|

In modern manufacturing, perforated metal machine is a key equipment widely used in various industries. Its main function is to punch holes of different hole types and diameters on the surface of metal coils to meet the diverse needs of customers. After the production of perforated metal coils is completed, secondary processing is usually performed to produce the final product. In this article, BRUTE STEEL SLITTER will explore the key points of the sheet metal perforation machine in depth, including the importance of punching dies, the selection of apertures, common punching patterns, and the application of perforated metal machines in different industries. |

|

Purpose of punching

The core function of the sheet metal perforation machine is to punch holes of various shapes and sizes on metal coils through dies. These holes are not only used to reduce the weight of metal materials, but also to increase the permeability, aesthetics and functionality of the materials. For example, in the construction industry, perforated metal sheets are often used for decorative and functional walls. In the electronics industry, perforated metal materials are used for heat dissipation and protection of perforated metal machine.

Common punching patterns

|

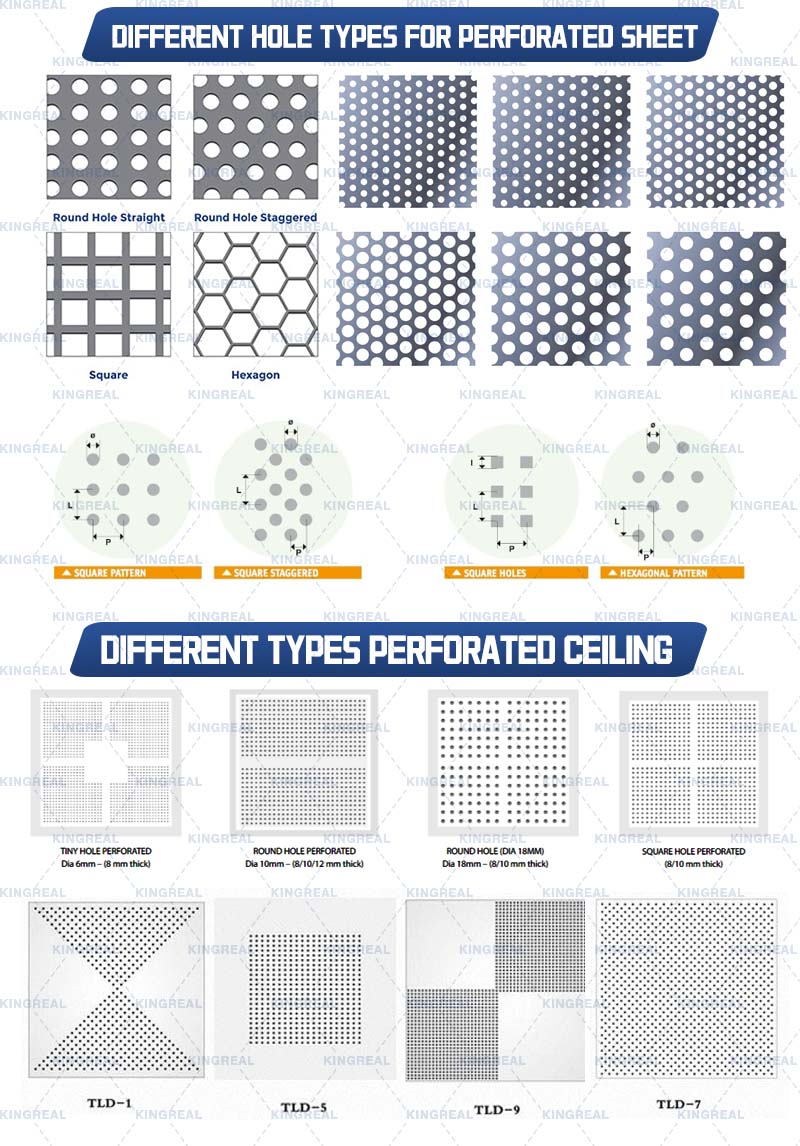

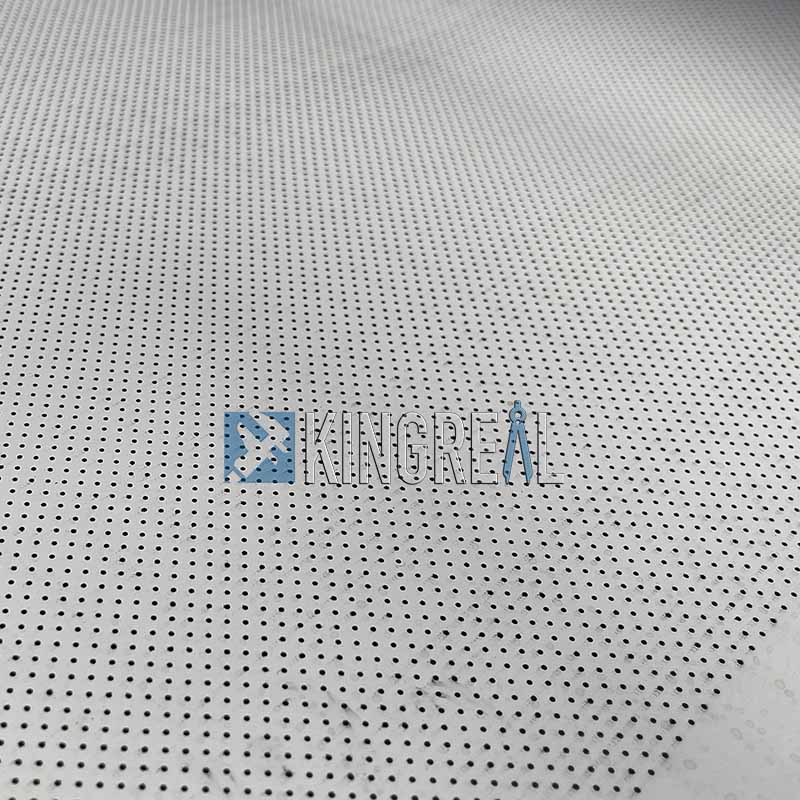

In the punching process, common punching patterns include:

Circular hole: the most basic hole type, widely used in various metal materials.

Square holes: used for specific structural requirements, providing higher bearing capacity.

Long holes: usually used for connection and installation.

Polygonal holes: customized for specific design requirements, common in decorative and functional applications.

Grid-shaped holes: used for ventilation and weight reduction, while increasing visual effects.

The choice of these patterns usually depends on the purpose of the final product and the specific needs of the customer. |

