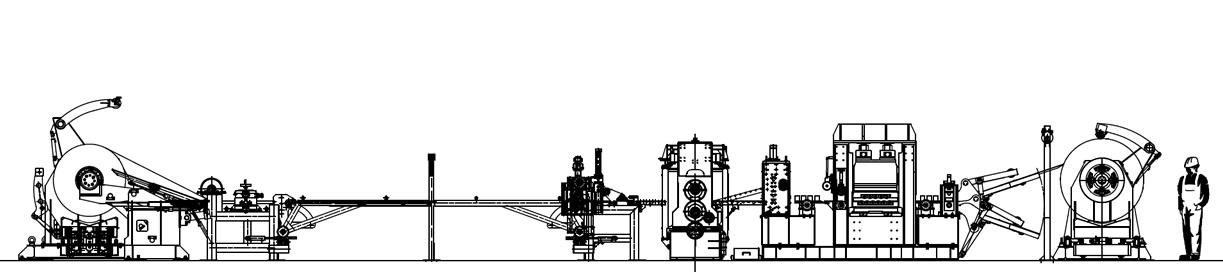

Light gauge cut to length machine is an efficient equipment for processing metal coils into required lengths. Through a series of operations such as uncoiling, leveling, and cutting, the shearing line can transform large coils of metal materials into metal sheets suitable for downstream processing or direct use. This equipment plays an important role in modern manufacturing and is widely used in multiple industries to meet the needs of different customers.

The main purpose of light gauge ctl line is to accurately shear metal coils to generate metal sheets of specific sizes. This process usually includes the following steps:

1. Uncoiling: Unroll the metal coil from the roll and prepare for subsequent processing.

2. Leveling: Through the leveling machine, the warping and deformation of the metal coil during the coiling process are eliminated to ensure the accuracy of subsequent shearing.

3. Cutting: Cut the metal material into specific sizes according to the length required by the customer.

The flexibility and efficiency of the light gauge cut to length machine enable it to play an important role in different manufacturing environments. It not only improves production efficiency, but also reduces labor costs. It is an indispensable equipment in modern production lines.

1. Market demand

The market demand for light gauge ctl lines is growing, especially in the following countries and regions:

- The United States: The demand for light gauge cut to length machines in the manufacturing, construction and automotive industries in the United States continues to rise, especially in high-precision and high-efficiency production environments.

- Germany: Germany is known for its high-standard manufacturing industry, and its requirements for light gauge ctl lines are relatively high, especially in the fields of automobile and machinery manufacturing.

- India: With the rapid development of India's manufacturing industry, the demand for light gauge cut to length lines has gradually increased, especially in construction and infrastructure construction.

2. Application areas

Light gauge cut to length machines are widely used in many fields, including:

- Automobile manufacturing: In the production of automobile parts, metal coils need to be cut into precise sizes to ensure the matching and assembly of parts.

- Construction and engineering: In the construction industry, light gauge cut to length lines are used to make steel structures and other building materials to ensure construction quality and efficiency.

- Home appliance manufacturing: The demand for metal casings and internal structural parts in the home appliance industry makes light gauge ctl lines an important equipment in this field.

- Aerospace: In the aerospace field, light gauge cut to length machines are used to process high-strength metal materials to meet strict safety standards.

- Electronic products: In the manufacture of electronic products, light gauge cut to length lines are used to make various metal shells and internal brackets to ensure the performance and appearance of the products.

|

|

Light gauge cut to length machines provide various types of equipment according to different needs and applications. These types are mainly reflected in the metal raw materials, coil thickness and shearing methods.

1. Different metal raw materials

Customers have different processing requirements for metal raw materials, so BRUTE STEEL SLITTER provides a variety of light gauge cut to length line manufacturing solutions to meet different processing requirements:

- Stainless steel light gauge cut to length machine: Stainless steel is widely used in construction and home appliances due to its excellent corrosion resistance and strength. Specially designed stainless steel light gauge ctl lines can ensure efficient shearing and good surface quality.

- Copper light gauge cut to length machine: Copper material is suitable for electrical and electronic products due to its excellent electrical and thermal conductivity. The ductility of the material should be considered when designing the copper light gauge ctl line to ensure the shearing effect.

- Hot-rolled light gauge cut to length machine: Hot-rolled coils are usually thicker and suitable for heavy industrial applications. Hot-rolled light gauge ctl lines can handle thicker metal materials to meet the needs of construction and manufacturing industries.

- Cold-rolled light gauge cut to length machine: Cold-rolled coils are generally thinner and suitable for industries with high precision requirements, such as home appliances and automobiles. Cold-rolled light gauge ctl lines can ensure high precision and good surface treatment.

|

|

|

2. Different coil thicknesses

According to the thickness of different metal coils, BRUTE STEEL SLITTER has produced three types of light gauge cut to length lines to meet different production needs:

- Light gauge ctl line: It can handle metal coils with a thickness of 0.3-3mm, suitable for light metal processing, and widely used in the electronics and home appliance industries.

- Medium gauge ctl line: It can handle metal coils with a thickness of 0.3-6mm, suitable for automobile and machinery manufacturing, providing good shearing accuracy and production efficiency.

-Heavy gauge ctl line: It can process metal coils with a thickness of 6-20mm, suitable for the processing of heavy structural parts, such as the construction and shipbuilding industries, and can meet the needs of high-strength and large-scale production.

3. Different shearing methods

BRUTE STEEL SLITTER provides light gauge cut to length lines with various shearing methods to meet the different production needs of customers:

- Flying shear light gauge cut to length machine: Shearing is performed by high-speed flying shears, which is suitable for rapid production and large-scale processing, ensuring high efficiency and high precision.

- Rotary shear light gauge ctl line: Rotary cutters are used for shearing to achieve uninterrupted shearing without stopping the material, thereby minimizing the indentation of the plate when the shearing is started.

- Fixed shear light gauge cut to length machine: The metal plate is stopped by the servo system at the moment of shearing, and then removed by the servo system after shearing. Due to the shutdown processing during shearing, the production efficiency is lower than other shearing types.