|

CR Slitter is a device specially designed for slitting cold rolled metal raw materials. With the continuous development of the manufacturing industry, the importance of cr slitting line in the field of metal processing has become increasingly prominent. In this article, BRUTE STEEL SLITTER will discuss in detail the functions, application areas and key role of cold rolled slitter machine in modern production. |

|

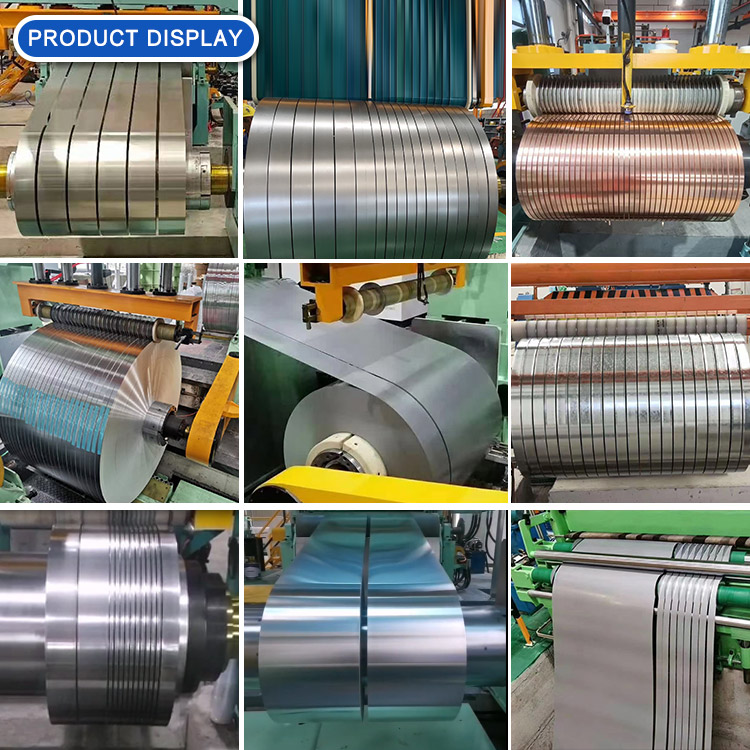

The cold rolled slitter machine is designed based on advanced automation technology. This equipment integrates a number of high-tech functions, including:

|

Automatic coil loading: This technology makes the loading process of cold rolled coils more efficient and reduces the possibility of manual intervention and errors.

Double eccentric slitting head: Equipped with a capstan and an automatic slitting tool switching device, this design ensures the accuracy and stability of the tool during the slitting process.

Double coil machine and mobile tension frame: These components help maintain the tension of the material during processing to ensure that the material will not deform during slitting.

Automatic separator switching device: This function makes the slitting process smoother, can quickly switch between different types of materials, and improve production flexibility.

Highly automated slitting coil packaging line: The automated packaging line not only improves efficiency, but also ensures the neatness and consistency of the finished product.

Through the above technology, the cr slitting line can not only provide more precise slitting width, but also ensure better slitting edge, surface quality and winding effect. |

|

Cold-rolled coils are widely used in many industries, among which the main ones with the largest demand for cr slitting lines include:

(1) Automobile manufacturing

In the automobile manufacturing industry, cold-rolled coils are widely used in body structural parts, interior parts and chassis components. Since the automotive industry has strict requirements on the strength and weight of materials, cr slitter can accurately control the width of the coils to ensure the best utilization of materials and efficient subsequent processing.

(2) Construction industry

In the construction industry, cold-rolled coils are used to manufacture various steel structures and roofing materials. As the construction industry's demand for lightweight and high-strength materials increases, cold rolled slitter machines can provide precise and uniform materials to meet the needs of modern construction.

(3) Home appliance manufacturing

In the home appliance industry, cold-rolled coils are used to produce housings and internal structural parts. Home appliance products have high requirements for the surface quality and appearance of the materials. Cr slitter can ensure that the cutting edges are smooth and improve the overall quality of the finished product.

(4) Other industries

In addition, cr slitting lines have found applications in many industries such as electronics, machinery and aviation. These industries have extremely high requirements for the precision and quality of materials, and the technical advantages of cold rolled slitter machines make them an indispensable production tool.

|

|

|

(1) Precision slitting

The main function of cr slitting lines is to slit wide cold-rolled coils into multiple narrow strips of precise widths. This process not only ensures the best utilization of materials, but also greatly improves the efficiency of subsequent processes. By adopting advanced cutting mechanisms, cold rolled slitter machines can achieve high-precision and consistent slitting, ensuring that each narrow strip meets strict industry standards.

(2) Improve production efficiency

CR Slitter significantly improve the efficiency and productivity of metal processing. By automating the slitting process, these cold rolled slitter machines can quickly process large amounts of material without human intervention. Features such as automatic coil loading, tension control system and integrated stacking mechanism streamline the entire production process and maximize production efficiency.

(3) Handle a variety of materials

CR slitting line is designed to handle a variety of cold-rolled materials and thicknesses, whether thin gauge materials or heavier coils. This versatility enables it to meet a wide range of market needs, making it widely adaptable in different production environments.

(4) Accurate quality control

CR slitting lines play a vital role in quality control of metal processing. The precise cutting mechanism ensures that the edges of the cold rolled slitter machine are straight, clean and burr-free, meeting strict industry standards. In addition, by minimizing scrap and increasing output, cr slitter optimize material utilization, thereby reducing production costs and improving overall profitability.

(5) Reduce scrap rate

Reducing scrap rate is another important role of cr slitting lines. Through precise slitting and control, the equipment is able to minimize material waste. This not only reduces the procurement cost of raw materials, but also improves the profitability of enterprises, allowing them to maintain their advantages in the highly competitive market.

With the advancement of technology and changes in market demand, cr slitting lines are also evolving. In the future, cr slitter will develop towards higher intelligence and automation, and more intelligent control systems and data analysis technologies will be introduced to achieve more efficient production management and quality control.

(1) Intelligent production

The future cr slitting lines will incorporate more intelligent functions, such as real-time monitoring of the production process through data analysis, and automatic adjustment of equipment parameters to meet different production needs. This intelligent production method will further improve production efficiency and product quality.

(2) Integration of the Industrial Internet

In the context of the Industrial Internet, cold rolled slitter machines will be able to link with other production equipment and systems to achieve intelligent management of the entire production line. This integration will enable enterprises to optimize resource allocation and improve production efficiency.

(3) Sustainable development

With the increase in environmental awareness, the design of cr slitting lines will also pay more attention to sustainability. Future cold rolled slitter machine will be more energy-efficient, reduce resource consumption and waste emissions in the production process, and contribute to the sustainable development of enterprises.