Importance of punching dies

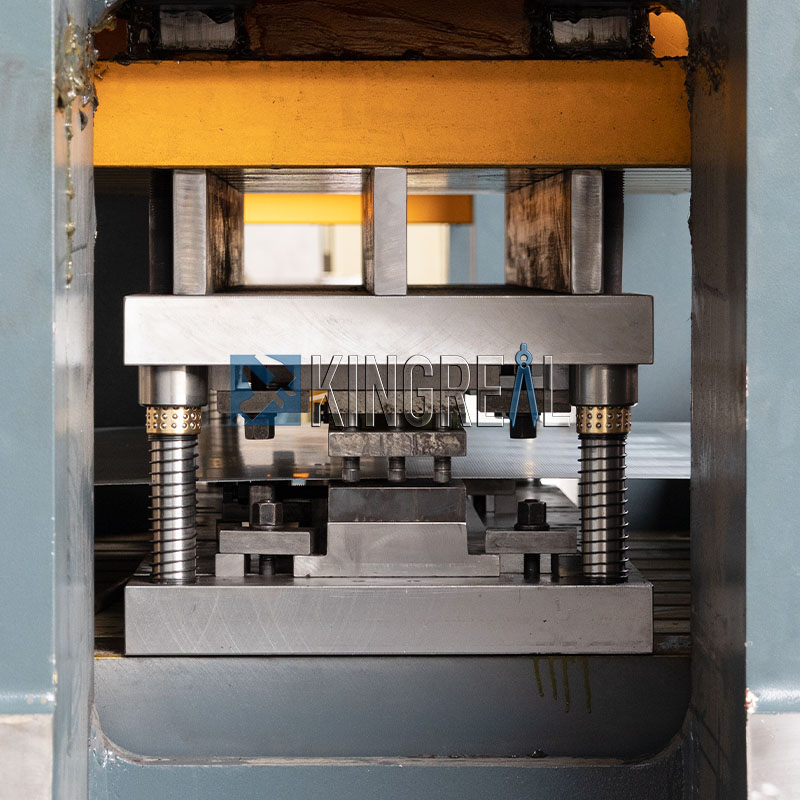

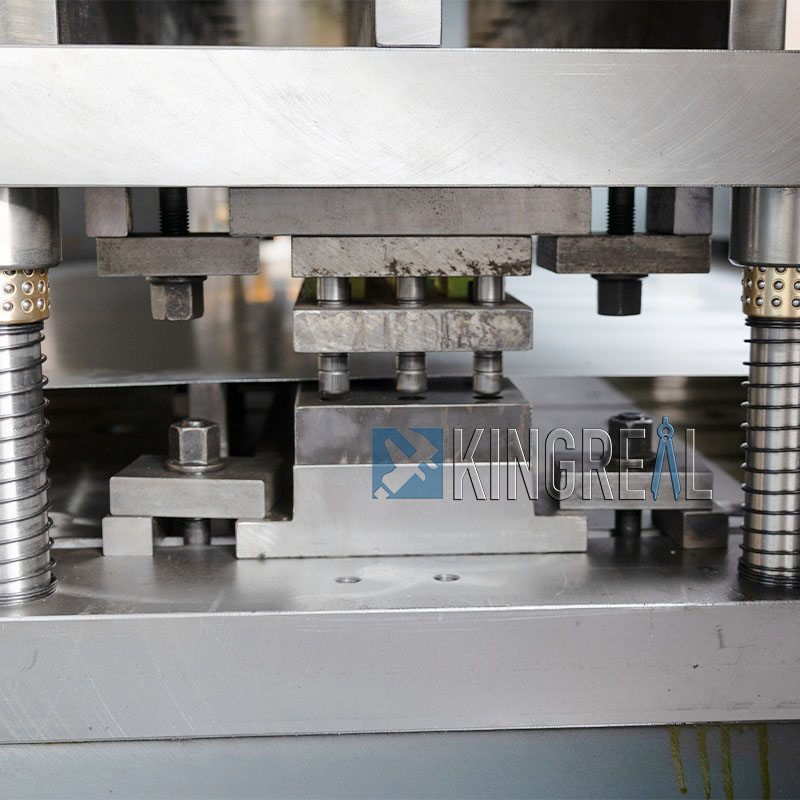

In the manufacturing process of the sheet metal perforation machine, the design and manufacture of the punching die are crucial. The punching die not only affects the quality and precision of the punching, but is also directly related to production efficiency and cost.

Function and design of punching dies

Precision requirements: High-precision dies can ensure that the size and position of each hole meet the design requirements, thereby improving the consistency of the product.

Durability: The material and manufacturing process of the die determine its service life. High-quality dies can withstand repeated punching without being easily damaged, thereby reducing production costs.

Hole design: The design of the die must take into account the punching requirements of different hole types, and can be quickly switched and adjusted to adapt to the production of different products.

