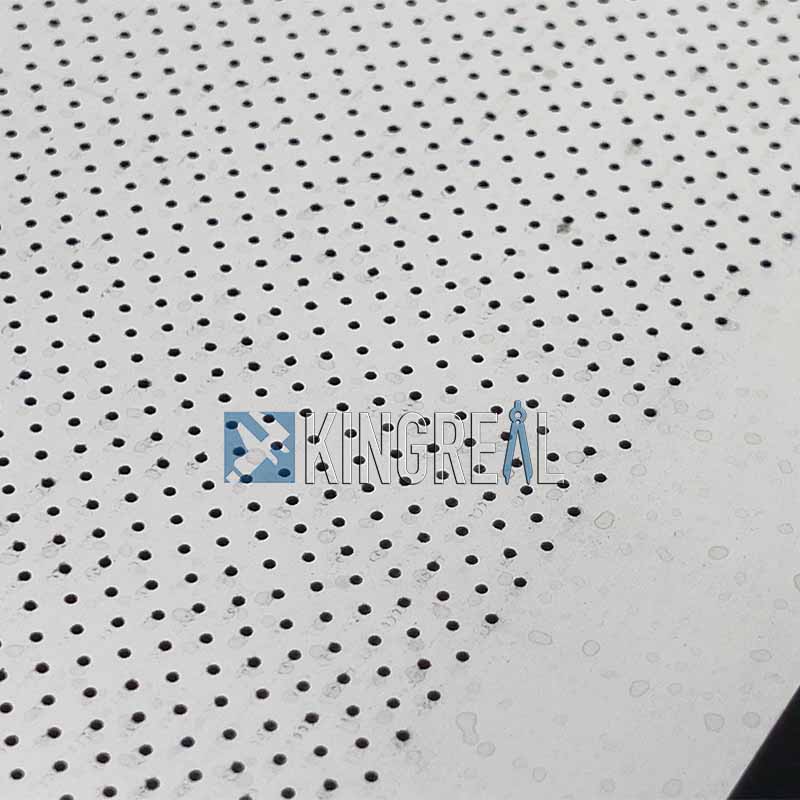

The metal sheet perforation line is an important industrial equipment specially used to punch metal coils into holes of various shapes, sizes and patterns. This technology plays an important role in modern manufacturing and is widely used in many fields such as construction, automobiles, electronics and machinery.

In this article, BRUTE STEEL SLITTER will explore the definition, advantages and different types of metal perforated making machines in depth, and strive to provide a comprehensive reference for people in related industries.

