1.1 Definition of steel perforated machine

Metal perforated making machine, referred to as steel perforated machine, is a kind of equipment specially used to process metal coils into perforated metal plates. Its main work process includes unwinding, leveling, punching and other steps. Metal perforated making machine is widely used in many industries and can meet different production needs.

The use of perforated plates is very wide, mainly reflected in the following aspects:

√ Ventilation and heat dissipation

√ Decoration and beauty

√ Filtration and screening

√ Safety and protection

1.2 Workflow of steel perforated machine

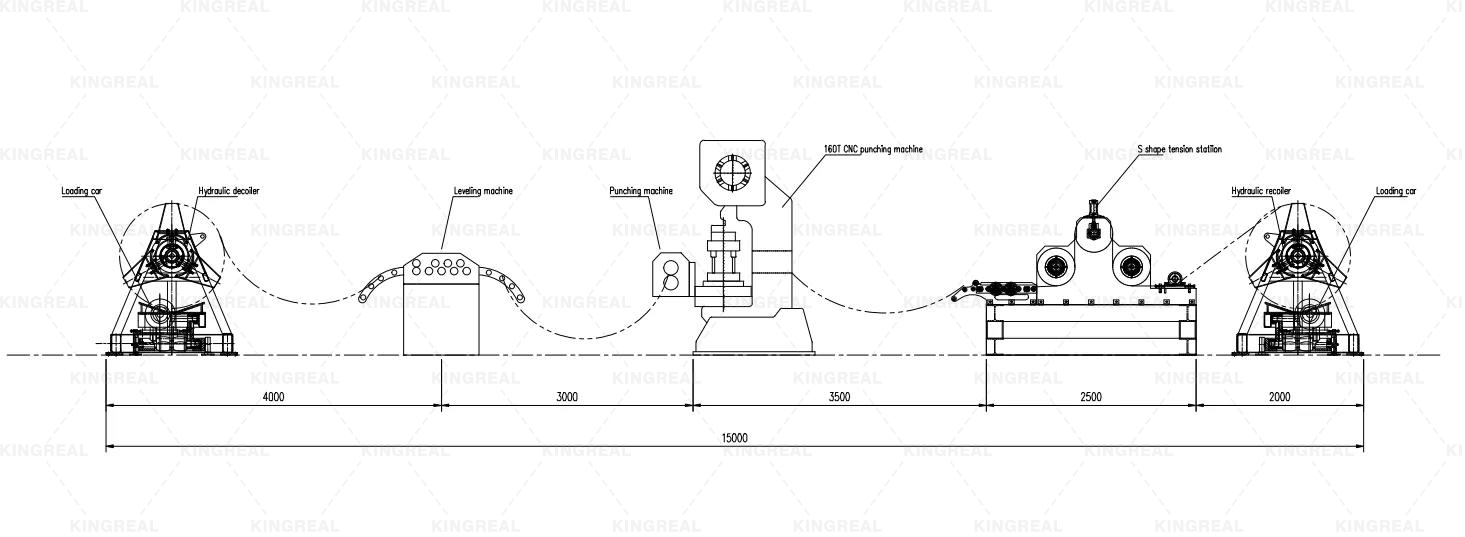

The work flow of metal sheet perforated machine is usually divided into the following steps:

1. Unwinding: Place the metal coil on the decoiler and control the tension to make the metal coil unfold smoothly.

2. Leveling: The unwinding metal coil may have certain waves or deformations, and the leveling machine will correct them to ensure the accuracy of subsequent punching.

3. Punching: Use the punching die to punch the flattened metal plate. According to different molds, holes of different types and diameters can be produced. Common hole types include round holes, square holes, slotted holes, etc.