The relationship between punching die and sheet metal perforation machine

The manufacturing of punching die is closely related to the performance of perforated metal machine. The quality of die directly affects the efficiency and effect of sheet metal perforation machine. For example, improper die design may lead to hole position deviation, inconsistent hole diameter, and even cause material waste. Therefore, when enterprises choose perforated metal machine, they must pay attention to the design and manufacturing process of die.

|

|

|

Selection and Innovation of Aperture

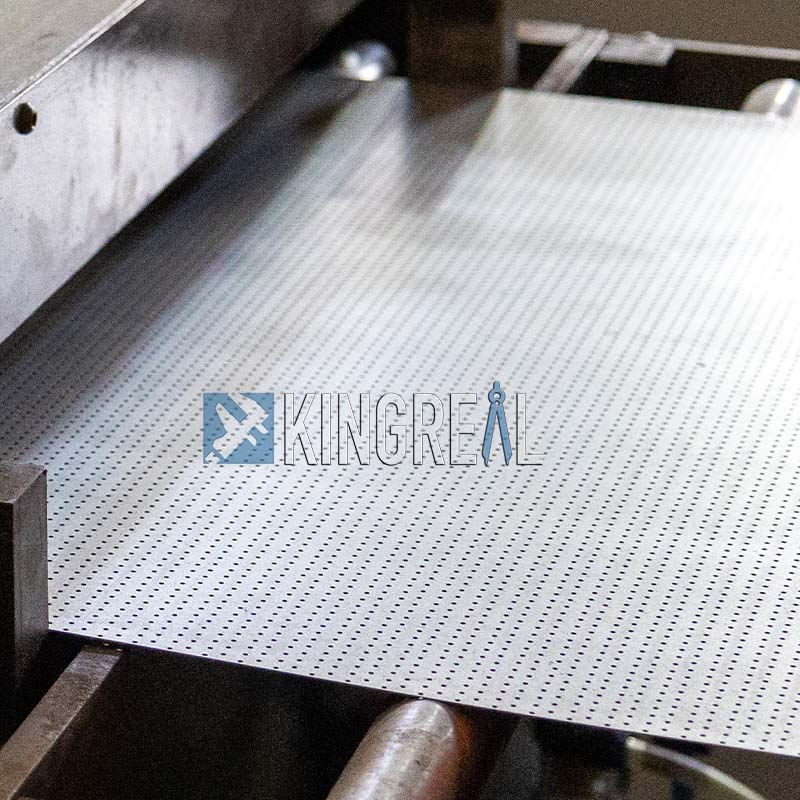

Another focus of sheet metal perforation machine is how large the aperture can be punched. The aperture not only affects the functionality and aesthetics of the product, but also directly affects the production efficiency.

