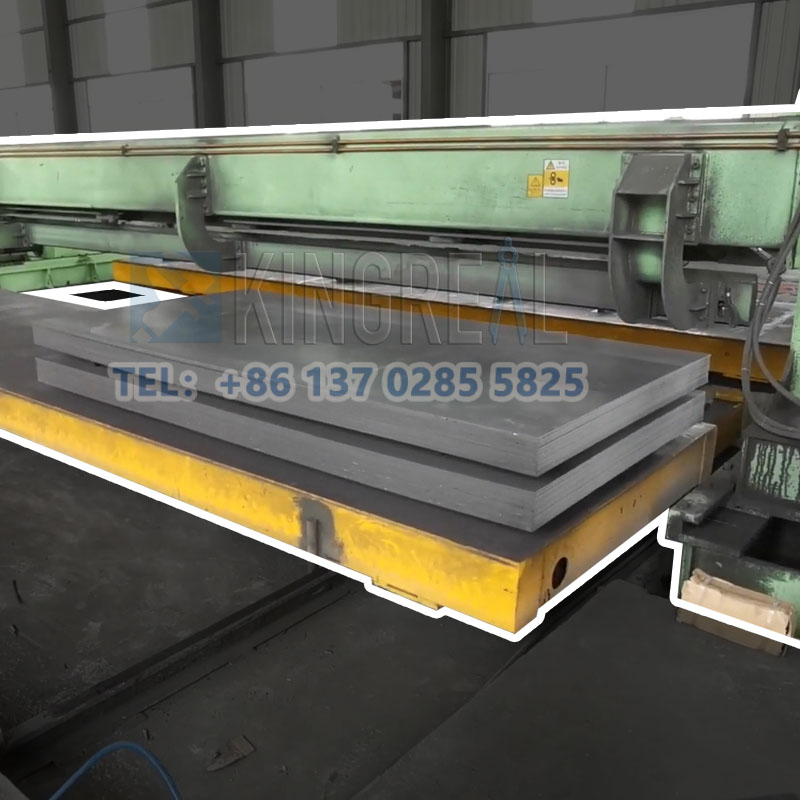

Heavy duty cut to length lines play a vital role in modern manufacturing, especially in the field of metal processing. BRUTE STEEL SLITTER heavy duty cut to length machines focus on precise shearing of metal coils with a thickness of 6-20MM to meet the specific needs of customers. This article will explore in detail the reasons for the high demand for heavy duty cut to length equipment and analyze the advantages they bring.

(1) Demand in multiple fields

Thick plate materials are widely used in multiple industries. Here are some of the main areas:

- Construction industry: Thick plate materials are often used for the support and reinforcement of building structures, especially in the construction of high-rise buildings and bridges, where thickness and strength are crucial.

- Shipbuilding: Ship structures require thick metal plates to ensure their durability and safety, especially in the construction of hulls and decks.

- Machinery manufacturing: Many large-scale mechanical equipment require thick plates as basic materials to ensure their stability and durability under high loads.

- Energy industry: In the manufacture of oil, gas and new energy equipment, thick plates are often used in the construction of pressure vessels and pipelines to ensure safety under high temperature and high pressure conditions.

(2) Technological progress drives demand

With the continuous advancement of technology, the processing technology of thick plate materials is also constantly upgrading. Modern heavy duty cut to length equipment can provide higher shearing accuracy and efficiency, allowing enterprises to better control costs and quality during the production process.

|

|

(3) Increased demand for customization

The market demand for customized products is increasing, and customers want to obtain metal plates of different sizes and thicknesses according to specific project requirements. The flexibility of heavy duty cut to length machines enables it to meet this customization demand.

(4) Improvement of production efficiency

In an increasingly competitive market environment, improving production efficiency is the key to the survival and development of enterprises. Heavy duty cut to length lines can realize automated production, greatly improving production speed and efficiency, and giving enterprises an advantage in delivery time.

(5) Cost control

By using heavy duty cut to length machines, enterprises can reduce labor costs and material waste. The automated shearing process reduces human errors and ensures that every piece of metal plate can be effectively utilized.

