Recently, the BRUTE STEEL SLITTER team warmly welcomed the arrival of Indonesian customers and invited them to come to the factory to inspect the high speed cut to length line in person. This high speed cut to length machine was ordered by Indonesian customers from BRUTE STEEL SLITTER last year. After careful production, it was finally completed and ready for acceptance. This inspection is not only a recognition of BRUTE STEEL SLITTER manufacturing level, but also an important step to establish a closer cooperative relationship with Indonesian customers.

Before the inspection began, the BRUTE STEEL SLITTER team first took the Indonesian customers to the conference room for a detailed report. The main purpose of this meeting was to introduce the manufacturing process, technical details and related production capabilities of the high speed cut to length line to Indonesian customers. BRUTE STEEL SLITTER explained in detail the design concept, manufacturing process of the high speed cut to length machine and how to meet the specific needs of Indonesian customers.

|

Report content

Manufacturing process: Introduced every link from material selection to processing and assembly, showing the high standards and strict quality control adopted by BRUTE STEEL SLITTER in the manufacture of high speed cut to length lines. Technical details: Focused on the main technical parameters and innovative design of the high speed cut to length machine to ensure that Indonesian customers understand how this high speed cut to length line can provide efficient support for their production process. Production capacity: The types of metal materials and thickness range that the high speed cut to length machine can handle were emphasized to ensure that the Indonesian customers had a clear understanding of the applicability of the high speed cut to length line. Through this report, the Indonesian customers had a deeper understanding of BRUTE STEEL SLITTER manufacturing capabilities and professional level, and looked forward to the next high speed cut to length machine inspection. |

|

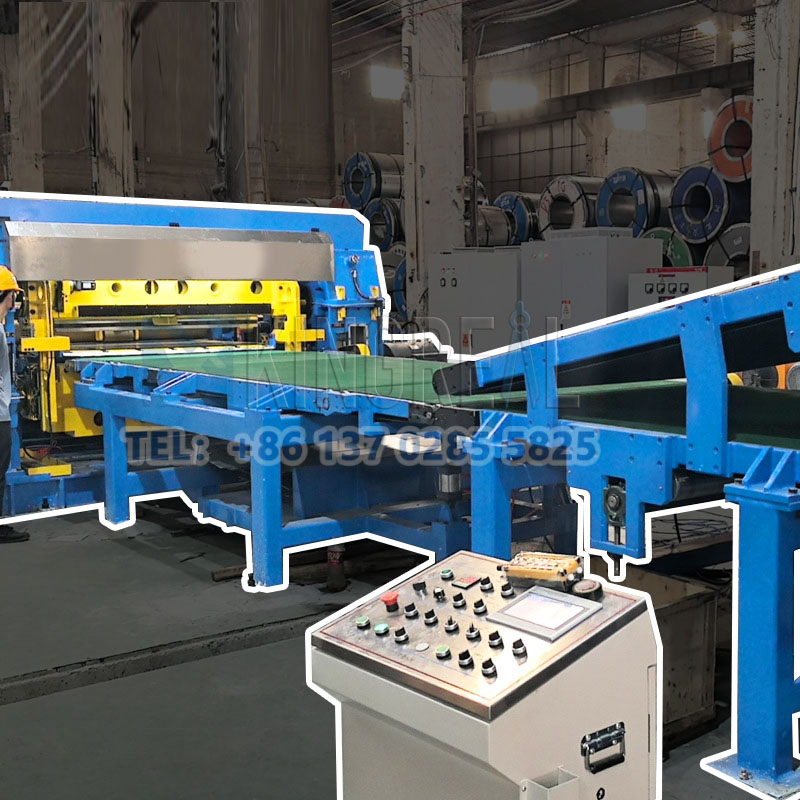

Then, the Indonesian customers entered BRUTE STEEL SLITTER workshop and began to conduct a detailed inspection of the high speed cut to length line. The Indonesian customers carefully inspected the appearance of each component of the high speed cut to length machine and measured the size of the high speed cut to length line with a ruler to ensure that all details were consistent with the plan at the time.

