Fly shear cut to length machines are indispensable equipment in the modern metal processing industry, and there are many types to meet the needs of different customers. As a fly shear ctl line manufacturer with more than 20 years of rich experience, BRUTE STEEL SLITTER is committed to providing customers with one-stop fly shear cut to length line services. BRUTE STEEL SLITTER not only involves R&D, design, sales and production, but also provides comprehensive after-sales services to ensure that customers can get timely support and help during use.

According to the different production needs of customers, BRUTE STEEL SLITTER engineers have designed various types of fly shear ctl lines. These metal cut to length machines include but are not limited to fly shear ctl lines, fixed shear cut to length machines, swing shear cut to length lines, metal cut to length machine with lamination, light gauge cut to length machines, medium gauge cut to length machines and heavy gauge cut to length machines. Each type of fly shear cut to length line has its unique application scenarios and advantages, which can meet the needs of different markets and industries.

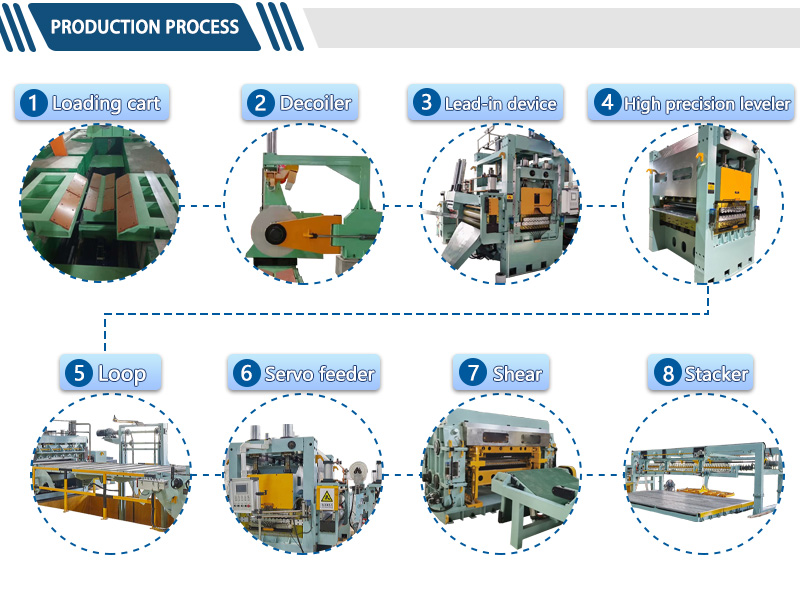

The structure of fly shear cut to length machines is relatively complex, mainly composed of multiple precision components to ensure its efficient and stable operation. The following are the main components of the fly shear ctl line:

- Decoiler: used to unwind the metal coils for subsequent processing.

- Leveling machine: Level the unrolled metal sheets to eliminate the waves and depressions generated during the coiling process and ensure shearing accuracy.

- Cut to length machine: It is the core component of the fly shear cut to length machine and is responsible for shearing the metal sheets into the required size.

- Waste collection device: used to collect waste generated during the shearing process to keep the working environment clean.

- Conveyor belt: Automatically transport the sheared metal sheets to the next process to improve production efficiency.

- Stacker: Stack the sheared metal sheets for subsequent storage and transportation.

The coordinated work of these components enables the fly shear cut to length machine to achieve efficient and automated production.

The fly shear ctl line is an advanced type of fly shear cut to length machine, which is characterized by high-speed shearing without stopping during the shearing process. This fly shear cut to length line is particularly suitable for large-scale production occasions, and can ensure shearing quality while maintaining high efficiency.

The core of the fly shear cut to length machine lies in its flying shearing mode, which can keep the fly shear ctl line running continuously when shearing metal sheets. Compared with the traditional fixed shear cut to length line, the fly shear cut to length machine does not need to stop during the shearing process, so it greatly improves production efficiency and reduces the time waste caused by downtime.

Fly shear ctl lines are mainly for customers with large production scales and extremely high requirements for production efficiency. These customers are usually in fierce market competition, and time is money. Therefore, they need to shear as many metal sheets as possible within the specified time to meet market demand.

For larger factories, investing in fly shear cut to length machines is a wise choice. BRUTE STEEL SLITTER's fly shear ctl line can not only quickly shear metal sheets, but also has a high return on investment. Through reasonable investment, these factories can recover their costs within a period of time and then make a profit.

5.1 Fast Speed

BRUTE STEEL SLITTER's fly shear ctl line has an extremely high shearing speed, up to 80 m/min. This speed can fully meet the production needs of customers and make large-scale production possible. In a highly competitive market, speed advantage often determines the market share of enterprises.

5.2 No Stoppage

Another significant advantage of the fly shear cut to length machine is that it does not stop when shearing metal sheets. This design not only improves production efficiency, but also maintains the continuity of the production process. Compared with traditional fixed shear cut to length lines, fly shear ctl lines can achieve efficient shearing without affecting production, greatly improving work efficiency.

5.3 Fully Automatic

BRUTE STEEL SLITTER's fly shear cut to length machine consists of fully automated components, which greatly improves its automation level. This fully automated design not only reduces the dependence on human resources, but also significantly reduces labor costs and time costs. The advantage of the automated fly shear ctl line is that the machine can maintain a stable working speed, avoiding fatigue and errors caused by manual operation, and ensuring the stability and consistency of the production process.

|

|

|

Fly shear cut to length machines are widely used in many industries, especially in areas with high requirements for production efficiency and shearing quality. The following are some of the main application areas:

6.1 Automobile manufacturing

In the automobile manufacturing industry, metal sheets are used in the production of parts such as body and chassis. The fly shear ctl line can quickly and efficiently shear the required metal sheets to meet the high demand for materials in the automobile production process.

6.2 Aerospace

The aerospace industry has extremely strict requirements for metal materials. The high-precision shearing of the fly shear cut to length machine can ensure the quality of the materials and meet the needs of aircraft component production.

6.3 Home appliance manufacturing

In the home appliance manufacturing industry, the fly shear ctl line can efficiently shear metal sheets and provide raw materials for the housing and internal structure of home appliances. Its efficient production capacity can meet the needs of large-scale production.

6.4 Construction Industry

The construction industry often requires a large amount of metal plates for structure and decoration. The application of fly shear cut to length machines can effectively improve the production efficiency of materials and speed up the progress of the project.