In modern manufacturing, perforated metal machines, as an important metal processing equipment, are widely used in many industries, including automobiles, electronics and construction. Ensuring the quality of metal sheet perforated machines not only directly affects production efficiency, but also affects the quality of the final product and the economic benefits of the enterprise. In this article, BRUTE STEEL SLITTER will explore how to ensure the high-quality operation of metal perforated making machines from multiple aspects, including its working principle, key factors of quality assurance and specific implementation measures.

The quality of metal sheet perforated machines has a profound impact on production efficiency and product quality. First of all, the high quality of metal perforated making machines can significantly improve production efficiency. Efficient and stable perforated metal machine can complete more work per unit time, reduce machine failures and downtime, and thus improve overall production capacity. On the contrary, if the quality of the metal perforated making machine is not up to standard, it may lead to frequent failures and downtimes, extend the production cycle, and even affect the operation arrangement of subsequent processes.

Secondly, the quality of the metal sheet perforated machine directly affects the quality of the final product. During the punching process, any slight deviation may cause inaccurate hole position and hole diameter that does not meet the specifications, which in turn affects the performance and safety of the product. For example, in automobile manufacturing, the deviation of the punching position may cause the parts to not fit perfectly, affecting the safety and performance of the whole vehicle. Therefore, ensuring the high-quality operation of the metal perforated making machine is the basis for achieving high-quality products.

Finally, good perforated metal machine quality can also help reduce production costs. High-quality equipment can complete production tasks with lower energy consumption and material waste, thereby improving the economic benefits of the enterprise. By optimizing the quality of the metal sheet perforated machine, the enterprise can maintain its advantage in the fierce market competition.

