Stainless steel slitting machine is a kind of equipment specially used for processing stainless steel metal coils. It cuts large metal coils into narrow strips of the size that meet customer requirements through main operations such as uncoiling and slitting. These narrow strips are widely used in various industries and provide basic materials for subsequent processing and production. With the continuous development of industrial production, the technology and functions of stainless steel slitting machines are also constantly upgraded to meet the needs of different customers.

Stainless steel slitting machines are used in all walks of life. BRUTE STEEL SLITTER selects five main fields for everyone to introduce:

1. Construction industry

In the construction industry, the narrow strips cut out by stainless steel slitting machines are widely used to make stainless steel guardrails, doors and windows, roofs and other building materials. Due to the excellent corrosion resistance and strength of stainless steel, building structures using stainless steel materials can effectively extend their service life and reduce maintenance costs.

Features of finished products

- Corrosion resistance: The chemical properties of stainless steel make it not easy to rust and suitable for use in various climatic conditions.

- Aesthetics: The surface of stainless steel is smooth and easy to clean, which can enhance the aesthetics of the building.

- High strength: Stainless steel is stronger than traditional materials and can withstand greater pressure and impact.

2. Home appliance industry

In the home appliance industry, the narrow strips produced by stainless steel slitting equipment are used in the shells and internal structural parts of home appliances such as refrigerators, washing machines, and microwave ovens. Home appliances using stainless steel materials not only improve durability, but also enhance the overall beauty of the product.

Finished product features

- High temperature resistance: Stainless steel can withstand high temperatures and is suitable for cooking and heating equipment.

- Hygiene: Stainless steel has a smooth surface and is easy to clean, meeting food safety standards.

- Modern appearance: The metallic luster of stainless steel adds a sense of modernity and technology to home appliances.

|

|

|

3. Automobile industry

In the field of automobile manufacturing, the narrow strips produced by stainless steel slitting equipment are used in automobile exhaust pipes, body structural parts and decorative parts. Due to the light weight and high strength of stainless steel, it can effectively reduce the weight of the car and improve fuel efficiency.

Finished product features

- Lightweight: The use of stainless steel materials can reduce the weight of the car and improve overall performance.

- Strong durability: Auto parts need to withstand harsh environments, and the corrosion resistance of stainless steel is very suitable.

- Fashionable appearance: The gloss of stainless steel makes the appearance of the car more attractive.

4. Electronics industry

In the electronics industry, the narrow strips produced by stainless steel slitting equipment are usually used to make the shell and internal structure of electronic equipment. With the development of technology, more and more electronic products use stainless steel materials to improve the stability and appearance of the products.

Finished product characteristics

- Strong anti-interference: Stainless steel has excellent electrical conductivity and can effectively prevent electromagnetic interference.

- Good heat dissipation: Stainless steel can quickly dissipate heat and extend the service life of electronic equipment.

- Exquisite appearance: The appearance of stainless steel enhances the grade of electronic products.

5. Medical industry

In the medical industry, the narrow strips made by stainless steel slitting machines are used in the manufacture of medical devices, such as surgical instruments, medical equipment shells, etc. The non-toxicity and corrosion resistance of stainless steel materials make it an ideal choice for the medical industry.

Finished product characteristics

- High safety: Stainless steel materials are non-toxic, harmless, and meet medical standards.

- Durability: Medical devices need to be frequently sterilized, and stainless steel can withstand high temperatures and chemicals.

- Easy to clean: Stainless steel has a smooth surface and is easy to clean, meeting medical and health requirements.