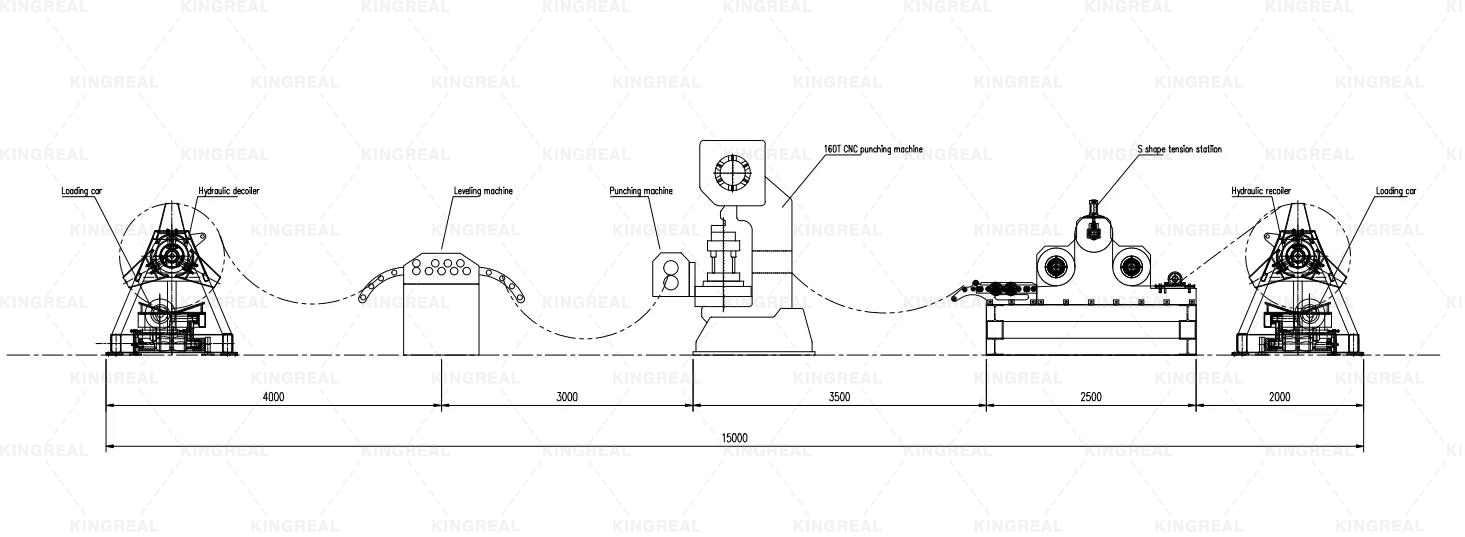

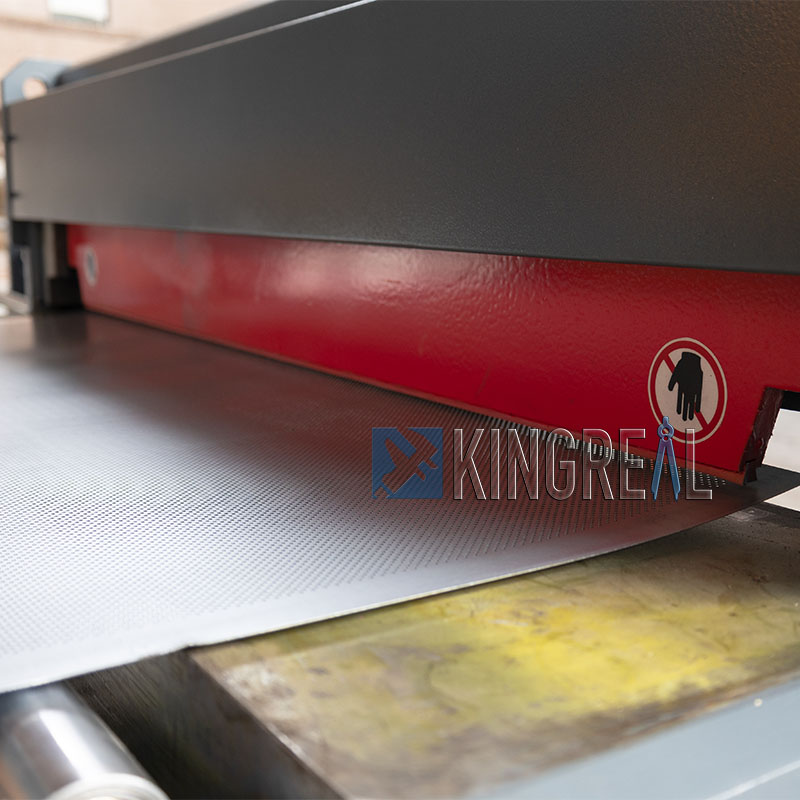

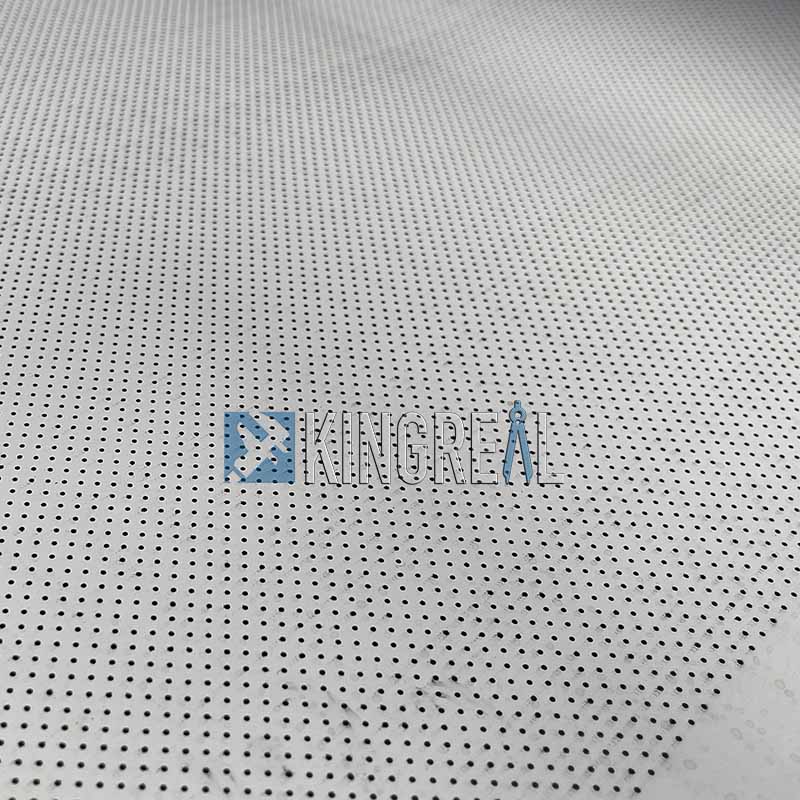

The metal perforated making machine is a device that processes metal coils into products with holes through a metal punching machine. In this process, a series of operations such as unwinding, flattening and punching are used to transform metal materials into finished products that meet specific requirements. The shape, size and pattern of the punching can be customized according to customer needs, which greatly enhances the diversity of products.

The metal perforated making machine has many advantages, which are mainly reflected in the following aspects:

1. Fast punching speed

The metal sheet perforation line is designed to improve production efficiency. Compared with traditional manual punching, the punching speed of the automated metal perforated making machine is significantly improved. Modern metal sheet perforation lines can punch dozens to hundreds of holes per minute, which is particularly suitable for large-scale production. This highly efficient production mode enables enterprises to respond quickly to market demand, shorten delivery cycles, and improve customer satisfaction.

For example, in the automotive industry, the punching speed on the metal sheet perforated machine can directly affect the assembly efficiency of the whole vehicle, thereby affecting the smoothness of the entire production process. Therefore, a fast punching speed not only increases production, but also brings greater economic benefits to the enterprise.

|

|

|

2. Improve production efficiency

Modern metal perforated making machines usually adopt fully automated control systems, which not only reduces manual intervention, but also reduces the probability of human error. The automated system can monitor the production process in real time to ensure the stable operation of the equipment. This efficient production mode enables enterprises to maintain the continuity and stability of production while reducing labor costs.

For example, on a fully automated metal sheet perforated machine, the operator can understand the production status in real time through the monitoring system and adjust the parameters in time, thereby reducing downtime. This flexibility enables enterprises to better respond to market changes and quickly adjust production plans.