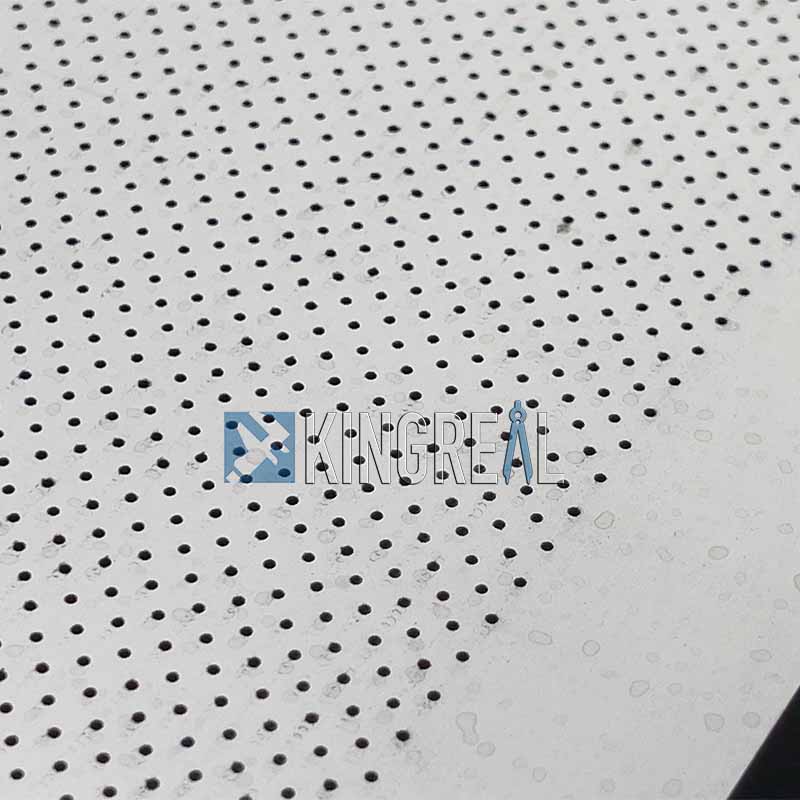

Common aperture

On the market, the common apertures are generally 1.8mm and 2.5mm. These apertures have been widely used in many industries and can meet the needs of most customers. For example, in the construction industry, the aperture of 2.5mm is often used in the production of ventilation perforated metal machine, while the aperture of 1.8mm is suitable for punching light metal sheets.

However, with the diversification of market demand, customers' requirements for aperture are also constantly increasing. Through R&D and innovation, BRUTE STEEL SLITTER engineers have successfully developed a sheet metal perforation machine that can punch out 1mm and 1.5mm apertures. This technological breakthrough not only expands the application range of the product, but also enhances the market competitiveness of the perforated metal machine.

|

|

|

Perforated metal machine is widely used in many industries. The following are several major areas:

