|

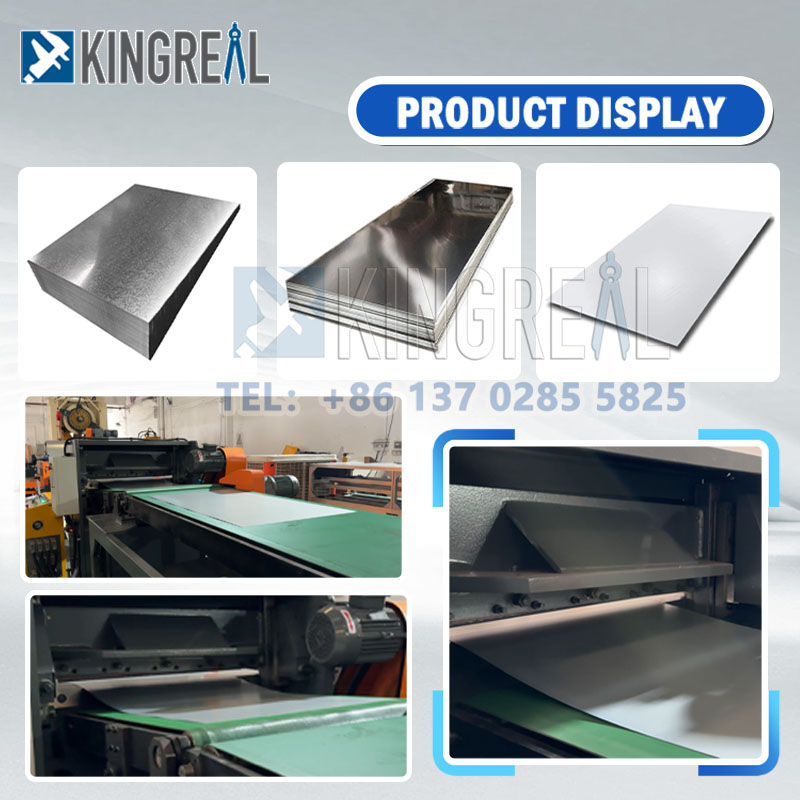

Compact Cut to Length Line is a kind of equipment specially designed for a series of forming processes such as unwinding, leveling, and shearing of metal steel sheets. With the continuous development of industrial manufacturing, compact cut to length machines have gradually gained wide application and recognition in the market due to their excellent production characteristics. Especially in factories with limited space, compact cut to length lines provide an ideal solution, enabling enterprises to process metal coils efficiently. |

|

|

The main components of compact cut to length lines include decoiler, leveling machines, cut to length machines and stacking tables. These components work together to ensure the efficiency and accuracy of the entire production process.

Decoiler for compact cut to length machine: The decoiler is responsible for unwinding the metal coil from the roll to provide raw materials for subsequent processing. It is designed to ensure the stability of the material and avoid distortion or damage during the unwinding process.

Leveling machine for compact cut to length line: The main function of the leveling machine is to level the coil and eliminate deformation caused by curling or improper storage. By adjusting the pressure and speed, the leveling machine can ensure that the metal sheet reaches the best condition before shearing.

Cut to length machine for compact cut to length line: The cut to length machine is the core part of the compact cut to length line, responsible for shearing the flattened metal sheets into the required length. Its cutting accuracy and speed directly affect production efficiency and finished product quality.

Stacking table for compact cut to length machine: The stacking table is used to automatically stack and pack the sheared metal sheets, reducing manual intervention and improving work efficiency. It is an important part of achieving efficient shearing. |

|

|

1. Small footprint

Compared with traditional standard compact cut to length machines, one of the biggest advantages of compact cut to length lines is that they occupy a small area. This feature is particularly suitable for customers with limited factory space. With the compact cut to length machine, companies can achieve shearing goals in a limited space, which not only improves space utilization, but also avoids the inconvenience caused by the equipment taking up too much space. |

|

|

2. Efficient production capacity

The compact cut to length line is designed with production efficiency in mind, and its production speed can reach 20 m/min. This speed enables small and medium-sized enterprises to achieve efficient production when processing low-thickness metal coils. The efficiency of the compact cut to length machine is particularly evident when processing metal coils with a thickness range of 0.2-3mm. |

|

|

3. High degree of automation

The compact cut to length line is equipped with an automatic stacking table, which can automatically pack and stack after the shearing is completed, significantly reducing the need for manual participation. This feature not only improves work efficiency, but also reduces labor costs, which is the goal pursued by modern factories. |

|

|

4. Simple operation

The operating table of the compact cut to length machine is simple and clear in design, and is equipped with an operating interface in Chinese and English, which is convenient for operators with different language backgrounds to use. If the customer comes from a country with other languages, BRUTE STEEL SLITTER will make corresponding adjustments according to the needs. This humanized design greatly reduces the difficulty of operation and improves the flexibility of production. |

|

|

5. High cost-effectiveness

The compact cut to length line is particularly suitable for customers with low processing output and limited budget. For those companies that are just starting out, the compact cut to length machine helps them to transform and upgrade the coil processing production process with its relatively low investment cost and flexible production capacity. |

|

With the continuous advancement of industrial automation and intelligent manufacturing, the demand for compact cut to length machines in the market is also increasing. Many small and medium-sized enterprises hope to improve production efficiency and product quality by investing in modern metal cut to length machine. The compact cut to length line, with its unique design and functions, just meets this market demand.

1. Growing industrial demand

Against the background of rapid development of global manufacturing, the demand for metal products continues to rise, especially in industries such as construction, automobiles and home appliances. Compact cut to length machines have become indispensable equipment in these industries with their efficient production capacity and flexible application scenarios.

2. Continuous advancement of technology

With the advancement of science and technology, the design and manufacturing process of compact cut to length lines are also constantly improving. New materials and technical applications make the equipment more durable and precise, and can meet higher and higher production standards. This provides a broader space for the market expansion of compact cut to length machines.

The compact cut to length line is an efficient, flexible and highly automated metal sheet processing equipment suitable for factories of all sizes. Its advantages such as small footprint, simple operation and high production efficiency make it widely popular in the market. Compact cut to length machines are an ideal choice for companies that want to achieve efficient coil processing.

|

|

|

By investing in compact cut to length lines, companies can not only improve production efficiency, but also gain an advantage in the fierce market competition. Compact cut to length machines provide an attractive solution for both small and medium-sized enterprises that are just starting out and mature companies that want to increase their production capacity. As market demand continues to grow, the prospects for compact cut to length lines will be even brighter.