|

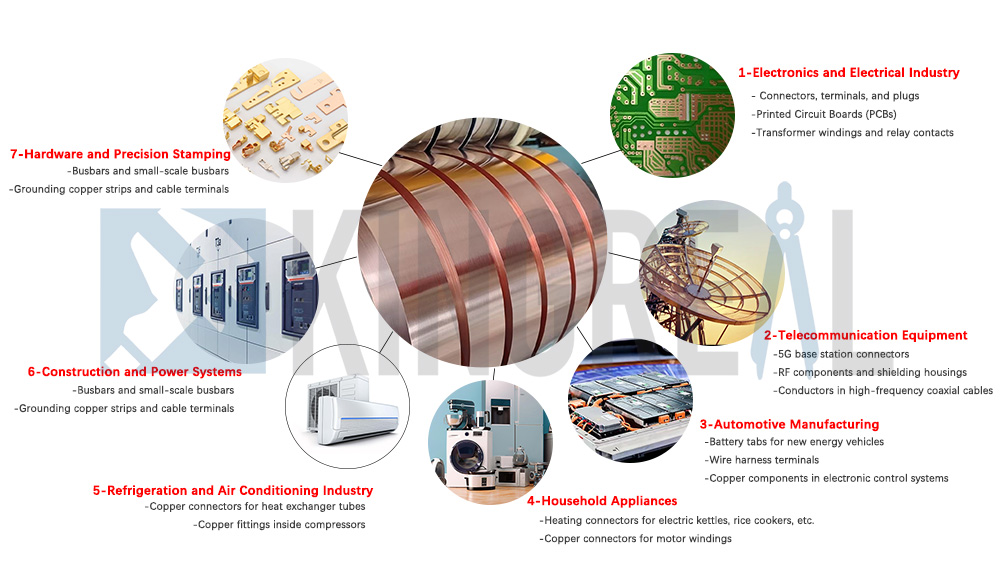

Copper strip coil slitting line is to accurately slit wide copper strips according to the size and width required by the customer to meet the requirements of different processes and applications. As an important metal material, copper strip is widely used in electronics, electrical, machinery and other fields. Its electrical conductivity, thermal conductivity and corrosion resistance make it an ideal choice for the production of electrical components, lamp holders, battery caps, buttons, seals and connectors. Copper strips of different widths meet the specific needs of various industries for conductive and thermal conductive materials, supporting the normal operation and development of various electronic equipment and electrical systems.

In order to meet the market's diverse needs for copper strips, various types of copper strip coil slitting machines have emerged. With the continuous advancement of technology, BRUTE STEEL SLITTER continues to innovate in the design and manufacture of copper strip slitting machines, striving to maintain a leading position in the market. |

|

|

1. Improved precision of copper strip coil slitting line

BRUTE STEEL SLITTER copper strip coil slitting machine series equipment has reached or even exceeded the level of many imported equipment in terms of the flatness of the slitting section and the friction of the belt surface. BRUTE STEEL SLITTER pays special attention to the design of the slitting knife seat, adopting an integrated base and a separate transmission structure. This design not only improves the rigidity of the mechanical structure, but also effectively reduces the vibration amplitude of the slitting blade, thereby improving the quality of the finished product.

Specifically, the amplitude accuracy of the slitting knife shaft reference plane is within 0.06mm. This high-precision standard ensures the service life of the tool and the accuracy of the slitting product. Such technological improvements enable BRUTE STEEL SLITTER copper strip coil slitting line to perform well in high-precision application scenarios, providing customers with more reliable production solutions. |

