|

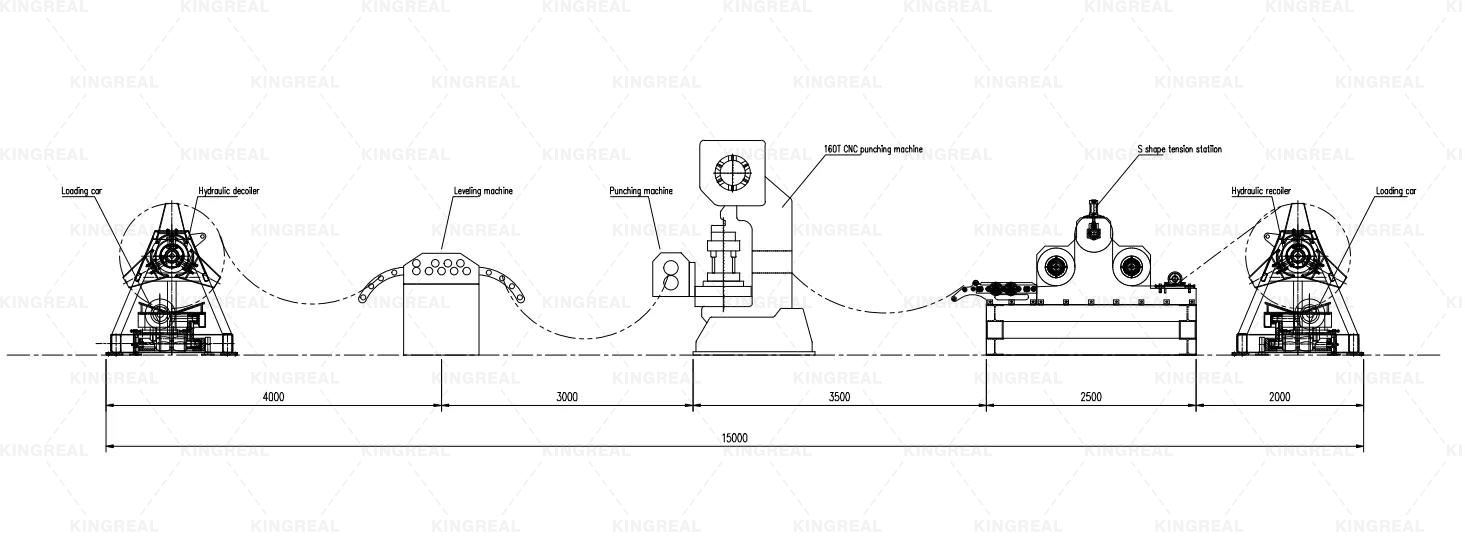

In modern manufacturing, punching technology is widely used in the field of metal processing. As an industry-leading equipment, BRUTE STEEL SLITTER sheet metal perforation machine can meet the diverse production needs of customers and punch out various types of holes. These holes not only vary in shape and size, but also play an important role in different application scenarios. Common hole types include round holes, square holes, long holes, oblique holes, and special-shaped holes (such as star holes and diamond holes). With the increasing market demand for metal sheets, the flexibility and versatility of metal sheet perforated machines are becoming more and more important. |

|

The metal sheet perforated machine mainly uses mechanical force to punch out the required holes in the metal sheet through the cooperation of the punch and the die. BRUTE STEEL SLITTER sheet metal perforation machine adopts advanced hydraulic system and servo control technology to ensure high efficiency and high precision of the punching process. The metal sheet perforated machine can handle a variety of materials, including stainless steel, aluminum, copper and other alloy materials, to meet the needs of different customers.

1.1Basic process of punching

The basic process of punching includes the steps of material loading, positioning, punching and unloading. First, the metal sheet is fed into the metal perforated making machine through the feeding device, and the positioning system ensures that the material is accurately placed. Then, the punch is pressed down quickly under high pressure, penetrating the metal plate to form a hole of a predetermined shape. Finally, the perforated material is automatically sent out to complete the entire operation process.

2.1 Versatility

The biggest advantage of BRUTE STEEL SLITTER sheet metal perforation machine lies in its versatility. By replacing different punching dies, the metal perforated making machine can punch a variety of hole types on the same production line. This design solves the shortcomings of traditional metal sheet perforated machine in production flexibility and greatly improves production efficiency.

