Stainless steel cut to length line is an indispensable and important equipment in the modern metal processing industry. It is mainly used to cut metal coils to the length expected by customers. Through a series of process flows, the stainless steel cut to length machine can unwind, flatten and shear large coils of metal materials into the required specifications, laying a good foundation for subsequent secondary processing and manufacturing.

With the continuous acceleration of the industrialization process and the increasing market demand for metal processing, the use of ss cut to length line machines is particularly important, especially when dealing with high-strength materials such as stainless steel. Its advantages are more obvious.

The main function of stainless steel cut to length machines is to unwind, flatten and shear metal coils to meet the needs of different customers. Specifically, the use of stainless steel cut to length lines can be summarized as follows:

1.1 Unwinding

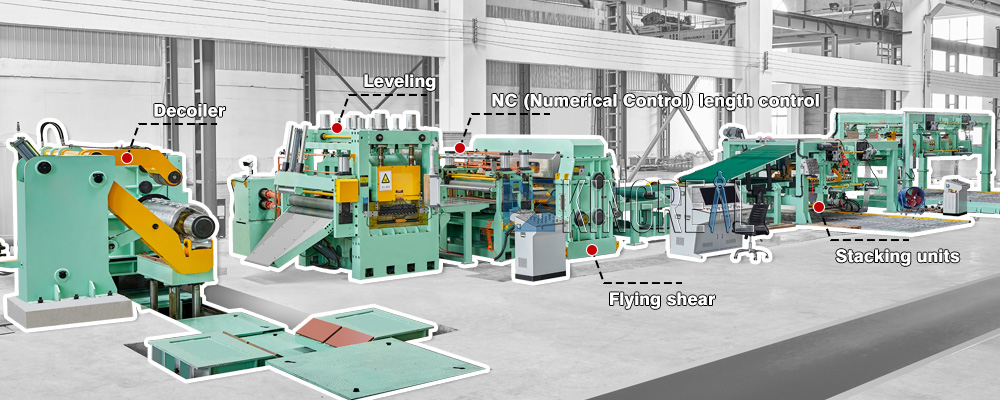

Unwinding is the first step of the stainless steel cut to length machine. The equipment unwinds the metal coils through a mechanical device. This process requires the equipment to have sufficient tension control to prevent the material from being deformed or damaged during the unwinding process.

1.2 Leveling

After unwinding, the metal coil often has certain corrugations or bends. The leveling machine flattens the surface of the metal material by applying reasonable pressure. This step is the key to ensure the quality of subsequent processing.

1.3 Shearing

After leveling, the metal material enters the shearing process. The ss cut to length line machine can shear the material into the length and specifications required by the customer, ensuring efficient production and accurate size.

1.4 Convenient for subsequent secondary processing

The high-quality metal materials provided by the stainless steel cut to length machine provide a good foundation for subsequent secondary processing. Whether it is welding, stamping or other processing technology, flat and accurate metal materials help improve production efficiency and processing accuracy.

With the acceleration of social progress, the demand for metal processing in all walks of life is increasing, and the traditional manual shearing method is gradually eliminated. In the past, enterprises relied on manual shearing, which was not only inefficient, but also had a high error rate, and it was difficult to meet the requirements of modern industry for precision and efficiency.

In this context, automated stainless steel cut to length machines came into being and became the mainstream choice of the modern metal processing industry. Automated stainless steel cut to length lines can not only improve production efficiency, but also reduce labor costs and improve product quality through advanced technology and equipment.

2.1 Improve production efficiency

Automated stainless steel cut to length machines can achieve continuous production and reduce the time loss of manual operation. SS cut to length line machines can complete more processing tasks in a shorter time, significantly improving production efficiency. Specifically reflected in the following aspects:

- Fast shearing: The stainless steel cut to length machine adopts high-speed shearing technology, which can complete a large number of shearing tasks in a short time and shorten the production cycle.

- Continuous operation: A stainless steel cut to length line can work continuously for a long time, reducing the downtime of the equipment and further improving production efficiency.

- Automated control: Modern ss cut to length line machines are equipped with advanced control systems, which can automatically adjust shearing parameters according to production needs and optimize production processes.

2.2 Save manpower

After using stainless steel cut to length machines, enterprises can greatly reduce their dependence on labor. This can not only reduce labor costs, but also reconfigure human resources to positions that require more creativity and technology. The specific manpower saving is reflected in:

- Reduced manual operation: Traditional manual shearing requires the collaboration of multiple workers, while the stainless steel cut to length line can be monitored and maintained by a small number of operators, which greatly reduces the demand for manpower.

- Reduced training costs: The skills required for operating the ss cut to length line machine are relatively low, and the company only needs to conduct basic equipment operation training, which reduces the training cost.

2.3 High precision

During the shearing process, the stainless steel cut to length machine can accurately control the shearing length and edge neatness to ensure the quality of each piece of metal material. This high-precision shearing can effectively reduce errors in subsequent processing. The specific advantages include:

- Precise shearing: The automated stainless steel cut to length line is equipped with a laser alignment and measurement system, which can monitor the shearing position in real time to ensure shearing accuracy.

- Consistency: The metal materials produced using the stainless steel cut to length machine have high dimensional consistency and can meet the strict requirements of different customers and projects.

|

|

|

2.4 Reduce material waste

The high-precision shearing of the stainless steel cut to length line can not only improve production efficiency, but also effectively reduce material waste. Through precise calculation and shearing, companies can maximize the use of metal coils and reduce the generation of waste. This advantage is reflected in the following aspects:

- Optimize material utilization: Through reasonable layout and shearing, maximize the use of each roll of metal material and reduce loss.

- Reduce procurement costs: The reduction of material waste directly reduces the procurement cost of raw materials and improves the economic benefits of the enterprise.

2.5 Improve product quality

Using stainless steel cut to length machines for metal shearing can ensure the overall quality of the product. High-quality metal materials provide reliable guarantees for the manufacture of subsequent products. The specific advantages include:

- Reduce defect rate: High-precision shearing and leveling processes reduce the defect rate of materials and improve the qualified rate of final products.

- Enhance competitiveness: High-quality products can improve the competitiveness of enterprises in the market and win the trust of more customers.

2.6 Technology upgrade and intelligence

Modern ss cut to length line machines are increasingly using intelligent technology and are equipped with advanced control systems and monitoring equipment. This enables stainless steel cut to length machines to realize functions such as remote control, data analysis and fault warning. These technical advantages have brought higher production efficiency and better management level to enterprises.

- Data monitoring: By real-time monitoring of the equipment operation status, enterprises can promptly identify problems and perform maintenance to reduce the failure rate.

- Intelligent adjustment: The ss cut to length line machine can automatically adjust the shearing parameters according to production needs to improve production flexibility.

|

|

|