|

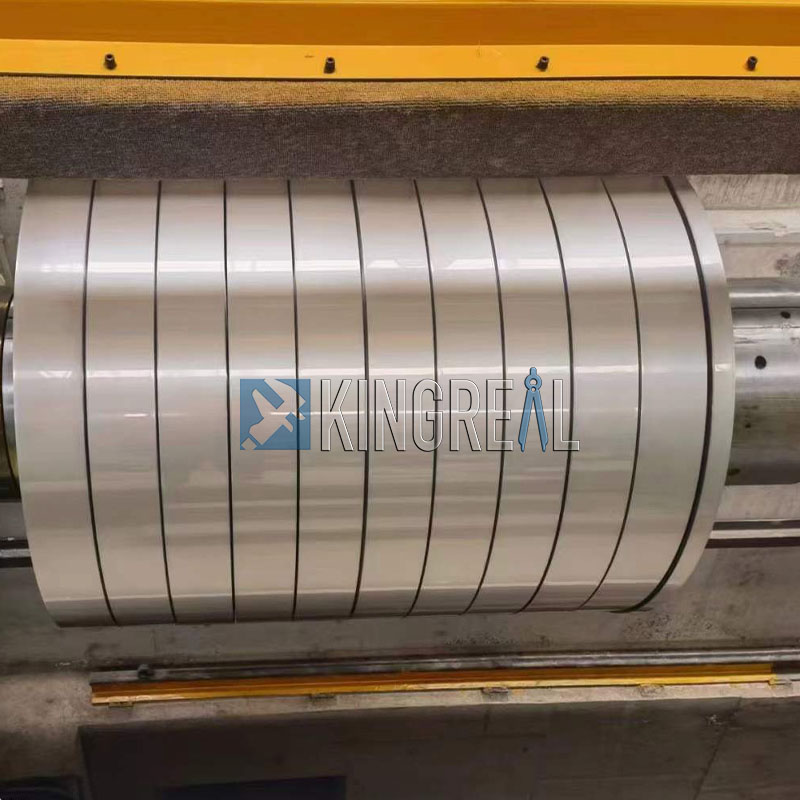

In the modern metal processing industry, the steel coil slitting line is an indispensable equipment. Its main function is to cut the metal coil into narrow strips of the width required by the customer through a series of precision components. The working process of the steel slitting machine usually includes decoiler, tension station, front loop, main coil slitter, waste collection device, back loop, separator and recoiler. In order to improve the efficiency of the steel coil slitting line, enterprises need to optimize in many aspects. In this article, BRUTE STEEL SLITTER will discuss how to improve the working efficiency of the steel slitting machine from the aspects of design stage, steel coil slitting line commissioning and steel slitting machine maintenance. |

|

(1)Introduction of fully automatic components

In the design stage of the steel slitting machine, the introduction of fully automatic components is an important measure to improve efficiency. Fully automatic components can reduce manual intervention, improve work efficiency and reduce the occurrence of human errors.

|

Stacking table: The stacking table can automatically stack the cut metal strips neatly to avoid the irregularities and inefficiency caused by manual stacking. At the same time, the design of the stacking table should ensure that the material can be received smoothly during the cutting process to reduce downtime.

Dual slitter head: The steel coil slitting line equipped with a dual slitter head can realize the simultaneous operation of two knives, increase the cutting width and speed, and significantly improve production efficiency. The design of the dual slitter head needs to ensure the synchronization of the knives and the cutting quality.

Automatic coil packaging machine: Equipped with an automatic coil packaging machine at the end of the steel slitting machine, the cut metal strips can be quickly baled to improve the efficiency of subsequent processing. The automatic coil packaging machine should have the function of adapting to metal strips of different widths and thicknesses to meet diverse production needs.

Automatic coil strapping machine: The automatic coil strapping machine can automatically wind the metal strips during the winding process, reduce manual operation, and improve work efficiency and safety. |

|

(2) Optimization of production speed

|

When designing a steel coil slitting line, it is very important to fully communicate with engineers and determine the maximum production speed of the steel slitting machine according to your own production situation. Reasonable setting of production speed not only affects production efficiency, but also affects equipment loss and cutting quality.

Reasonable speed setting: According to the thickness, width and characteristics of the material, the working speed of the steel coil slitting line should be reasonably set. Too fast speed may cause uneven cutting or even damage the knife; too slow speed will affect the overall production efficiency.

Production capacity assessment: conduct a comprehensive assessment of existing steel slitting machine to understand its maximum capacity, combine market demand, and formulate a reasonable production plan to ensure that customer needs can be met during peak periods. |

|

The debugging of the steel slitting machine is directly related to production efficiency and product quality. Before production, it is crucial to ensure that the various parameters of the machine are set reasonably.

|

(1) Adjustment and calibration of the tool |

The tool is the core component of the steel coil slitting line. The adjustment and calibration of the tool directly affect the accuracy and efficiency of cutting. Tool selection: select the appropriate tool material and model according to different materials. High-quality tools can improve cutting efficiency and extend service life. Tool angle and gap adjustment: During the debugging process, the cutting angle and gap of the tool need to be adjusted according to the characteristics of the material. Reasonable gap can ensure smooth cutting and reduce damage to the material. |

|

(2) Tension control |

Tension control is the key to ensure the stable operation of the steel slitting machine. Appropriate tension can avoid fluctuations in the material during the cutting process and ensure cutting quality. Application of tension sensor: Installing a tension sensor in the steel coil slitting line can monitor the tension of the material in real time to ensure a constant tension level during the cutting process. Tension adjustment mechanism: Design an easy-to-operate tension adjustment mechanism to ensure that the tension can be quickly adjusted during the production process to adapt to different materials and production requirements. |

Maintenance is another important part of improving the efficiency of the steel coil slitting line. Regular maintenance can ensure the normal operation of the steel slitting machine and prevent downtime due to failures.

(1) Regular inspection and maintenance

Regular inspection and maintenance of each component of the steel slitting machine can effectively extend the service life of the steel coil slitting line and improve work efficiency.

Lubrication system: Ensure the normal operation of the lubrication system, regularly replace lubricating oil, keep the mechanical parts running smoothly, and reduce wear.

Tool wear inspection: Regularly check the wear of the tool, and replace or sharpen the tool in time to ensure the cutting quality.

(2) Fault prevention and response

Establish a complete fault prevention mechanism, deal with potential problems in a timely manner, and ensure the continuity of production.

Fault monitoring system: Install a fault monitoring system to monitor the operating status of the steel slitting machine in real time, and detect and deal with abnormal situations in a timely manner.

Spare parts management: Establish a spare parts management system to ensure sufficient spare parts for key components so that they can be quickly replaced when steel coil slitting line fails, reducing downtime.

|

|

|