4. Rolling or cutting: After punching, you can choose to roll the punched plate or cut it according to customer needs.

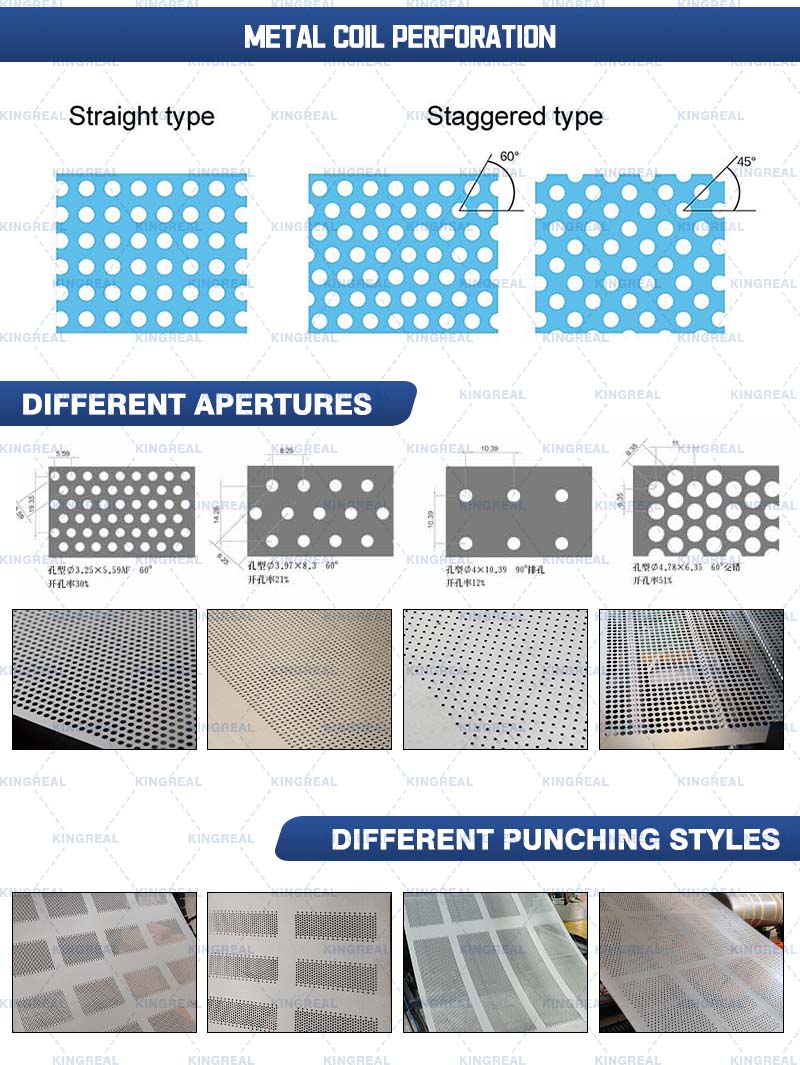

1.3 Common hole types

During the punching process, the type of mold used determines the hole type of the punched plate and its application. Common hole types include:

- Round hole: suitable for ventilation and drainage, commonly used in filters and heat sinks.

- Square hole: mostly used for architectural decoration and safety protection, providing good visual effects.

- Slotted hole: suitable for occasions where drainage and exhaust are required, and often used in ventilation equipment.

Through the design of these different hole types, the steel perforated machine can meet diverse market needs.

The emergence and development of the metal sheet perforated machine is of great significance. Traditional punching processes often rely on manual operation, which is inefficient and prone to errors. With the entry of fully automatic steel perforated machines into the market, production efficiency has been significantly improved.

The advantages of automated metal perforated making machines are reflected in the following aspects:

- Improve production efficiency: The fully automated steel perforated machine operation process greatly shortens the production cycle and can quickly meet the needs of mass production.

- Reduce labor costs: The automated metal perforated making machine reduces dependence on labor, reduces labor costs, and improves work safety.

- Improve product consistency: The precise control of the automated steel perforated machine ensures product consistency and reduces quality fluctuations caused by human factors.

- Flexible response: Modern metal perforated making machines can be flexibly adjusted according to market and customer needs, and support rapid switching of multiple different hole types.

These advantages make steel perforated machines play an indispensable role in the manufacturing industry and promote the progress of the entire industry.

|

|

|

The application areas of metal perforated making machines are very wide, covering almost all walks of life. After secondary processing, the perforated sheet can be used for different products and processes.

1. Building decoration

In the building decoration industry, perforated metal sheets are widely used. They can be used in places such as walls, ceilings and partitions, which can not only provide beautiful visual effects, but also meet the needs of ventilation and heat dissipation. The design diversity of perforated sheets enables architects and designers to create a variety of unique spatial effects.

2. Industry

In the industrial field, perforated sheets are often used to manufacture ventilation equipment, filters and protective covers. Punching technology can effectively improve the heat dissipation performance of steel perforated machine while ensuring safety.

3. Food processing

The food processing industry has extremely high requirements for hygiene and safety. The

metal perforated making machine can produce perforated sheets that meet food safety standards for screening, filtering and packaging.

4. Chemical and pharmaceutical

In the chemical and pharmaceutical industries, perforated sheets are widely used in steel perforated machine such as reactors and separators. Its good permeability and strength meet the requirements of chemical reactions and material separation.

5. Environmental protection energy

The environmental protection energy industry also uses a large number of perforated sheets, especially in solar and wind energy equipment. For example, solar panel brackets and protective covers of wind power generation equipment can all use punching technology to enhance their structural strength and safety.

Through the display of these application fields, we can see the importance and wide application of metal perforated making machines in modern industrial production.

According to different application scenarios, BRUTE STEEL SLITTER divides steel perforated machines into the following three types:

|

Steel perforated machine with cutting

BRUTE STEEL SLITTER is equipped with a cutting station for the steel perforated machine. After the punching is completed, the cutting station automatically cuts according to the length set by the customer. This type of metal perforated making machine is suitable for making wall panels, chairs, balcony guardrails, screens, stairs, separators, filter devices and other products. |

|

Steel perforated machine with rewinding

BRUTE STEEL SLITTER is equipped with a recoiler for the metal perforated making machine. After the punching is completed, the recoiler will wind up the perforated sheet. This method is convenient for storage and subsequent processing, and is suitable for making baffle ceilings, ventilation and heat dissipation panels, filters, screens, washing baskets, grills, wind power equipment protective covers, solar panel brackets, etc. |

|

Metal ceiling perforation line

BRUTE STEEL SLITTER's metal ceiling perforation line can be used with the metal ceiling machine to produce different types and sizes of perforated ceilings. For example, the sizes may include 30x30cm, 30x60cm, 30x120cm, 60x60cm, 60x120cm, etc., suitable for various types of ceilings such as clip in, lay in, tegular, etc.

Through such classification, customers can choose the appropriate steel perforated machine according to their needs to improve production efficiency and product quality. |