Dear customers,

With the Canton Fair approaching, BRUTE STEEL SLITTER sincerely invites you to visit our factory to experience the professional services we provide and the various machines that can meet your needs. BRUTE STEEL SLITTER factory is located in Lianhe Industrial Area, Luocun, Nanhai District, Foshan City, GuangDong Province, China PR (only an hour's drive from the Canton Fair!), and we look forward to your visit to discuss business cooperation.

BRUTE STEEL SLITTER is a professional company focusing on the manufacture of high speed metal slitting lines and automatic cut to length lines. BRUTE STEEL SLITTER machines have successfully entered Saudi Arabia, India, Bangladesh, the United States, the United Arab Emirates, Vietnam, Russia and other countries, and have won the trust of a wide range of customers. BRUTE STEEL SLITTER is committed to providing every customer with high-quality equipment and thoughtful services.

At BRUTE STEEL SLITTER, our goal is to provide the most suitable solutions based on the actual needs of our customers. Whether you are a novice in the industry or an experienced professional, BRUTE STEEL SLITTER will serve you wholeheartedly and ensure your success in the field of metal processing.

BRUTE STEEL SLITTER has received many customers to visit the factory, such as customers from Bangladesh, UAE, Brazil, Ethiopia and other regions.

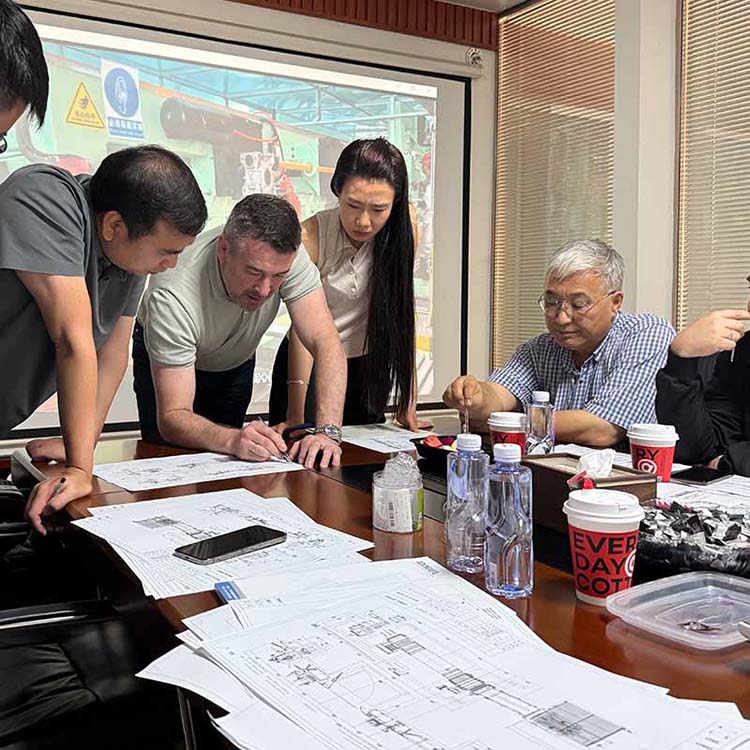

Last year, BRUTE STEEL SLITTER warmly received Ethiopian customers to the BRUTE STEEL SLITTER factory. This customer had a clear demand and needed an efficient stainless steel cut to length line.

KINGREAL STEEL SLITTER staff sent videos and pictures of the automatic cut to length line to the customer in the early stage, and invited the customer to visit the factory after the customer had a certain understanding.

The BRUTE STEEL SLITTER team took the Ethiopian customer to visit the flying shear cut to length line and invited the customer to operate the automatic cut to length line in person. During the operation of the automatic cut to length line, BRUTE STEEL SLITTER staff introduced the various components of the shearing line to him, and proposed that the biggest advantage of this flying shear shearing line is that it does not stop when shearing, the shearing speed is fast, and the production speed can reach up to 80m/min. It solves the customer's need to improve production efficiency very well. Therefore, after further communication with BRUTE STEEL SLITTER engineers and confirming the thickness of the metal sheet to be processed, the metal material, the length of the sheet to be cut, and other requirements, the cooperation was reached very quickly. The customer praised BRUTE STEEL SLITTER stainless steel cut to length line and the detailed services it provided him.

