper operating methods, such as too fast feed speed, wrong cutting angle, etc., will accelerate the wear of the blade. In addition, the operator's lack of attention to the maintenance and adjustment of the equipment may also cause blade failure.

2. Material quality

The quality of the material being cut is directly related to the service life of the blade. If the material has problems such as uneven hardness, excessive impurities or rough surface, the wear of the blade will increase and even cause damage to the blade. Therefore, choosing high-quality materials is the basis for ensuring the normal operation of the blade.

3. Insufficient maintenance

Maintenance and care of the light gauge coil slitting machine are the key to ensuring the normal operation of the blade. If the equipment is not maintained for a long time, it is easy to cause the wear of the blade to increase. In addition, maintenance work such as cleaning and lubrication of the blade must also be carried out regularly to avoid the accumulation of impurities on the blade affecting the cutting effect.

4. Environmental factors

The working environment of the light gauge coil slitting line will also affect the use effect of the blade. For example, a humid environment may cause the blade to rust, while a high-dust environment may cause dirt to accumulate on the surface of the blade and increase wear. Therefore, maintaining a good working environment is an important measure to extend the service life of the blade.

|

|

|

For various faults of the blade, taking effective solutions is the key to ensuring the normal operation of the light gauge coil slitting line.

1. Regular inspection and maintenance

Regular inspection and maintenance of the blade can effectively reduce the possibility of failure. When checking, focus on the wear, notch and installation position of the blade. Through regular cleaning and lubrication, the wear of the blade can be reduced and its service life can be extended.

1.1 Check the wear

Check the wear of the blade regularly and replace the blade in time if it is severely worn. You can use professional measuring tools (such as thickness gauges) to test the thickness of the blade to determine whether it meets the use standards.

1.2 Clean the blade

After each production, the blade should be cleaned to remove metal chips and dirt attached to the blade. You can use special cleaning agents and brushes to clean it to ensure that the blade is in good cutting condition.

2. Replace the blade

When the blade wear reaches a certain degree or there is a clear gap, the blade should be replaced immediately. When replacing the blade, make sure that the quality of the new blade meets the standard and install it correctly according to the requirements of the equipment.

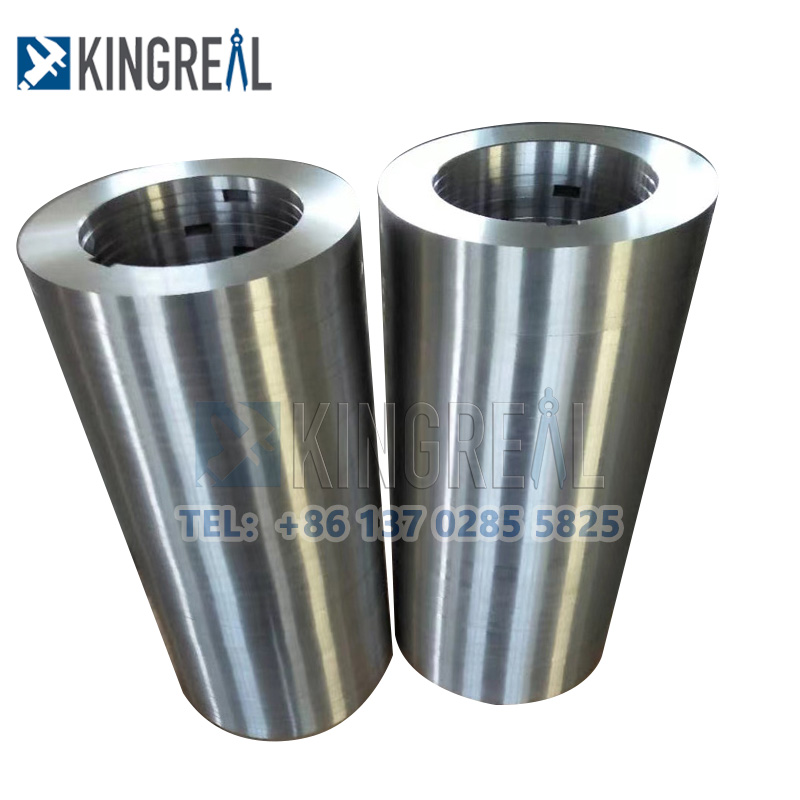

2.1 Blade selection

Select the appropriate blade material and hardness, and select the appropriate blade type according to the characteristics of the material being cut. Generally speaking, for materials with higher hardness, it is recommended to use blades with high hardness and high wear resistance.

2.2 Installation precautions

When replacing the blade, ensure that the installation position and angle of the blade are accurate. Professional tools can be used for auxiliary installation to ensure that the blade is stable during the operation of the equipment and will not shift.

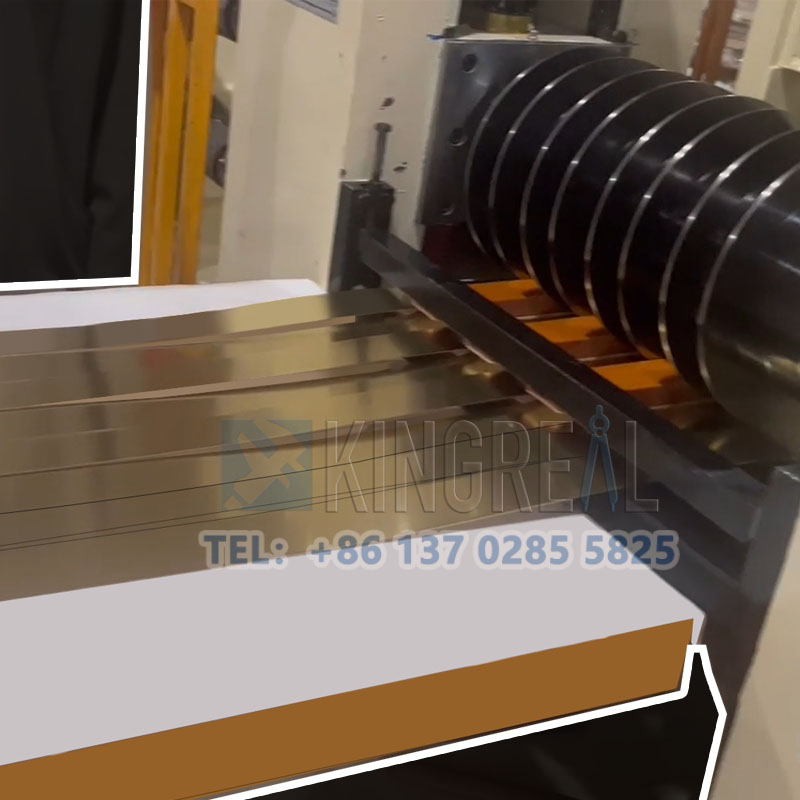

3. Adjust the blade

The installation angle and pressure of the blade should be adjusted according to the characteristics of the material being cut. Appropriate cutting angle and pressure can effectively improve cutting efficiency and reduce blade wear.

3.1 Adjust the cutting angle

According to the thickness and hardness of the material, adjust the cutting angle of the blade appropriately to ensure the best cutting effect. Generally speaking, thicker or harder materials require a larger cutting angle, while thinner or softer materials require a smaller cutting angle.

3.2 Adjust the feed speed

According to the cutting capacity of the blade and the characteristics of the material being cut, adjust the feed speed reasonably. Too fast a feed speed will increase the burden on the blade, causing increased wear and even damage to the blade. Therefore, the operator should make adjustments according to the actual situation.

|

|

|