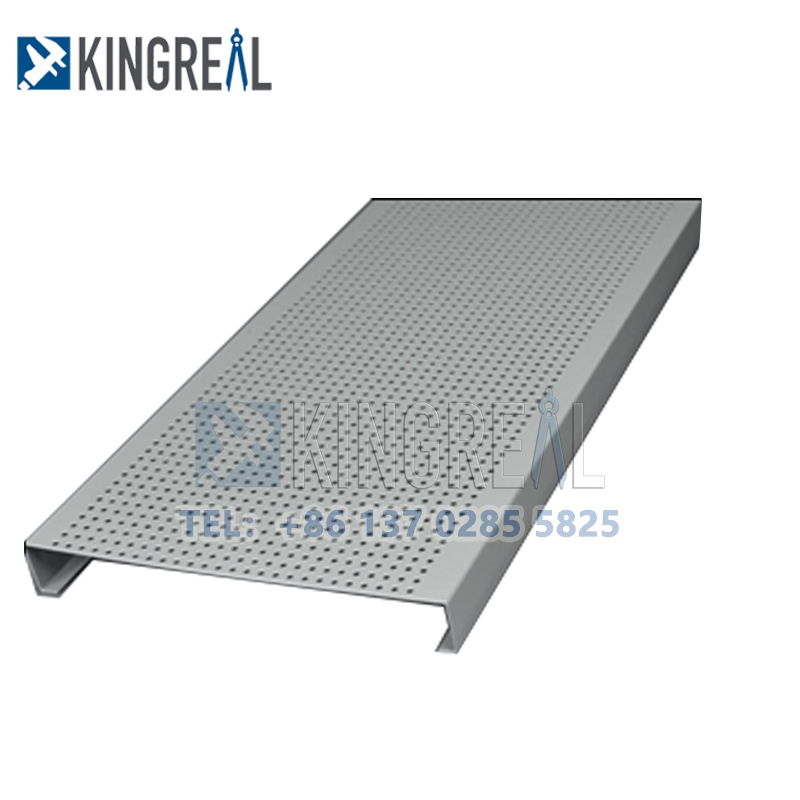

1. Construction industry

In the construction industry, perforated metal sheets are often used for decorative and functional walls. Through the design of different hole types, good ventilation and aesthetics can be achieved. The efficient production capacity of the sheet metal perforation machine makes the processing of building materials more convenient.

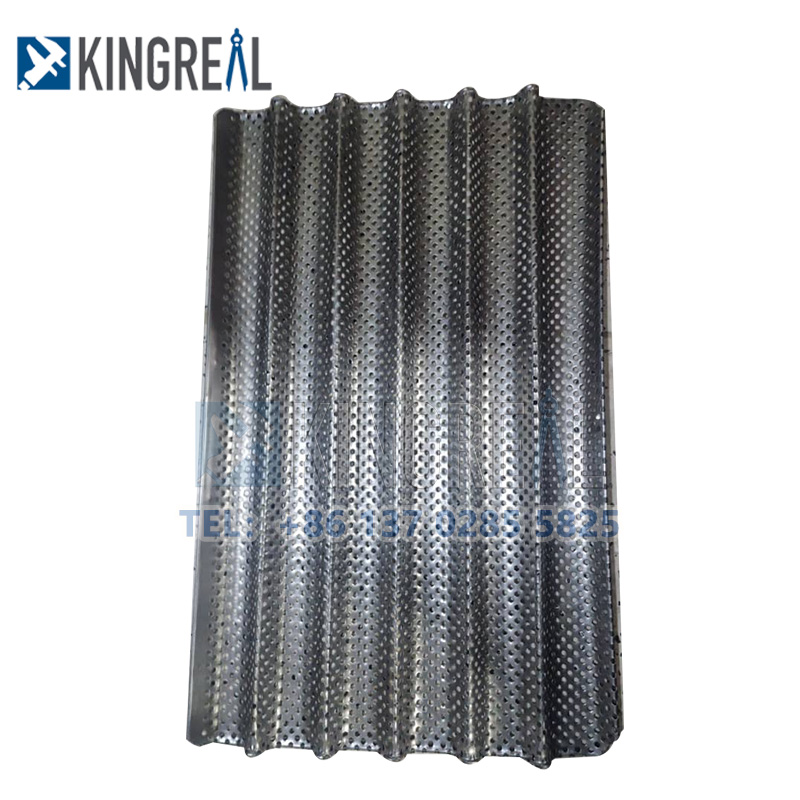

2. Automobile manufacturing

The automotive industry has extremely high requirements for the lightweight and strength of materials. The perforated metal machine can punch out the required hole type on the metal sheet to reduce the weight of the whole vehicle and improve fuel efficiency. At the same time, through precision punching, the structural strength of the vehicle body can also be increased.

|

|

|

3. Electronics industry

In the electronics industry, punched metal materials are used to dissipate heat and protect sheet metal perforation machine. The perforated metal machine can provide the required hole diameter and hole type to ensure the heat dissipation performance and safety of the sheet metal perforation machine.

4. Home appliance industry

In home appliance products, punched metal materials are often used for shells and internal structures. The metal sheets produced by the perforated metal machine can effectively improve the aesthetics and practicality of home appliance products.

5. Light industry

In light industry, sheet metal perforation machines are widely used to produce various metal products. Through the punching of different hole types and hole diameters, the diversity and market adaptability of products are greatly improved.