|

|

|

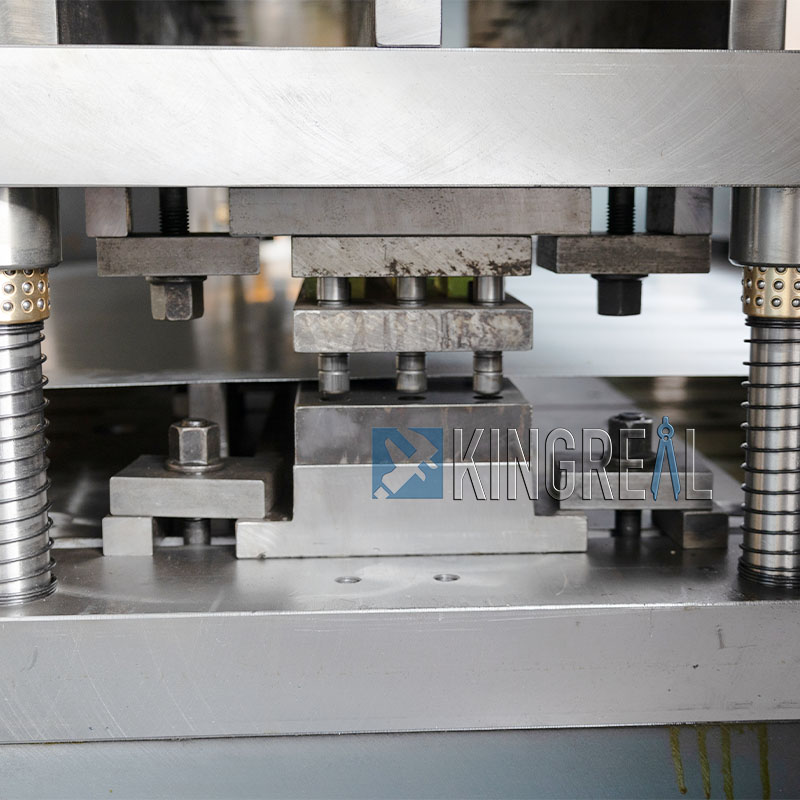

3. High precision

The metal perforated making machine can ensure that the size and shape of each hole are highly consistent. This advantage is particularly important for application scenarios that require strict control of hole diameter and hole position. For example, in the production of electronic components, the precise hole position is related to the quality of subsequent assembly. Therefore, the high precision of the metal sheet perforated machine can effectively improve the product qualification rate and reduce the rework rate.

In addition, modern metal sheet perforation line is equipped with advanced high-precision control systems that can monitor the changes in hole diameter in real time during the punching process. This precise control method not only improves production efficiency, but also enhances product consistency and meets customers' demand for high-quality products.

|

|

|

4. Compatible with a variety of metal raw materials

The metal perforated making machine can not only process common carbon steel and stainless steel, but also process a variety of metal materials such as aluminum alloy and copper. The processing requirements of different materials vary, and modern metal sheet perforation lines can achieve compatible processing of multiple materials by adjusting process parameters. This flexibility enables the metal perforated making machine to meet diverse market needs.

In practical applications, companies can choose different metal materials for punching according to customer requirements. For example, in the construction industry, aluminum alloy perforated plates are widely popular for their light weight and corrosion resistance, while stainless steel is used in more harsh environments for its strength and wear resistance. This diversity makes the metal sheet perforation line show good adaptability in different fields.

|

|

|

According to different application requirements, metal sheet perforation lines can be divided into several types. BRUTE STEEL SLITTER has launched the following three main types of metal perforated making machines according to market demand:

|

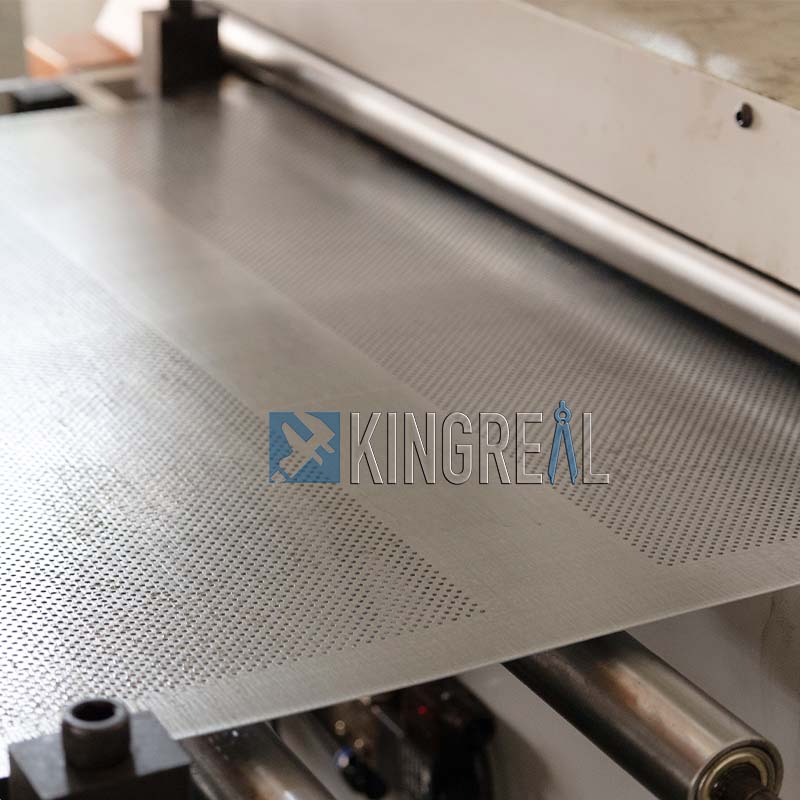

Metal sheet perforation line with rewinding

The metal sheet perforation line with rewinding is a metal perforated making machine equipped with a recoiler for customers. After the punching is completed, the perforated sheet will be rolled up to facilitate subsequent transportation and secondary processing. This type of metal sheet perforated machine is often used to produce products such as punching filter elements and baffle ceilings. The recoiler design not only improves work efficiency, but also ensures the safety and neatness of the product during transportation.