(1) Fully automated

BRUTE STEEL SLITTER heavy duty cut to length machine consists of a series of fully automated components such as decoiler, leveler, cut to length machine, etc. This fully automated design minimizes human involvement. The automated system can monitor the production process in real time to ensure the efficient operation of each link. By reducing manual intervention, enterprises can not only reduce labor costs, but also reduce human errors and improve overall production efficiency.

(2) Fast shearing speed

The shearing speed of the heavy duty cut to length equipment is faster than that of traditional methods, and the running speed can be adjusted according to customer needs. This flexibility allows the production line to be adjusted accordingly according to the urgency of the order to meet the diverse needs of customers. During peak production, the fast shearing speed can significantly shorten the delivery time, thereby improving customer satisfaction.

(3) High shearing accuracy

Precision is an important indicator in the metal processing industry. BRUTE STEEL SLITTER heavy duty cut to length line can achieve high-precision shearing with a very small error range. This ensures the quality of the final product, especially in applications where strict dimensional control is required, and can effectively avoid subsequent processing difficulties caused by dimensional problems.

(4) Strong adaptability

The heavy duty cut to length machine is able to process a variety of metal materials, such as steel, aluminum and stainless steel. This adaptability enables the equipment to meet the needs of different customers, thereby improving market competitiveness. Whether it is thickness or material type, the heavy duty cut to length equipment can be flexibly adjusted to adapt to different production environments.

|

|

|

(5) A wide range of metal material thicknesses that can be processed

A notable feature of the BRUTE STEEL SLITTER heavy duty cut to length machine is that it can process a wide range of metal material thicknesses, covering a thickness of 6-20MM. This range of flexibility makes BRUTE STEEL SLITTER stand out in the market and meet the diverse needs of different customers in the field of thick plate processing.

First of all, thick plate materials play an important role in many industries. The construction industry, shipbuilding, machinery manufacturing and energy all require the use of metal materials with a thickness of 6-20MM. These industries require materials to have good strength and durability in order to maintain structural stability under various extreme conditions. The BRUTE STEEL SLITTER heavy duty cut to length equipment can provide this material processing capability, helping customers achieve efficient and precise shearing during the production process.

Secondly, there are relatively few heavy duty cut to length machines on the market that can handle 20MM thick metal materials, which is a major advantage of BRUTE STEEL SLITTER. Many competitors' equipment can only handle relatively thin metal materials and cannot meet the needs of certain specific industries. BRUTE STEEL SLITTER technical capabilities enable it to take a leading position in this field and attract a large number of customers who have demand for thick plate processing. This not only enhances the company's market competitiveness, but also provides customers with more choices and flexibility.

Furthermore, the ability to process thicker metal materials also means that BRUTE STEEL SLITTER can help customers be more flexible in material selection. For some customers who need customized products, being able to choose thicker metal materials means that products with stronger structural strength can be designed, thereby improving the performance and safety of the final product. For example, in shipbuilding, thicker metal plates can significantly enhance the compressive strength of the hull and ensure safety in harsh sea conditions.

With the continuous advancement of industrialization and modernization, customers' demand for processing thick plate materials will continue to grow. With its wide range of processing thicknesses and advanced technology, BRUTE STEEL SLITTER heavy duty cut to length line will be able to continue to play an important role in future market competition. Through continuous innovation and optimization, BRUTE STEEL SLITTER will be committed to meeting the various needs of customers and providing customers with better services and solutions.

(6)Easy maintenance

The modern heavy duty cut to length equipment design focuses on user experience, and the maintenance and maintenance of the equipment are relatively simple. Regular maintenance can effectively extend the service life of the equipment and reduce the failure rate. Operators only need to perform basic daily inspections and cleaning to ensure the normal operation of the equipment, thereby reducing downtime losses.

(7) Environmentally friendly design

The modern heavy duty cut to length equipment also takes environmental factors into consideration when designing. The efficient operation of the equipment can reduce energy consumption, reduce waste gas and wastewater emissions during the production process, and meet the current requirements of sustainable development. This environmentally friendly design not only meets social responsibility, but also brings long-term economic benefits to the company.