Coil perforation line is a device that makes metal sheets into perforated metal sheets through a punching machine. It can be widely used in aerospace, shipbuilding, electronics, home appliances, construction and other industries. With the development of industrial technology, the types of coil to coil perforated making machines have gradually become richer to meet the needs of different customers.

In this article, BRUTE STEEL SLITTER will discuss in detail the three main types of coil to coil perforation lines: coil perforation line with rewinding, coil perforation line with cutting and metal ceiling perforation line, and show their applications in various fields.

Coil perforation line is an automated production equipment, which is mainly used to process metal sheets into metal plates with specific hole shapes and apertures through punching technology. These perforated metal sheets can be made into final products such as screens, filters, electronic component housings, etc. after secondary processing. The efficiency and precision of the coil to coil perforation line make it occupy an important position in modern manufacturing.

The working principle of the coil to coil perforated making machine is relatively simple, and it is mainly operated by a punching machine and related control systems. After pre-treatment, the metal sheet is pressed by the punch of the coil perforation line to form a hole of a predetermined shape on the metal sheet. This process not only improves production efficiency, but also ensures the accuracy of punching.

Based on the different needs of customers for perforated sheets, BRUTE STEEL SLITTER divides coil to coil perforated making machines into three main types: coil perforation line with rewinding, coil perforation line with cutting and metal ceiling perforation lines. Each type has its own unique functions and application scenarios.

2.1 Coil perforation line with rewinding

|

The coil perforation line with rewinding is a device that rewinds the metal sheet after punching. BRUTE STEEL SLITTER is equipped with a recoiler for subsequent packaging and transportation, and to protect the surface of the perforated metal sheet.

Specific features include:

Efficient winding: After punching, the recoiler can quickly retract the perforated metal sheet, saving space and facilitating storage and transportation.

Surface protection: The winding process can prevent scratches or other damage to the surface of the metal sheet, thereby maintaining the high quality of the product.

Diversified products: After winding, the perforated metal sheet can be made into different finished products, such as screens, filters, bread trays and baffle ceilings.

Application examples:

In practical applications, the perforated winding line is often used to produce screens and filters. Taking the water treatment industry as an example, the perforated metal sheet can effectively filter impurities and ensure the cleanliness of water. At the same time, this equipment is also widely used in the food industry to manufacture products such as bread trays to meet the needs of different customers. |

2.2 Coil to coil perforated making machine with cutting

|

The coil to coil perforated making machine with cutting is a device specially used for precise cutting of perforated metal sheets. BRUTE STEEL SLITTER is equipped with a shearing station for it, which can cut according to the customer's preset length.

The specific advantages include:

High automation: The coil to coil perforated making machine with cutting has a high degree of automation, which can reduce manual intervention and improve production efficiency.

Precise cutting: The precise design of the shearing station makes the perforated metal sheet after cutting have the characteristics of high precision, consistency and burr-free.

Diversified applications: The coil to coil perforated making machine with cutting is often used to produce motorcycle silencers, wall panels, etc. to meet different industrial needs.

Application Examples:

In the motorcycle manufacturing industry, the coil to coil perforated making machine with cutting can provide high-quality silencer pipes, which not only have good acoustic performance, but also can maintain stable performance under different environmental conditions. In addition, perforated wall panels are also commonly used in the construction industry, which can not only improve aesthetics but also provide good sound insulation.

|

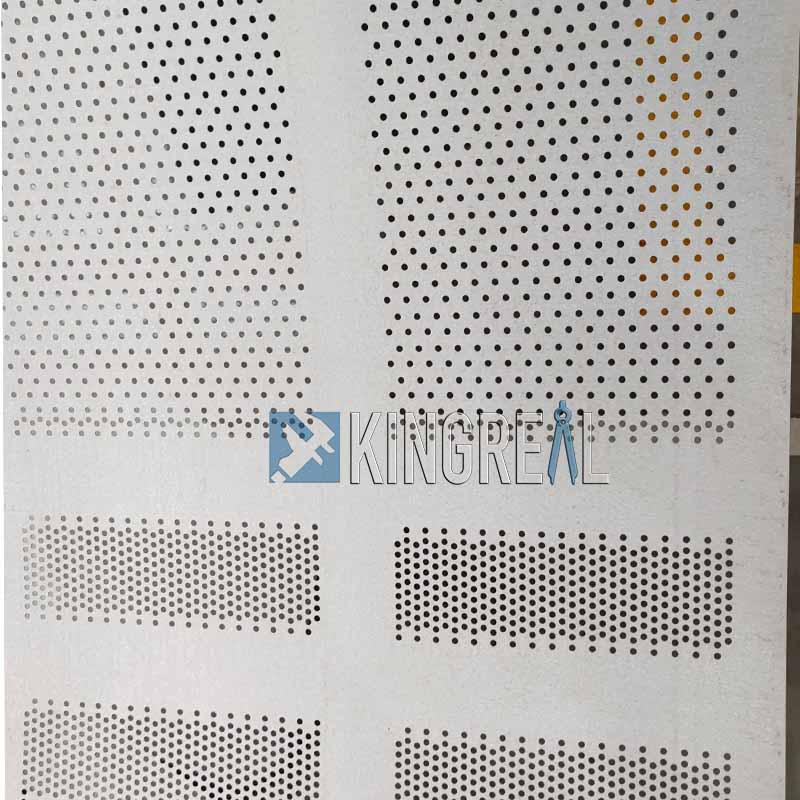

2.3 Metal ceiling perforation line

|

BRUTE STEEL SLITTER's metal ceiling perforation line can be used with the metal ceiling production line to produce different types and sizes of perforated ceilings.

Specific features include:

Diversified types: The metal ceiling perforation line can produce various types of ceilings such as clip in, lay in and tegular to meet the needs of different architectural styles.

Different sizes: According to customer needs, perforated ceilings of various sizes such as 30x30cm, 60x60cm and 60x120cm can be made.

Aesthetics and functionality: Perforated ceilings not only have beautiful appearance design, but also provide good sound insulation, which is widely demanded by the construction industry.

Application Examples:

In the construction industry, metal ceiling perforation lines are widely used in interior decoration of commercial buildings and office buildings. Perforated ceilings can not only improve the aesthetics of the interior, but also effectively reduce noise and create a comfortable working and living environment. |

No matter which type of metal perforated machine, BRUTE STEEL SLITTER's perforated metal sheets have the following advantages:

High precision: The punching process can maintain high precision to ensure that the size and position of each hole meet customer requirements.

High consistency: Through the automated control system, the quality and performance of the perforated metal sheet can be highly consistent, reducing differences in production.

No burrs: The surface of the metal sheet after punching is smooth and burr-free, which is convenient for subsequent processing and use.

|

|

|