1. Can handle metal sheets of different thicknesses

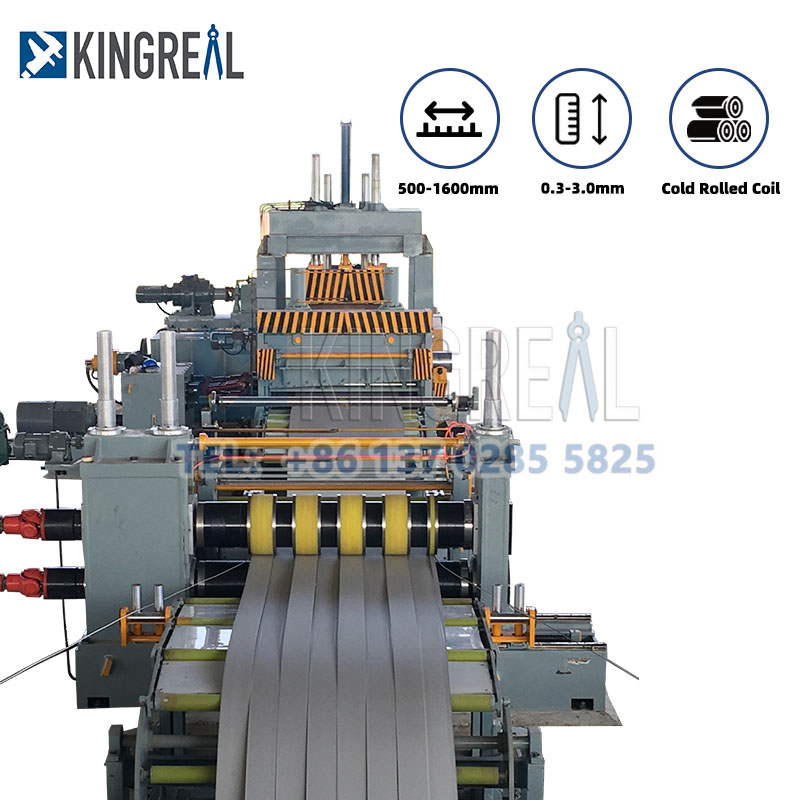

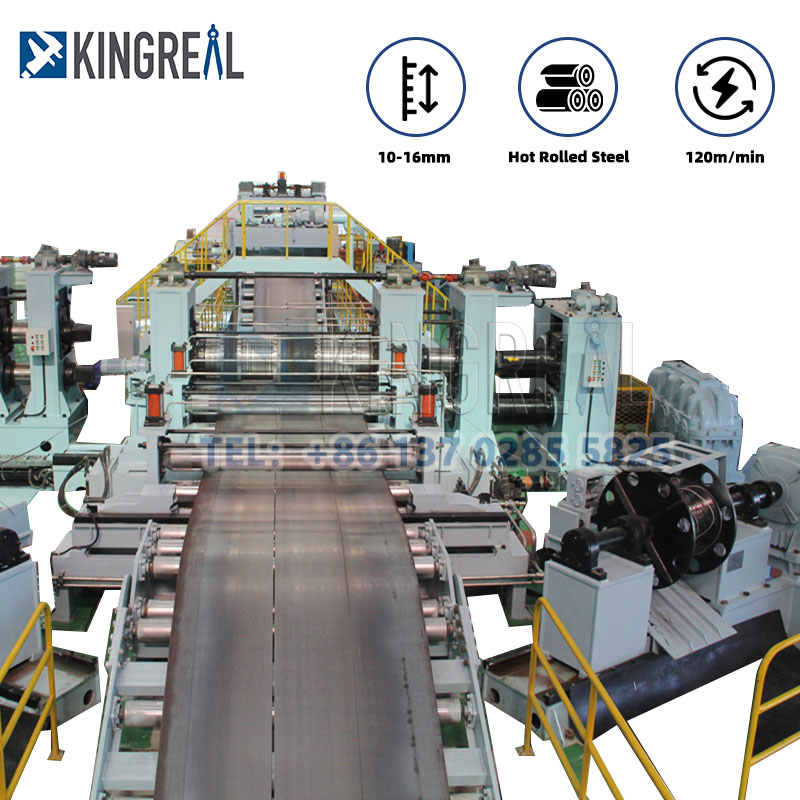

Stainless steel slitting machines can handle metal sheets of different thicknesses to meet the diverse needs of customers. Depending on the application field, the thickness of the narrow strips required by customers varies. BRUTE STEEL SLITTER has designed light gauge slitting machines, medium gauge slitting machines, and heavy gauge slitting machines, which are suitable for coils of different thickness ranges:

- Light gauge slitting machines: can slitting coils with a thickness of 0.2-3mm.

