|

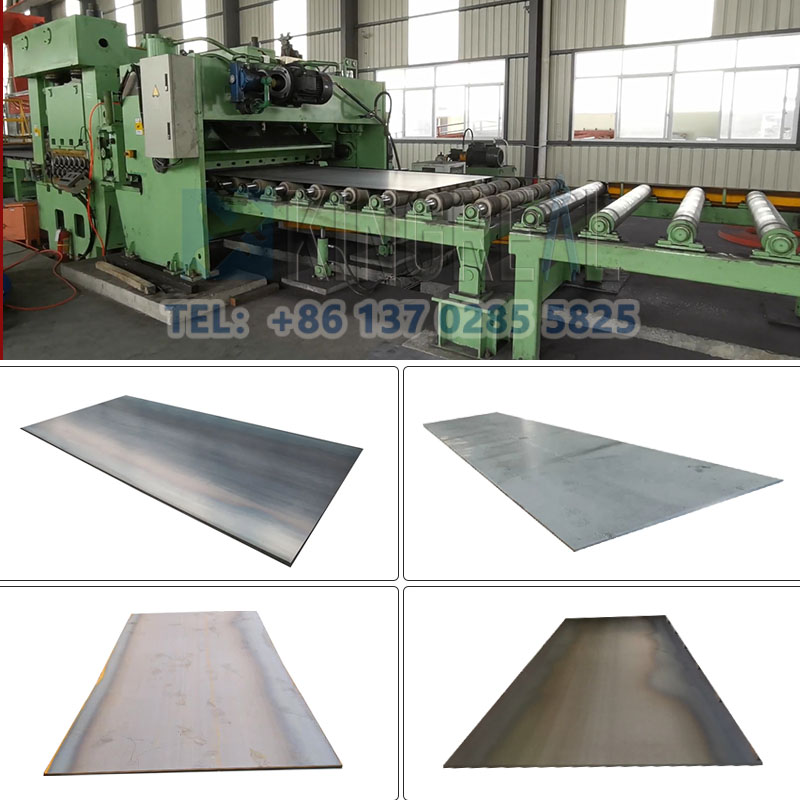

In modern manufacturing, heavy gauge cut to length lines, as the core equipment of metal plate processing production lines, are widely used in automobile manufacturing, home appliance production, building steel structures and other fields. It converts large metal coils into metal sheets of precise size through multi-process collaborative operation. With the continuous changes in market demand, especially the increasing demand for processing thick plate materials, BRUTE STEEL SLITTER continues to innovate in the design and development of heavy duty cut to length machines, and is committed to providing customers with more efficient and precise solutions.

With more than 20 years of rich experience, BRUTE STEEL SLITTER has established close cooperative relations with many countries such as Indonesia, Malaysia, Singapore, Russia, the United States, and Germany. Through in-depth exchanges with global customers and market research and analysis, our engineers found that many customers have clear requirements for the thickness of coils that heavy gauge cut to length lines can handle. These requirements depend on the customer's end use. Some customers need to cut thin metal coils, while others are in urgent need of heavy duty cut to length machines that can handle thick metal coils. However, existing heavy gauge cut to length lines still face many challenges in design and manufacturing.

After a long period of design, manufacturing and trial operation, BRUTE STEEL SLITTER has launched a heavy duty cut to length machine that meets customer needs, marking our technological innovation in this field. |

|

1.1 Challenges of design and manufacturing

|

From the production practice of heavy duty cut to length machines that have been put into production on the market, its production capacity and potential are very impressive, but the weak links often appear in the heating and finishing processes. Therefore, when designing a heavy gauge cut to length line, BRUTE STEEL SLITTER engineers must ensure that the capacity of the heating and finishing workshops can meet the requirements of the heavy duty cut to length machine.

The design of the heavy gauge cut to length line must meet the following requirements:

Production capacity matching: The design must ensure that it is compatible with the production capacity of the heavy duty cut to length machine.

Shearing force selection: The shearing force needs to be left with a surplus to meet the needs of shearing higher thickness coils in the future.

Shearing quality and precision: It must meet the requirements of the continuously improving thick plate shearing quality and steel plate dimensional accuracy.

Automation control requirements: In terms of the layout, equipment selection and structure of the heavy gauge cut to length line, the requirements of automation control must be met.