2.2 Customized punching dies

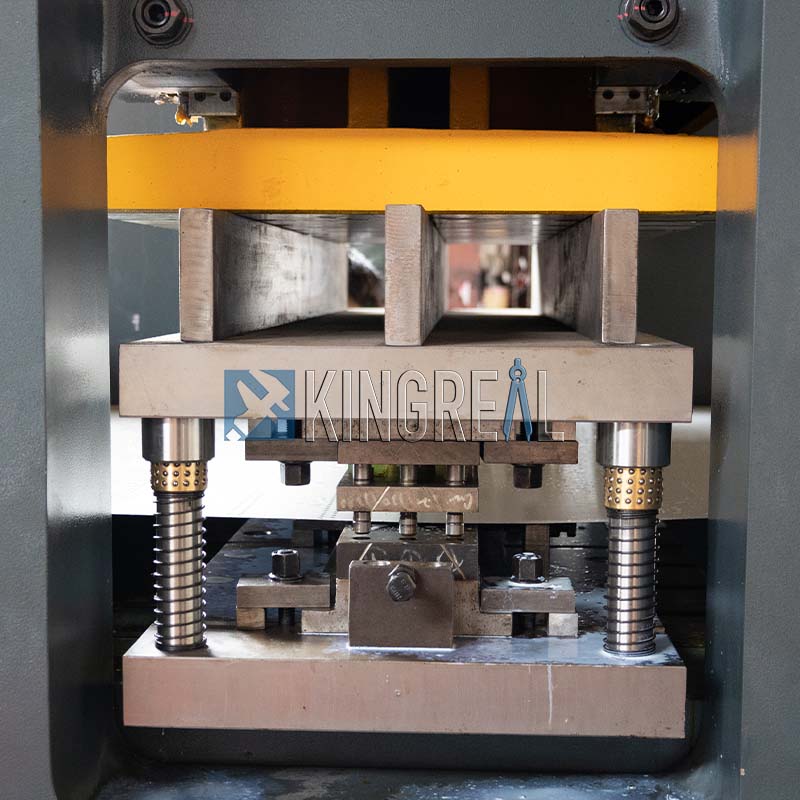

In order to meet customers' requirements for different punching needs, BRUTE STEEL SLITTER provides customized punching dies. According to the drawings provided by the customer and the actual production needs, the engineering team can design and manufacture punching dies that meet specific requirements. This process usually includes the following steps:

Demand analysis: Communicate with customers to understand their specific hole type, hole diameter, hole spacing and other special requirements.

Drawing design: According to customer needs, design detailed drawings of the punching die, including the shape, size and material selection of the die.

Mold manufacturing: Use high-precision processing equipment to manufacture the die to ensure that each die can meet strict production standards.

Testing and adjustment: After the die is completed, conduct preliminary tests to ensure that it can work stably in actual punching, and make minor adjustments if necessary.

2.3 Achieve multiple hole types by replacing the die

In the BRUTE STEEL SLITTER sheet metal perforation machine, the replacement of the die is very simple. The technicians can complete the disassembly and installation of the die in a short time to ensure the efficient operation of the metal perforated making machine. The equipment is equipped with a quick replacement device to make the process of changing the die smoother. The specific steps are as follows:

Stop preparation: Before changing the die, the metal sheet perforated machine needs to be shut down for a short time to ensure safety.

Disassembly of the old die: The technicians use professional tools to disassemble the old die, paying attention to operational safety and sheet metal perforation machine protection.

Install the new die: Install the newly designed die accurately in place, and perform necessary debugging to ensure its cooperation with the punch.

Test punching: After the new mold is installed, test punching is performed to confirm whether its performance meets the expected standards.

Through the above process, BRUTE STEEL SLITTER metal sheet perforated machine can respond quickly to market changes and meet the diverse needs of customers in different production cycles.

|

|

|

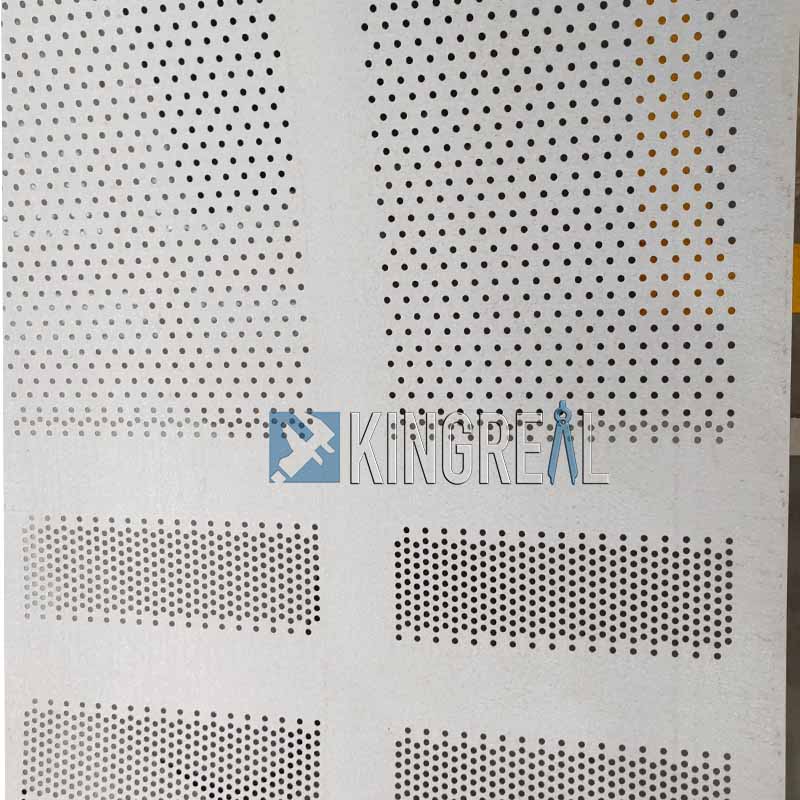

3.1 Round holes

Round holes are the most common hole types and are widely used in ventilation, drainage and electrical equipment. BRUTE STEEL SLITTER metal perforated making machine can punch out round holes of different diameters and spacings according to customer needs to meet specific design requirements.

3.2 Square holes

Square holes are usually used to fix components or connectors. They are characterized by clear edges and corners and easy notch matching. Through customized punching molds, BRUTE STEEL SLITTER can efficiently produce square holes of various sizes.

3.3 Long holes

The design of long holes is mainly used for adjustment and fixing, especially in mechanical equipment and building structures. BRUTE STEEL SLITTER sheet metal perforation machine can punch out long holes of different lengths and widths as needed.

3.4 Oblique holes

The design of oblique holes is used for special assembly requirements, and the precise control of their angles and positions is essential. BRUTE STEEL SLITTER metal perforated making machine uses high-precision punching dies to ensure that the punching of oblique holes meets the design requirements.

3.5 Special shape holes

For some special shape holes (such as star-shaped holes and diamond-shaped holes), BRUTE STEEL SLITTER sheet metal perforation machine can also achieve them through customized dies. This type of hole type is usually used in decoration or special function design, which further expands the application range of metal sheet perforated machine.

|

|

|