Metal perforated making machine is a kind of production equipment specially used to process metal coils into metal sheets with different hole diameters and hole shapes. The working principle of this sheet metal perforation machine is to form a predetermined hole shape on the metal coil through a punching die, and then perform secondary processing to achieve the final punched product. This process is widely used in many industries such as construction, automobiles, electronics, etc., meeting different requirements for the shape, strength and beauty of metal materials.

According to different process requirements, sheet metal perforation machines can be divided into three main types:

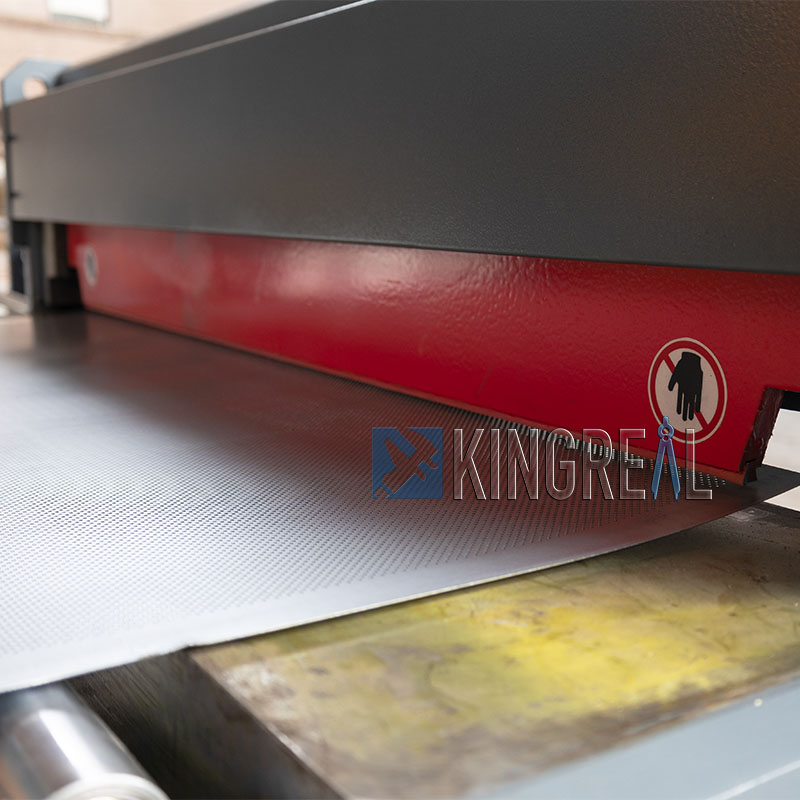

1. Metal perforated making machine with cutting

The sheet metal perforation machine is equipped with a cutting station during the punching process. After the punching is completed, the perforated metal machine can accurately shear the perforated coil into the length preset by the customer. This high-precision shearing process not only ensures the consistency of the product, but also effectively reduces material waste. The sheet metal perforation machine with cutting is suitable for making various perforated wall panels and other products, and is widely used in the construction and decoration industries.