|

|

|

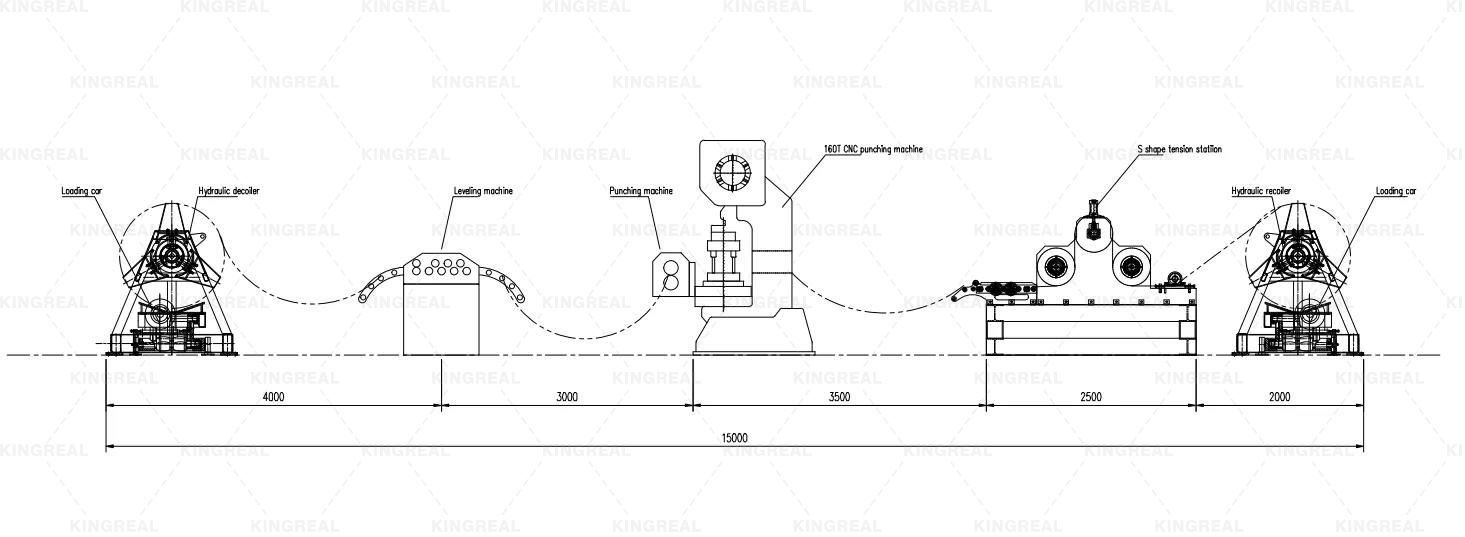

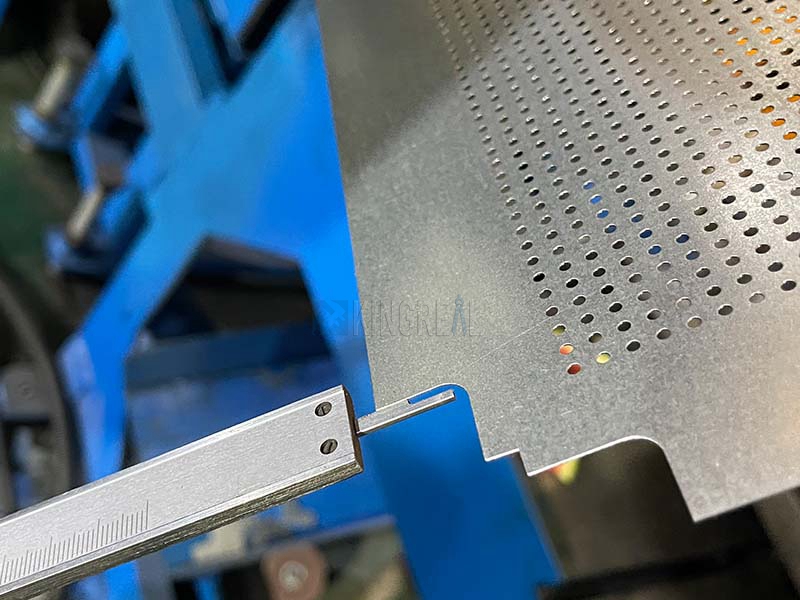

The working principle of the metal perforated making machine is mainly to use the punching technology to apply sufficient pressure to the metal material to cause local material plastic deformation to form holes. Specifically, the punching process usually includes the following steps:

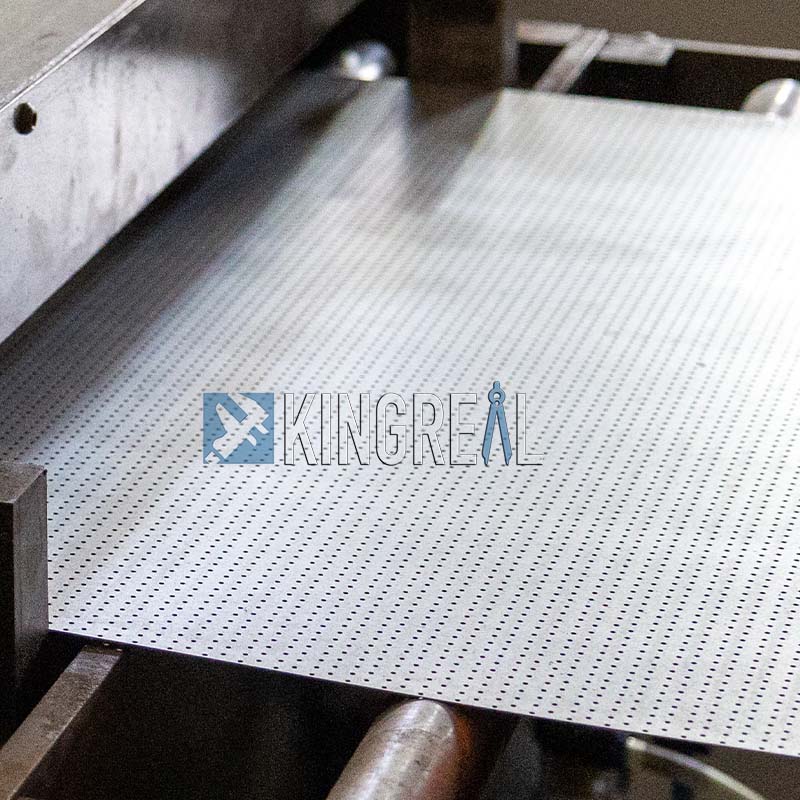

Punch pressing: The punch of the metal sheet perforated machine is pressed down by the motor and acts on the metal material. At this time, the shape and size of the punch determine the size and shape of the final hole.

Plastic deformation: When the pressure applied by the punch exceeds the yield strength of the metal material, the material undergoes plastic deformation to form a hole. In this process, the speed, pressure and material characteristics of the punch will affect the effect of punching.

Hole forming: After the punch is fully pressed down, the hole of the metal material is formed, and the shape and size of the material are basically determined.