Surplus production capacity: Reserve surplus production capacity to cope with future expansion of production capacity and product range. |

|

1.2 Factors affecting unit shear resistance

|

In the operation of heavy duty cut to length machines, multiple factors affect the unit shear resistance, including:

1. Metal properties

The higher the strength limit of the metal material, the greater the shear resistance and the lower the plasticity. This means that the smaller the relative penetration depth during shearing, the earlier the metal fracture will occur. Therefore, the unit shear resistance is closely related to the strength and plasticity of the metal.

2. Shearing temperature

The high or low shearing temperature will also directly affect the unit shear resistance. The higher the temperature, the smaller the unit shear resistance, and the corresponding relative penetration depth during shearing is greater. This is of great significance to the design and operation of heavy gauge cut to length lines.

3. Deformation depth

During hot shearing, the unit shear resistance increases with the increase of deformation speed. In the case of cold shearing, the effect of shearing speed on unit shear resistance is relatively small and can usually be ignored.

4. Shear blade lateral clearance

The size of the shear blade lateral clearance will affect the stress condition during shearing. When the lateral clearance gradually increases, the stress condition will occur in sequence from compression → shearing → bending. Reasonable selection and maintenance of the size of the shear blade lateral clearance is crucial for the correct use of the heavy duty cut to length machine. Experiments show that as the relative lateral clearance of the shear blade increases, the unit shear resistance decreases, and the corresponding relative penetration depth at fracture increases. |

|

1.3 Cooling of the cooling bed

|

In the production of the heavy gauge cut to length line, cooling of the cooling bed is also an important link. After the hot straightening steel plate is marked by the hot steel plate marking device, it enters the walking beam cooling bed. At this time, the temperature of the steel plate is generally around 600-700℃, and the temperature of the extra thick plate may reach above 850℃.

At the cooling bed, the logistics of steel plates with a thickness of 5-150mm will be divided into the following flow directions:

Extra thick plate cooling bed: Steel plates with a thickness greater than 50mm enter the No.3 cooling bed for cooling, and then are sent to the extra thick plate processing area, cut to size using a flame cutting machine, and finally stored.

Ordinary cooling bed: Steel plates with a thickness of less than 50mm enter No.1 and No.2 cooling beds for cooling. Due to the different configurations of the two cooling beds, in order to improve the utilization rate of the cooling beds, thicker steel plates should be arranged to be cooled on No.1 cooling bed as much as possible.

On the cooling bed, steel plates are discharged piece by piece, usually in the form of 1 row or multiple rows (up to 4 rows). The lateral spacing on the cooling bed is generally 100-300mm; for the extra-thick plate cooling bed, the discharge spacing of the steel plates should be gradually increased with the increase of thickness, so as to control the unit load weight within the limit allowed by the cooling bed. |

|

BRUTE STEEL SLITTER heavy gauge cut to length line has many significant features that make it stand out in the market:

(1)Versatile Thickness Adaptability

Capable of processing metal coils within 6-20mm thickness parameters, this system addresses diverse industrial requirements through its flexible material handling capabilities.

(2)High-Efficiency Shearing Architecture

Equipped with advanced flying shear technology, the system operates continuously at peak speeds of 80m/min, substantially elevating throughput rates while maintaining material integrity.

(3)Intelligent Automation Integration

Full PLC-based control architecture ensures operational reliability and process consistency, significantly reducing human-factor errors through automated workflow management.

(4)Precision Measurement Protocol

Integrated real-time monitoring system automatically verifies and displays cutting dimensions and batch counts, guaranteeing ±0.1mm dimensional accuracy across production cycles.

(5)Comprehensive Safety Protocols

Dual safety mechanisms including emergency stop activation and multi-stage alarm systems ensure OSHA-compliant operations while minimizing workplace incidents.

(6)Market Responsive Solution

Against the backdrop of escalating demands for precision-thickened metal materials, BRUTE STEEL SLITTER R&D team has engineered an industry-leading heavy gauge cut to length line that synergizes technical excellence with commercial viability. Our solution demonstrates measurable ROI through:

|

30% productivity enhancement via continuous operation design |

|

25% operational cost reduction from automated quality control |

|

99.8% process reliability achieved through redundant safety systems |

|

|

|

As pioneers in metal processing solutions, we maintain our industry primacy through:

✓ Bi-annual hydraulic system upgrades

✓ AI-driven predictive maintenance integration

✓ Customizable parameter modules for niche applications

For technical consultation or customized configuration inquiries, our engineering team stands ready to demonstrate how BRUTE STEEL SLITTER heavy duty cut to length machines can optimize your production matrix. Contact us to schedule a deep-dive technical presentation and discover competitive advantages tailored to your metalworking operations.