|

|

|

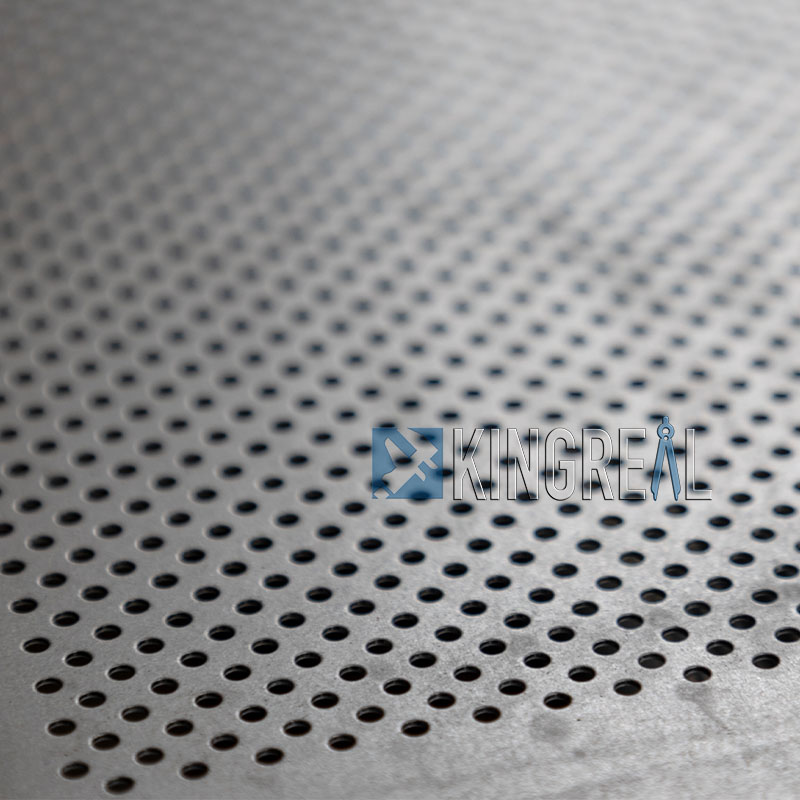

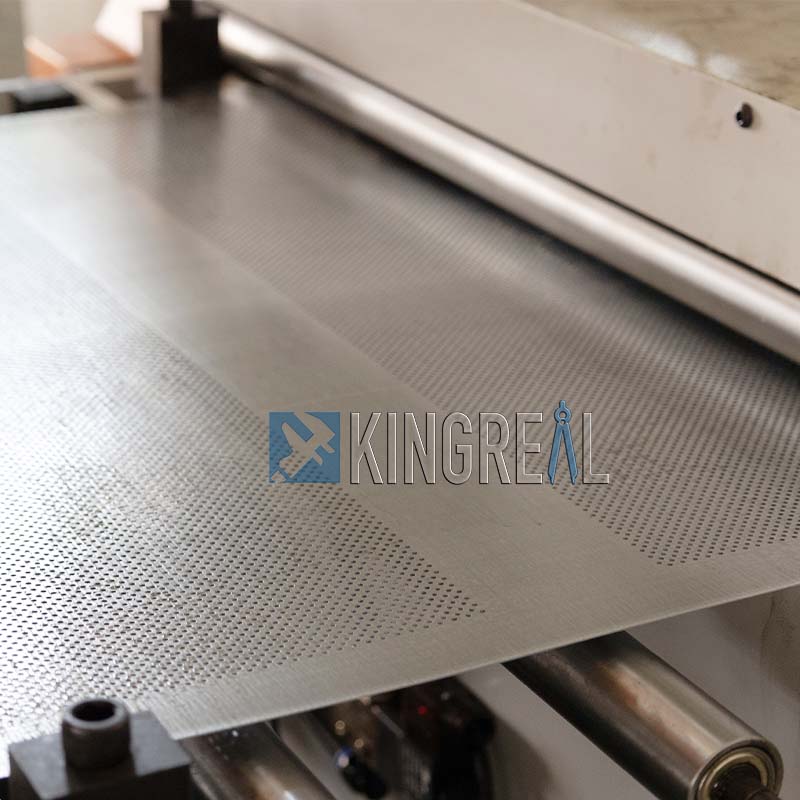

2. Metal perforated making machine with rewinding

The perforated metal machine is equipped with a recoiler based on the sheet metal perforation machine. The metal coils that have been punched will be rolled up for long-distance transportation and storage. This process can effectively protect the surface of the coils and prevent them from being damaged during transportation. The rolled metal perforated coils can be used to make perforated baffle ceilings, perforated filter elements and other products, which are widely used in ventilation, filtration and decoration.