Component inspection

Decoiler for high speed cut to length machine: The Indonesian customers first inspected the decoiler, paying attention to its coil carrying capacity and the stability of uncoiling.

Leveler for high speed cut to length line: The design and function of the leveler also attracted the interest of the Indonesian customers, ensuring that the metal coils are in the best state of being sufficiently flat before shearing.

Cut to length machine: As the core component of the high speed cut to length line, the shearing accuracy and speed of the cut to length machine have received special attention. The Indonesian customers appreciated the design of the cut to length machine and believed that it could effectively improve production efficiency.

Waste collection device for high speed cut to length machine: The Indonesian customer also carefully inspected the waste collection device and confirmed that it can efficiently handle the waste generated during the production process.

Conveyor belt and stacker for high speed cut to length line: In particular, the Indonesian customer believes that the stacker is an important component for realizing the automation of the high speed cut to length machine, which can greatly reduce the labor intensity of workers.

|

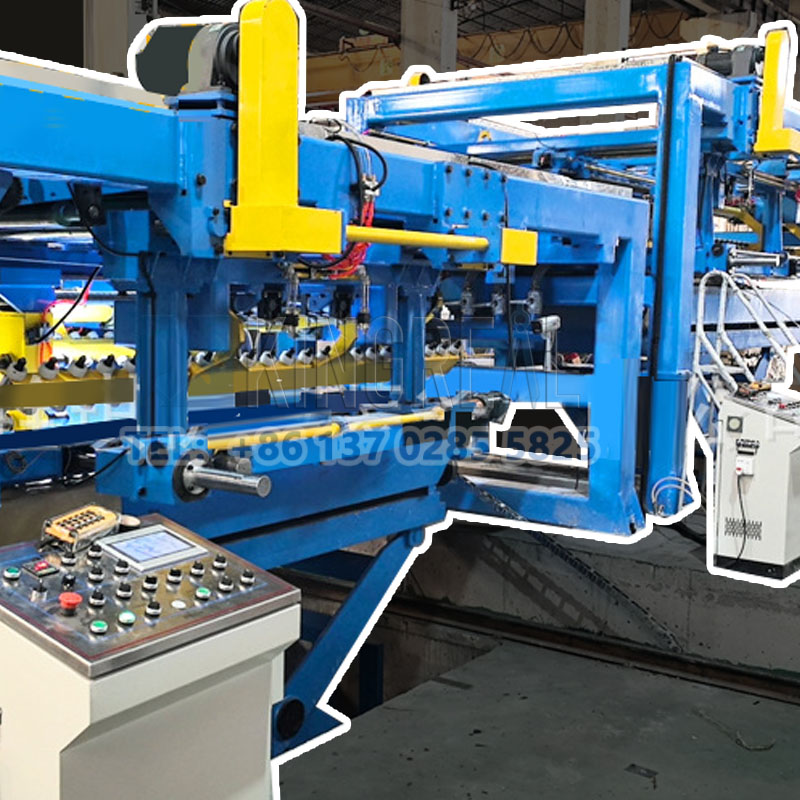

Trial process After completing the initial inspection, the Indonesian customer decided to test the high speed cut to length line. BRUTE STEEL SLITTER prepared metal coils for the Indonesian customer, started the machine, and observed the operation of the high speed cut to length machine.

Production speed The Indonesian customer praised the production speed of the high speed cut to length line, which can reach a maximum operating speed of 80m/min. This efficient shearing speed not only improves production efficiency, but also meets the needs of Indonesian customers for large-scale production. The Indonesian customer said that the design of the high speed cut to length machine fully meets their production goals and can greatly increase production capacity.