Coiling and subsequent processing: After the punching is completed, the material continues to move to the next process, usually after shearing, bending and other subsequent processing.

The efficient operation of the perforated metal machine depends on the coordination of each of the above links. Any error in any link may lead to a decline in the quality of the final product. Therefore, understanding the working principle of the metal perforated making machine is an important basis for ensuring its efficient operation.

The key to ensuring the quality of the metal sheet perforated machine lies in the joint action of multiple factors, mainly including raw material selection, manufacturing process, quality inspection, personnel training and equipment maintenance.

3.1 Raw material selection

The selection stage of raw materials is crucial. The working performance and durability of the metal perforated making machine depend to a large extent on the metal material used. Raw materials with high hardness and good toughness can withstand greater pressure during the punching process and reduce deformation and loss of the material. BRUTE STEEL SLITTER strictly controls the procurement of raw materials, and all raw materials must undergo a strict inspection process before entering the warehouse. For materials that do not meet the standards, BRUTE STEEL SLITTER will resolutely return them to ensure the quality of each batch of materials.

When selecting raw materials, BRUTE STEEL SLITTER will also make customized choices based on the specific needs of customers. For example, for the automotive industry, high-strength steel may be required to ensure safety; while in electronic products, the conductivity and insulation of the material may be more important. Through precise material selection, BRUTE STEEL SLITTER can provide customers with punching solutions that better meet their production needs.

|

|

|

3.2 Manufacturing process

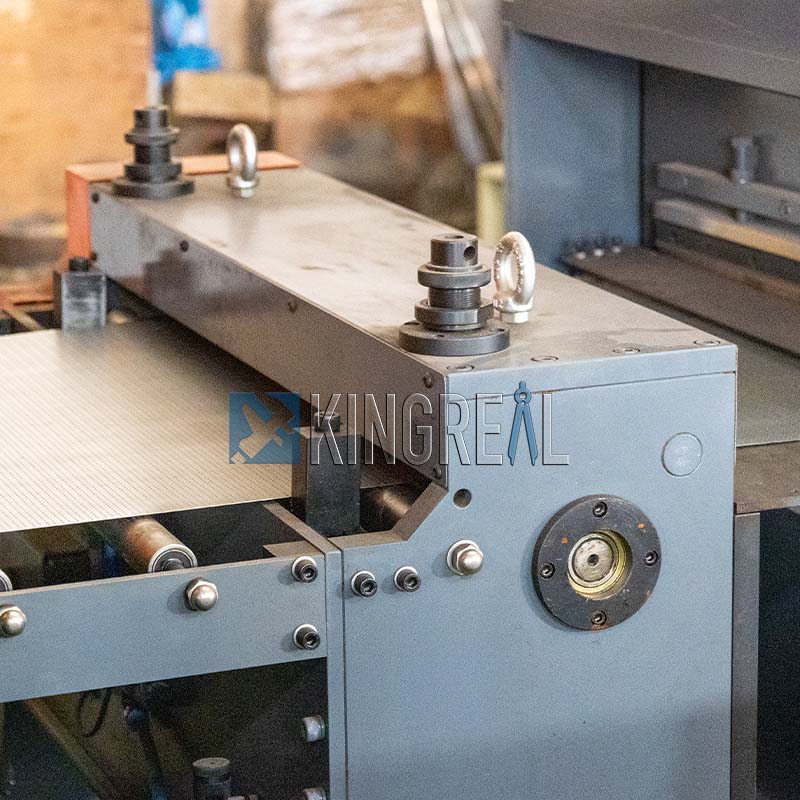

The strict implementation of the manufacturing process is another key factor in ensuring the quality of the metal sheet perforated machine. BRUTE STEEL SLITTER has formulated a strict process flow in the manufacturing process to ensure that every link has a basis. All workers are professionally trained technicians with more than ten years of machine manufacturing experience. They have a deep understanding of every detail and can find and correct problems in time during the production process.