|

|

|

1. See a variety of different types of silicone steel slitting machines and stainless steel cut to length lines

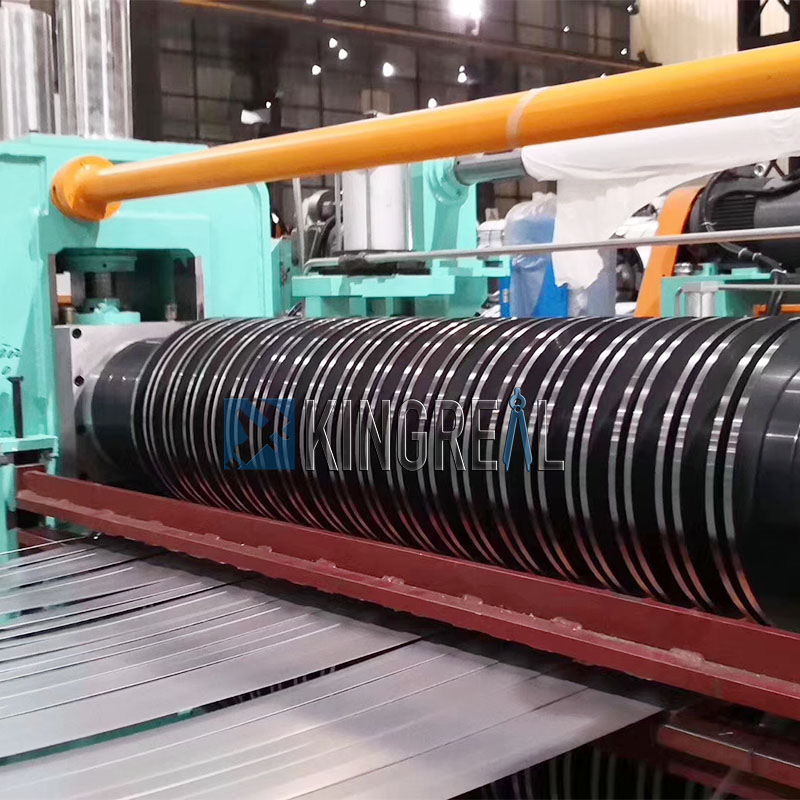

At the BRUTE STEEL SLITTER factory, you will have the opportunity to see a wide variety of high speed metal slitting lines and automatic cut to length lines. BRUTE STEEL SLITTER offers a variety of machine models, and customers can freely choose according to their actual situation. BRUTE STEEL SLITTER featured silicone steel slitting machines include:

- Dual slitter head coil slitting machine: suitable for high-precision slitting processing.

- Belt tension silicone steel slitting machine: ensures the stability of the material during processing.

- High speed metal slitting line: used for high-efficiency production needs.

- Silicone steel slitting machine with protective shield: improves safety and is suitable for various environments.

- Mini slitting machine: suitable for small-scale production use.