- Medium gauge slitting machines: can slitting coils with a thickness of 3-6mm.

- Heavy gauge slitting machines: can slitting coils with a thickness of 6-16mm.

|

|

|

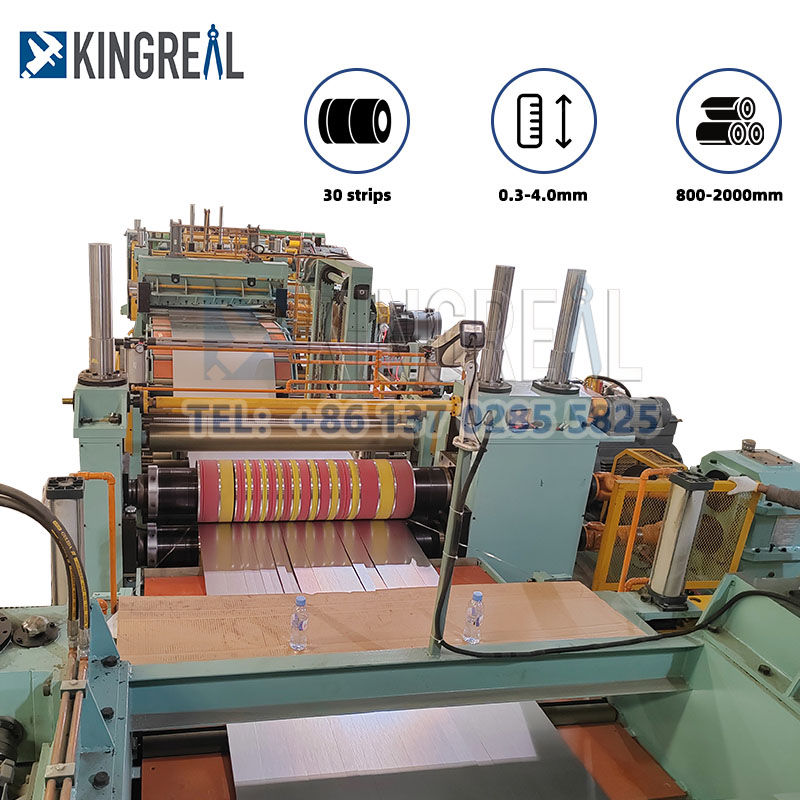

2. Customized stainless steel slitting machines

BRUTE STEEL SLITTER knows that each customer has its own unique production needs, so it is committed to the research and development of customized stainless steel slitting lines. The engineering team is able to design stainless steel slitting equipment that meet customer needs based on the drawings provided by the customer and the characteristics of the market in which they are located. For example:

- Mini slitting machine: suitable for customers with limited space and small production scale.

- Dual slitter head slitting machine: can quickly produce wider finished products and improve production efficiency.

- Belt tension stainless steel slitting machine: can produce higher precision finished products to avoid scratches and damage.

|

|

|

3. Fully automated

BRUTE STEEL SLITTER's stainless steel slitting machine consists of a series of precision components, including decoiler, feeder, traction machine, hydraulic shear, deviation correction and pressing device, main coil slitting machine, scrap material coiler, unloading trolley, hydraulic manipulator, unloading trolley, hydraulic system, pneumatic system and control system. The coordinated work of these components makes the entire slitting process without too much manual intervention, greatly improving the slitting efficiency and saving labor costs.

|

|

|

4. Can provide slitting machines of various materials

In addition to stainless steel slitting machines, BRUTE STEEL SLITTER also launches metal slitting machines of various materials. For example, CR slitting machine, PPGI slitting machine, aluminum slitting machine, hot rolled slitting machine, copper slitting machine, etc. If you have special metal coil slitting needs, please consult BRUTE STEEL SLITTER. Experienced engineers will design a stainless steel slitting equipment that meets customer needs based on actual conditions.

|

|

|