|

|

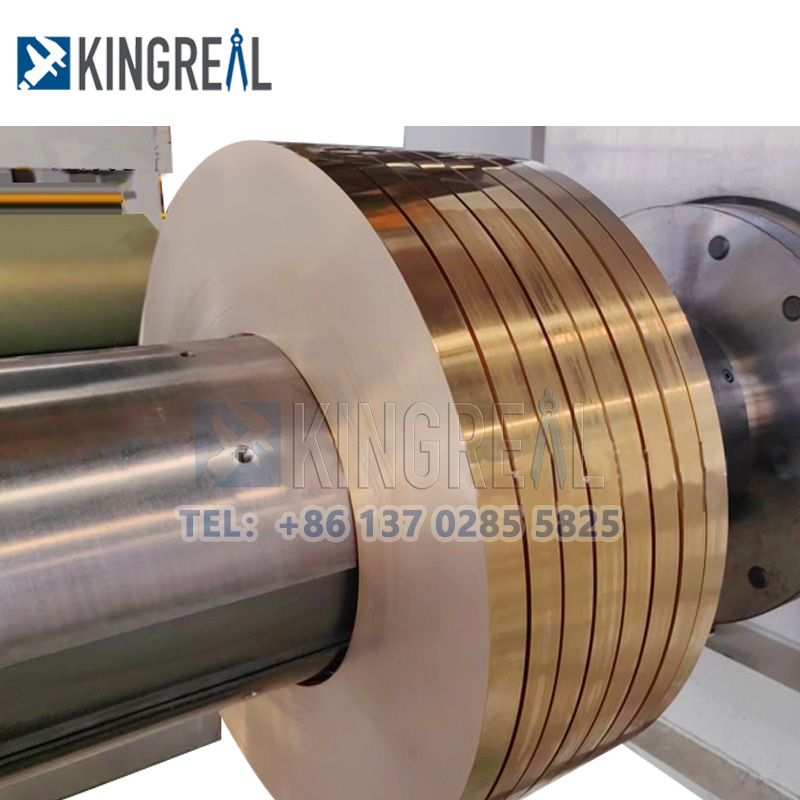

2. Improved efficiency of copper strip coil slitting line

In terms of improving the working efficiency of the copper strip coil slitting machine, BRUTE STEEL SLITTER engineers combined the company's original copper strip coil slitting line operation and process advantages to carry out comprehensive optimization and improvement. Especially in the unwinding, storage, and rewinding links, BRUTE STEEL SLITTER has optimized the design of the storage tank, tension table, and rewinding disk. These improvements not only improve the slitting efficiency, but also ensure the slitting accuracy and the end surface flatness of the finished product.

For example, the newly designed storage tank can effectively reduce the friction resistance of the material, thereby increasing the slitting speed of copper strip coil slitting machine. In actual production, BRUTE STEEL SLITTER copper strip coil slitting line can achieve higher production efficiency while ensuring high precision, making the customer's copper strip coil slitting machine more efficient. |

|

|

3. Reduce loss of copper strip coil slitting line

In the design of the copper strip coil slitting machine, BRUTE STEEL SLITTER pays special attention to the utilization rate of materials. By optimizing the design of the tool and the slitting process, BRUTE STEEL SLITTER copper strip coil slitting line can minimize the slitting loss. Specifically, BRUTE STEEL SLITTER adopts an advanced blade design, so that the cutting angle and cutting force of the blade are accurately calculated, so as to achieve a more accurate slitting effect.

In addition, BRUTE STEEL SLITTER copper strip coil slitting machine is also equipped with an intelligent control system, which can monitor any abnormal conditions in the slitting process in real time, adjust the operating parameters in time, and ensure the maximum utilization of materials. Reducing material waste not only reduces production costs, but also contributes to environmental protection. |