During the manufacturing process, BRUTE STEEL SLITTER also uses advanced production equipment and technology to ensure that every component of the metal perforated making machine can meet high standards of quality requirements. For example, the processing accuracy of the punch directly affects the quality of the hole. BRUTE STEEL SLITTER uses high-precision CNC machine tools to process the punch to ensure the accuracy of its size and shape.

|

|

|

3.3 Quality inspection

Quality inspection is the last line of defense to ensure the quality of the metal sheet perforated machine. After the machine is manufactured, BRUTE STEEL SLITTER will conduct a comprehensive test on the equipment to ensure that its performance and quality meet the standards. The specific steps are as follows:

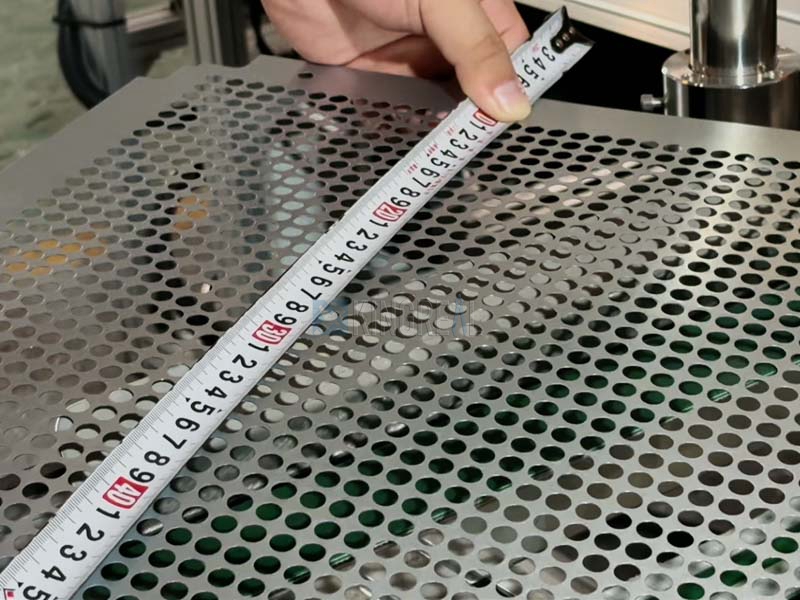

Testing stage: After the perforated metal machine is manufactured, BRUTE STEEL SLITTER puts the metal coil into the metal perforated making machine for testing. This is a very critical step to ensure that the equipment can operate normally under actual production conditions.

Debugging and optimization: If there is a discrepancy between the equipment and the plan during the trial, BRUTE STEEL SLITTER will immediately debug to ensure that the machine can meet the design requirements. If the problem is still not solved, BRUTE STEEL SLITTER will choose to remanufacture or adjust the relevant components to ensure that the equipment finally delivered to the customer is qualified.

Factory inspection: After all debugging is completed, BRUTE STEEL SLITTER will conduct a final factory inspection on the equipment to ensure that each metal sheet perforated machine meets international standards and customer needs. Only after passing all inspections will the equipment be allowed to be shipped.

This strict quality inspection process not only improves the reliability of the equipment, but also enhances customers' trust in the BRUTE STEEL SLITTER brand.

|

|

|

3.4 Personnel training

Correct operation is an important condition to ensure the efficient and stable operation of the metal perforated making machine. BRUTE STEEL SLITTER attaches great importance to the training of customer operators to ensure that they can master the use and maintenance skills of the equipment. Specific measures include:

On-site training: After the equipment is installed, BRUTE STEEL SLITTER engineers will personally go to the customer's site for operation training, and explain in detail how to use the equipment, precautions, and how to deal with common faults.

Training materials: BRUTE STEEL SLITTER will also provide detailed training manuals and video materials for customers to refer to in daily operations. These materials cover all aspects of the equipment, including operating procedures, maintenance and troubleshooting.

Regular return visits: BRUTE STEEL SLITTER will regularly return visits to customers to understand the operation of the equipment and answer questions encountered by customers during use. Through this continuous support, BRUTE STEEL SLITTER can help customers continuously improve production efficiency and product quality.

|

|

|

3.5 Equipment maintenance

The perforated metal machine needs regular maintenance in daily production to ensure its long-term stable operation. BRUTE STEEL SLITTER recommends that customers develop a detailed equipment maintenance plan, including daily inspections, regular maintenance, and troubleshooting. Specific measures include:

Daily inspections: Operators need to regularly check each component of the equipment to ensure its normal operation. For example, check the wear of the punch, the smoothness of the oil circuit, the safety of the electrical system, etc.

Regular maintenance: According to the frequency of use and working conditions of the equipment, formulate a reasonable maintenance cycle. Including cleaning, lubrication and replacement of wearing parts, etc., to ensure that the equipment always maintains the best working condition.

Troubleshooting: When the equipment fails, the operator should report it in time and make a preliminary diagnosis according to the troubleshooting manual.

|

|

|