|

|

|

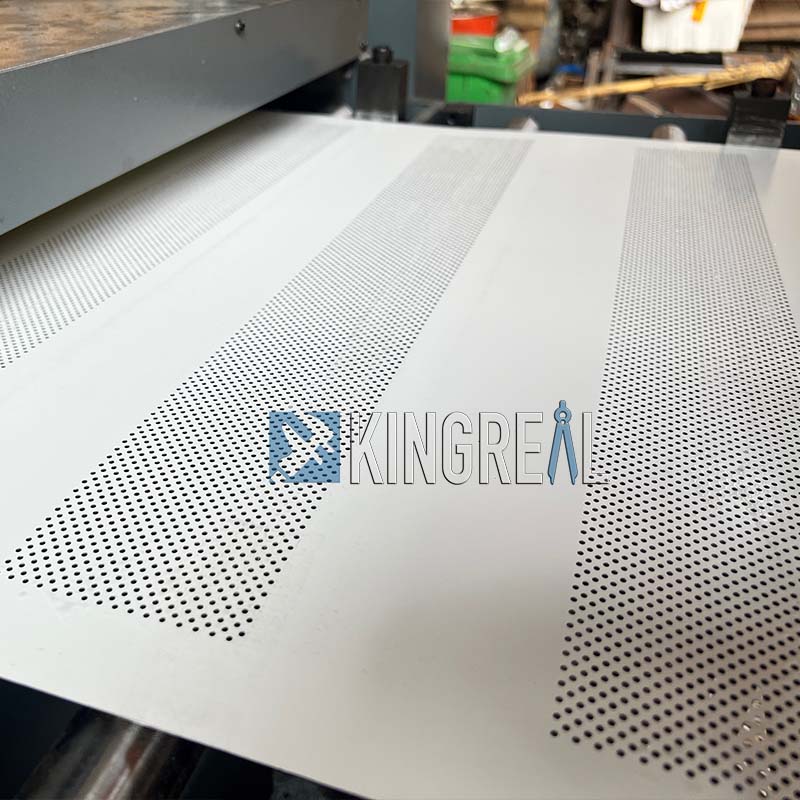

3. Metal ceiling perforation line

The metal ceiling perforation line is specially designed to be used in conjunction with the metal ceiling production line to produce various types of perforated ceilings. Common sizes include 300x300mm, 600x600mm, 600x1200mm and types such as tegular, clip-in, lay-in. Perforated ceilings not only have good acoustic properties, but also can effectively improve the indoor decorative effect, which is an indispensable part of modern architecture.

|

|

|

1. Construction industry

In the construction industry, perforated metal machines are used to make various metal decorative materials, such as perforated wall panels, ceilings, etc. These products not only have good aesthetics, but also can improve the acoustic performance of buildings and enhance the quality of indoor environment. In addition, the application of punched metal materials in building facades is becoming more and more common, adding a unique style to modern buildings.

2. Electronics industry

The demand for metal materials in the electronics industry is mainly reflected in the production of components such as radiators and housings. Sheet metal perforation machines can provide high-precision metal sheets, which play a role in heat dissipation and protection in electronic equipment. Through punching processing, the weight of metal materials can be reduced while maintaining their strength, meeting the strict requirements of electronic products for materials.

3. Automobile industry

The demand for metal perforated making machines in the automotive industry is also increasing. Punched metal materials are often used in automobile shells, internal structural parts, etc. Through punching processing, automobile manufacturers can achieve weight reduction and improve fuel efficiency while ensuring the safety and reliability of automobiles. In addition, the application of perforated materials in automobile interiors is also increasing, providing consumers with more choices.

4. Ventilation and filtration systems

The application of sheet metal perforation machines in ventilation and filtration systems cannot be ignored. The production of products such as perforated filter elements and ventilation ducts cannot be separated from high-precision punching processing. These products can effectively control airflow while providing good filtering effects, and are widely used in ventilation systems of industrial and civil buildings.

5. Furniture and home appliance industry

In the furniture and home appliance industry, perforated materials are often used to make structural parts of furniture and the shells of home appliances. The punching design can not only reduce the weight of the product, but also enhance its aesthetics. Many modern furniture and home appliances use perforated materials to meet consumers' dual needs for design and function.

|

|

|

1. Fully automated production

With the continuous improvement of the automation level of the manufacturing industry, the emergence of fully automated metal perforated making machines has greatly improved production efficiency. Fully automated production can not only reduce labor costs, but also achieve efficient production processes, giving companies an advantage in market competition.

2. High punching accuracy and consistency

The high accuracy and consistency of the perforated metal machine are important reasons for its wide popularity. Whether it is mass production or small batch customization, the perforated metal machine can ensure the quality of each product and meet customer needs. This high standard of production capacity makes the application of metal perforated making machines more common in various industries.

3. Flexible production capacity

The flexibility of the punching line enables it to adapt to different types of metal materials and hole requirements. Whether it is a standard product or a customized product, the punching line can achieve production through simple adjustments. This flexibility enables companies to respond quickly to market changes and improve their competitiveness.

4. Environmental protection and sustainable development

With the increase in environmental awareness, many companies have begun to pay attention to the efficiency of resource utilization in the production process. The efficient processing of the sheet metal perforation machine can minimize material waste and meet the requirements of sustainable development. In addition, the recyclability of punching metal materials also enhances its market appeal.