The structural design of the metal sheet perforation line with rewinding usually takes into account the convenience of transportation and storage, which can effectively reduce space occupancy. In addition, the rolled product can better protect its surface during subsequent processing, reduce the risk of scratches and damage, and further improve the overall quality of the product. |

|

|

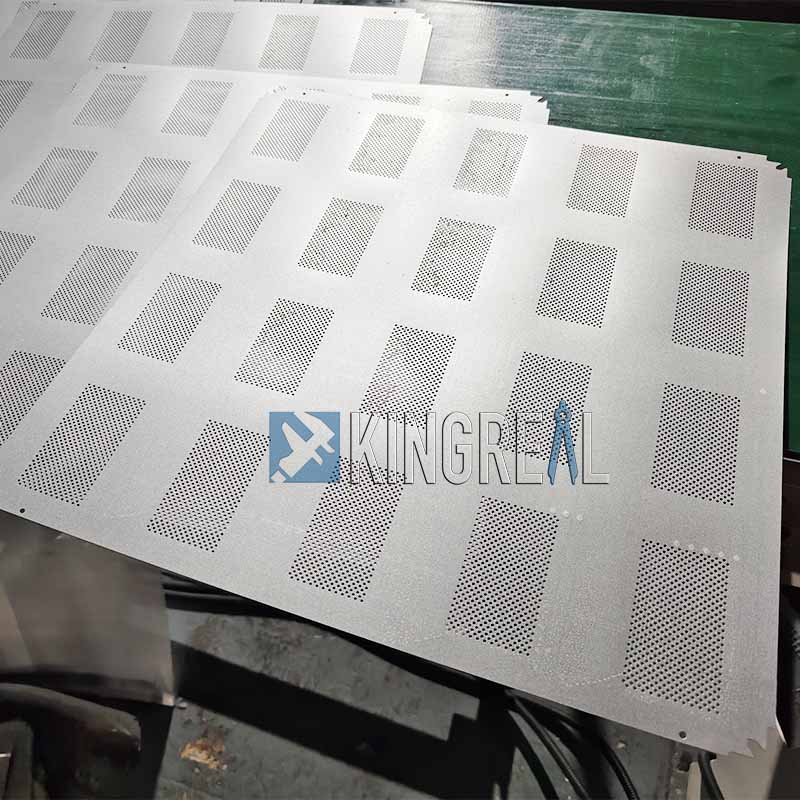

Metal sheet perforated machine with cutting

The metal sheet perforated machine with cutting is equipped with a cutting station after punching, which can be automatically sheared according to customer needs. This metal perforated making machine with cutting is often used to produce products such as wall panels. By presetting the cutting length, companies can quickly obtain finished products of the required size, reducing the workload of subsequent processing. This flexibility makes the metal sheet perforated machine with cutting a very popular choice in the manufacturing industry.

This efficient production process enables companies to complete a large number of orders in a short period of time, which is particularly suitable for projects with strict production cycle requirements. In addition, the automated design of the shearing station also improves the safety of operation and reduces the risk of injury to workers. |

|

|

Metal ceiling perforation line

The metal ceiling perforation line is specially used to manufacture various perforated ceilings, including lay in, clip in, tegular types of metal ceilings, as well as ceilings of various sizes such as 30x30cm, 60x60cm, 60x120cm, etc. The metal sheet perforation line can be used in conjunction with the metal ceiling production line to manufacture a complete perforated ceiling. Its design makes the production process more efficient and can quickly respond to market demand for ceiling products.

The metal ceiling perforation line is characterized by its diversity and flexibility, and can punch out ceilings of various shapes and structures according to different design requirements. This flexible production capacity enables companies to gain an advantage in market competition and meet the personalized needs of customers. |

|