|

|

|

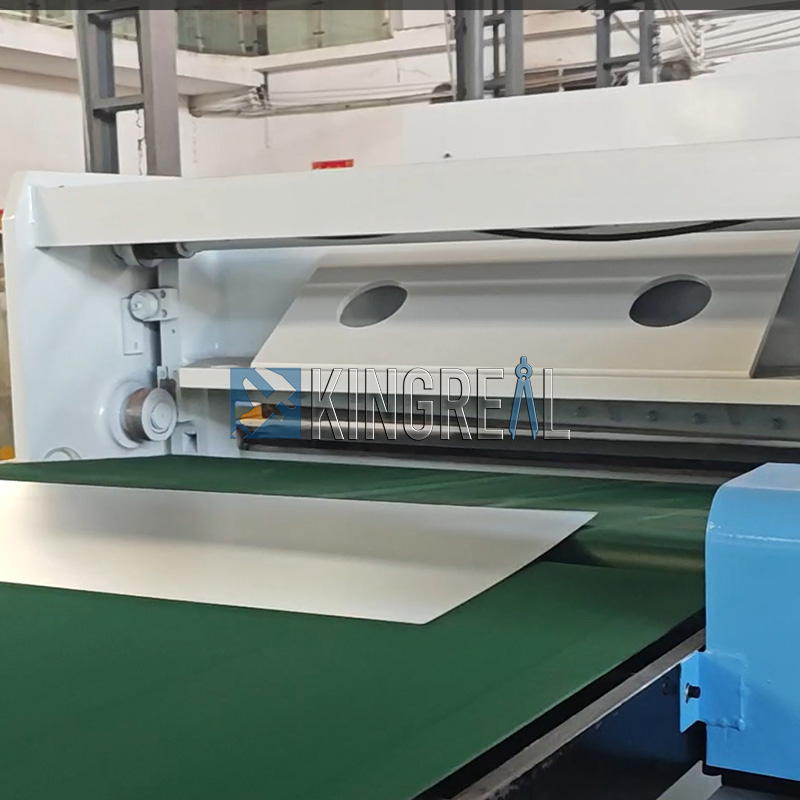

In addition, BRUTE STEEL SLITTER featured automatic cut to length lines include:

- Light gauge cut to length line: Processing metal coils with a thickness of 0.3-3mm, suitable for light and thin materials.

- Medium gauge cut to length line: Processing metal with a thickness of 0.3-6mm, suitable for medium-thick materials.

- Heavy gauge cut to length line: Can process metal with a thickness of 6-20mm to meet heavy-duty shearing needs.

|

|

|

You can also see a variety of advanced equipment such as flying shear cut to length machines, swing shear cut to length machines, stop shear cut to length machines, automatic cut to length line with double leveling machines, stainless steel cut to length line with double stackers and automatic cut to length line with lamination, which fully demonstrate BRUTE STEEL SLITTER technical strength and product diversity.

2. Customize your own machine manufacturing plan

During the visit, BRUTE STEEL SLITTER engineers will communicate with you in depth to understand your specific needs. BRUTE STEEL SLITTER will make detailed inquiries based on factors such as production scale, daily working hours, processed metal materials, and factory workshop environment. Based on your drawings and specific requirements, BRUTE STEEL SLITTER will design a tailor-made high speed metal slitting line or stainless steel cut to length line manufacturing solution for you.

This customized service is designed to ensure that the machine can fully meet your production needs, and all parameters will be set according to your actual situation to ensure the best performance and efficiency of the equipment. This personalized attention distinguishes BRUTE STEEL SLITTER from other manufacturers and ensures that every customer can get a unique solution.

|

|

|

3. Professional team introduces you to the machine

If you are new to the metalworking industry, you may not have a deep understanding of the working principle and application areas of the machine. BRUTE STEEL SLITTER professional team will provide you with a detailed introduction. BRUTE STEEL SLITTER will explain the various components, working principles and application scenarios of the silicone steel slitting machine and stainless steel cut to length line to ensure that you have a comprehensive understanding of the equipment.

BRUTE STEEL SLITTER team will also adjust the machine parameters according to the specific conditions in your area to ensure that it achieves the best results in your actual operation. In addition, BRUTE STEEL SLITTER will share some industry best practices and suggestions to help you keep improving in the field of metal processing.

After the machine is manufactured, BRUTE STEEL SLITTER engineers will go to your factory to install the equipment and provide detailed operation training for your workers. BRUTE STEEL SLITTER will ensure that your team can master the operation skills of the equipment and understand the key points of daily maintenance.

|

|

|

During the Canton Fair, BRUTE STEEL SLITTER will send a professional team to accompany you throughout the factory visit. BRUTE STEEL SLITTER will wholeheartedly answer any questions you have, share our expertise, and ensure that you feel comfortable and happy throughout the visit.

BRUTE STEEL SLITTER knows that choosing the right partner is crucial to success. We look forward to establishing a long-term cooperative relationship with you and working together to create a better future.

Please contact BRUTE STEEL SLITTER in advance to arrange your visit time. Whether you want to learn more about our high speed metal slitting lines, automatic cut to length lines, or want to discuss specific cooperation plans, the BRUTE STEEL SLITTER team will serve you wholeheartedly.

Email: [email protected]

Phone/WhatsApp: +86 13702855825

Best Regards,

BRUTE STEEL SLITTER