|

|

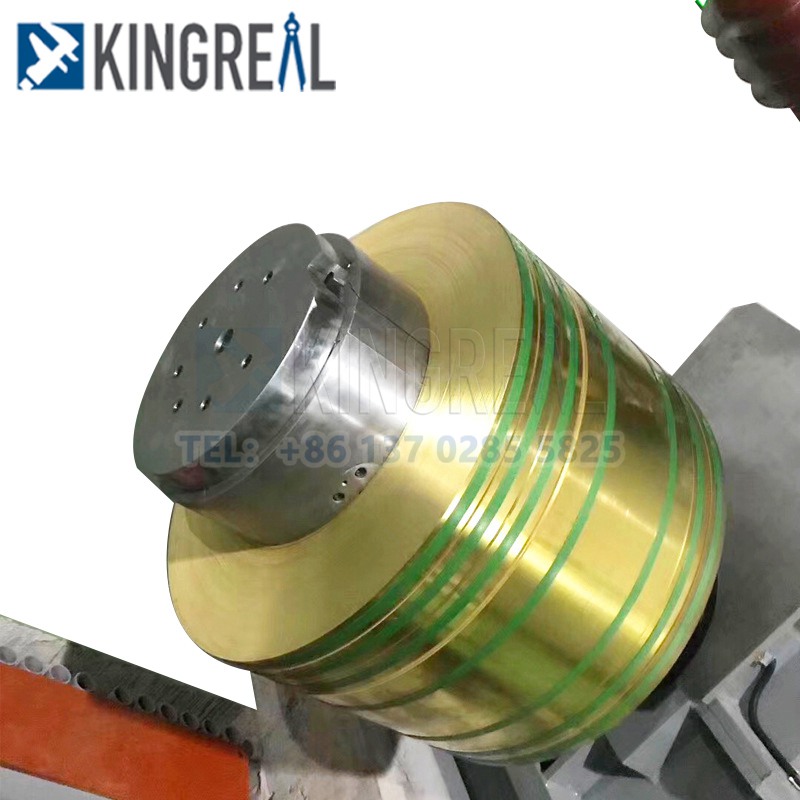

4. Improved blade hardness of copper strip coil slitting line

The hardness of copper requires the blade of the copper strip coil slitting machine to have a higher hardness to ensure the durability and cutting effect of the blade during processing. The blade material used in BRUTE STEEL SLITTER copper strip coil slitting line has been carefully selected and has excellent wear resistance and compressive strength. By adopting advanced heat treatment technology, the hardness of the blade selected by BRUTE STEEL SLITTER has been significantly improved, which can easily cope with high-strength copper cutting tasks.

The use of high-hardness blades not only extends the service life of the tool, but also reduces production interruptions caused by tool wear, thereby improving overall production efficiency. This technological innovation makes BRUTE STEEL SLITTER copper strip coil slitting machine more competitive in the market. |

|

In order to better demonstrate the technical advantages of BRUTE STEEL SLITTER copper strip coil slitting line, we have summarized several successful application cases.

|

Case 1: Electronic component manufacturer

A large electronic component manufacturer faced the problems of insufficient slitting accuracy and low production efficiency when using traditional copper strip coil slitting machines. After investigation, the company decided to introduce BRUTE STEEL SLITTER copper strip coil slitting line. After installation and commissioning, the customer found that the high precision and high efficiency of BRUTE STEEL SLITTER copper strip coil slitting machine greatly improved the overall performance of the production line, the flatness of the slitting end surface was significantly improved, and the waste loss was reduced by 20%. The customer spoke highly of BRUTE STEEL SLITTER copper strip coil slitting line and expressed that it would continue to cooperate with BRUTE STEEL SLITTER to upgrade other production equipment. |

|

|

Case 2: Battery cap manufacturer

A battery cap manufacturer needs to produce a large number of high-precision copper strips in a short time. Since the original copper strip coil slitting machine could not meet the needs, they chose BRUTE STEEL SLITTER copper strip coil slitting line. By optimizing the slitting process and tool design of copper strip coil slitting machine, the customer improved the production efficiency by 30%, while ensuring the stable quality of each batch of products. The customer said that this technological innovation brought a qualitative leap in their production. |

|

|

Case 3: Electrical connector manufacturer

In the production process of electrical connectors, material loss and slitting accuracy are key factors affecting production costs and product quality. An electrical connector manufacturer introduced the BRUTE STEEL SLITTER copper strip coil slitting line. After actual testing, it was found that the copper strip coil slitting machine not only improved the slitting accuracy, but also reduced material loss by 15%. This has significantly reduced the company's production costs and expanded its profit margins. |

|

With the continuous advancement of technology, the BRUTE STEEL SLITTER copper strip coil slitting line continues to innovate in design and function to meet the market's growing demand for efficient and high-precision copper strip processing equipment. Through a number of technological innovations such as improved precision, improved efficiency, reduced loss, and increased blade hardness, BRUTE STEEL SLITTER copper strip coil slitting machine not only provides customers with high-quality production solutions, but also occupies a favorable position in the market competition. BRUTE STEEL SLITTER will continue to be committed to technological innovation and product development to better serve our customers and promote the development of the copper strip coil slitting line industry.