Automation features In addition, the intelligent stacker made the Indonesian customer feel particularly satisfied. The Indonesian customer pointed out that with the stacker, workers no longer need to stack materials manually, and the entire shearing process has become more efficient and automated. The intelligent design of the stacker ensures high speed and work quality, making the production process smoother.

|

|

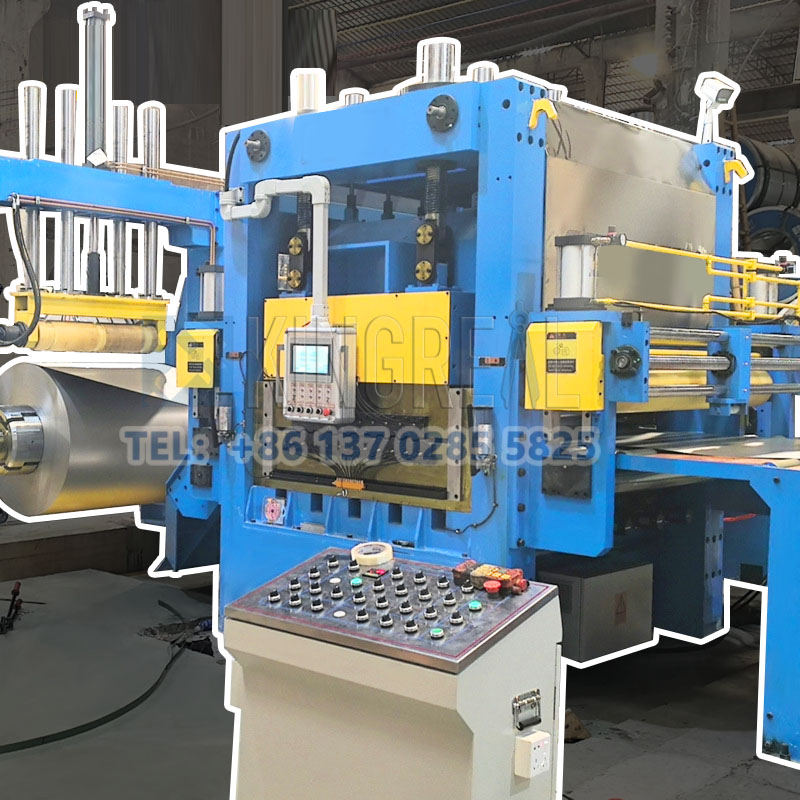

1. Flying shear system

The flying shear system is a highlight of this high speed cut to length line, which allows non-stopping during the shearing process. This design greatly improves the production speed of the high speed cut to length machine and reduces downtime, thereby improving the overall production efficiency. Traditional shearing methods often require stopping after each shearing, resulting in a waste of time. The flying shear system achieves efficient and continuous shearing by precisely controlling the movement of the tool, making the high speed cut to length line run more smoothly and suitable for high-load production needs.

2. Extensive metal material processing capabilities

This high speed cut to length machine can handle metal coils with a thickness range of 0.3-6mm, meeting the different production needs of Indonesian customers. Its processing capabilities cover a variety of metal materials, including: steel, stainless steel, carbon steel, galvanized steel, silicon steel, aluminum, copper alloy, etc. This wide range of processing capabilities enables the high speed cut to length line to flexibly respond to the production needs of different customers and is highly applicable.

3. Stable shearing quality

Through advanced technology and design, this high speed cut to length machine ensures the accuracy and quality of each shearing and can meet high-standard production requirements. BRUTE STEEL SLITTER uses high-precision sensors and control systems to monitor the shearing process in real time to ensure that the positioning and movement trajectory of the tool are accurate and correct. In addition, the surface quality of the sheared material is excellent, the edges are neat and burr-free, meeting the customer's stringent requirements for the final product.

|

|

|

|

After personally testing the high speed cut to length line, the Indonesian customers expressed great satisfaction with the high speed cut to length machine. They highly praised the various performances of the machine and look forward to the high speed cut to length line being packaged and shipped as soon as possible to Indonesia for installation. BRUTE STEEL SLITTER engineering team will also personally go to the Indonesian customer's factory to install the high speed cut to length machine and provide operation training for the workers to ensure that the customer can fully utilize all the functions of this high speed cut to length line. |

Through this machine inspection activity, BRUTE STEEL SLITTER cooperative relationship with Indonesian customers has been further consolidated. BRUTE STEEL SLITTER expects this high speed cut to length machine to run smoothly in the Indonesian customer's factory and bring them a more efficient shearing process. BRUTE STEEL SLITTER is always committed to providing customers with the best quality high speed cut to length lines and services, and looks forward to cooperating with more international customers in the future to create brilliance together.