|

Heavy gauge slitting lines can slit metal coils with a thickness of 6-16mm, and the narrow strips separated in this way are suitable for automobile manufacturing industry, construction industry, home appliance industry, etc. Heavy gauge coil slitting machines are suitable for longitudinal shearing of metal strips and rewinding the slit narrow strips into coils. Its core lies in a set of rotating blades. These blades cut the material entering the machine from top to bottom by rotating at high speed. |

|

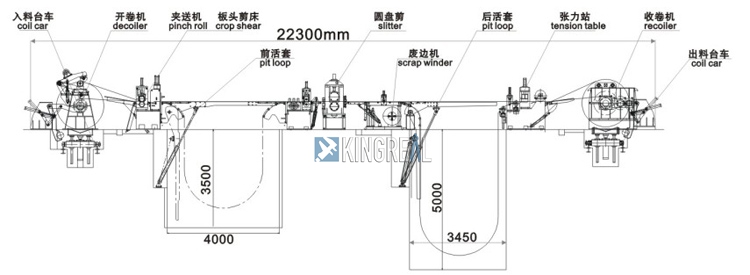

Workflow of heavy gauge coil slitting machine

Trolley for coil loading → Hydraulic decoiler →2 rolls feeding and 3 rolls leveling → Loop bridge → High precision shearing machine → Side scrap recoiling →Pre-seperator and damping tension machine → Rewinding

Main components of heavy gauge slitting line

|

(1)Precision blades for heavy gauge slitting line. BRUTE STEEL SLITTER heavy gauge coil slitting machine achieves precise cutting of materials through the longitudinal bite of upper and lower knives. The blades are made of high-quality tool steels and high-alloy mold steels such as T10, H13K, HM-3, 6Crw2Si, Cr12WmoV, LD, H13, and W18Cr4V. They have the characteristics of wear resistance and high cut flatness, and can adapt to the processing needs of 0.1mm ultra-thin plates to 10mm thick steel plates. The manufacturing process of precision blades is very strict, which can effectively improve the cutting accuracy. And because the blades are sharp and uniform, they can reduce burrs and deformation during cutting and improve the surface quality of the finished product. It is worth mentioning that high-quality materials and processes make precision blades more wear-resistant, extend service life, and reduce replacement frequency and cost. |

|

|

(2)Recoiler for heavy gauge coil slitting machine. After the slitting is completed, the narrow strips are rolled up by an automatic recoiler to facilitate long-distance transportation and subsequent processing. |

|

|

(3)Monitoring system for heavy gauge slitting line. The BRUTE STEEL SLITTER heavy gauge coil slitting machine is equipped with a high-definition monitoring system, which can observe the operation of each component of the heavy gauge slitting line in real time, facilitate monitoring, and do not require workers to stand next to each component. This makes it easier to detect faults or abnormal conditions and saves manpower. |

|

|

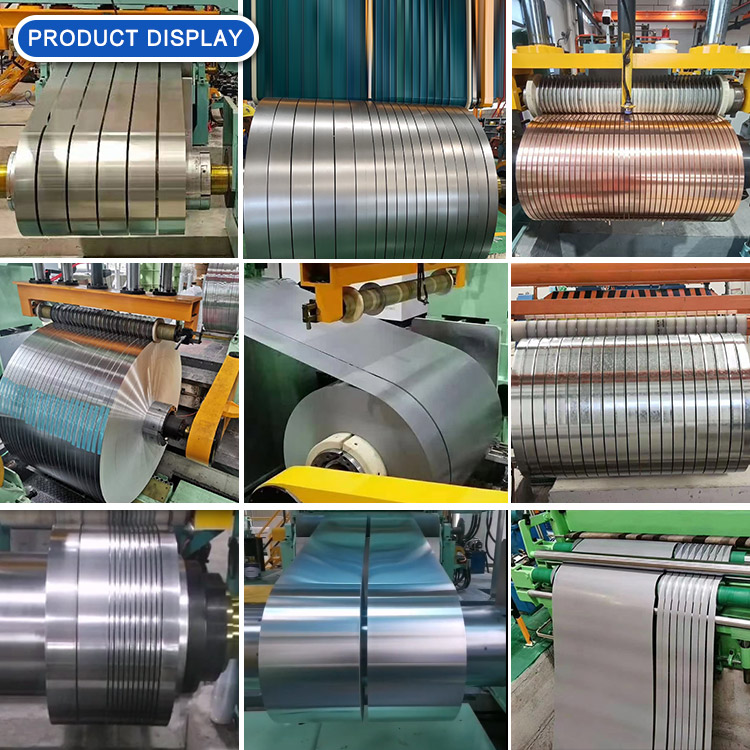

(1) Highly adaptable heavy gauge slitting line. This heavy gauge coil slitting machine can process a variety of metal materials such as silicon steel sheets, aluminum strips, copper, stainless steel plates, galvanized plates, etc. to meet the diverse needs of customers.

(2) Can cut out multiple narrow strips. According to customer needs, BRUTE STEEL SLITTER heavy gauge slitting line can design the number of narrow strips to be cut. Up to 40 narrow strips can be cut at one time! This efficient cutting ability greatly improves production efficiency and reduces processing time.

(3) Customized heavy gauge coil slitting machine. BRUTE STEEL SLITTER will customize the heavy gauge slitting line according to actual production needs, so the performance of the heavy gauge coil slitting machines sold is not exactly the same. This customized service not only meets the specific needs of customers, but also improves production efficiency. For example, BRUTE STEEL SLITTER engineers once designed a heavy gauge slitting line with a protective shield according to customer needs, which can better protect the safety of workers and reduce the probability of safety hazards during production; in addition, the heavy gauge coil slitting machine can also be equipped with a laminating device to ensure that there are no scratches on the surface of the narrow strips, further improving product quality.

(4) Fully automated heavy gauge slitting line. This heavy gauge coil slitting machine consists of multiple automated components, which saves human resources to the greatest extent. The operator only needs to enter the relevant parameters on the control panel and turn on the machine, and the heavy gauge slitting line will automatically carry out processes such as unwinding, leveling, slitting and rewinding. This fully automated design not only improves production efficiency, but also reduces the possibility of human operation errors, making the production process more stable and reliable. |

|

|

The narrow strips cut by the heavy gauge slitting line are widely used in many industries. The following are some of the main areas:

(1) Automobile manufacturing In the automobile manufacturing industry, metal narrow strips are widely used in the production of body structures, chassis and other key components. Precision cutting can ensure the dimensional consistency and strength of each component, and improve the safety and performance of the whole vehicle.

(2) Construction industry The construction industry requires a large amount of metal materials for structural support and decoration. The heavy gauge coil slitting machine can provide standard steel to meet the needs of different construction projects.

(3) Home appliance manufacturing In the home appliance industry, metal narrow strips are used to make shells, brackets and internal structural parts. Fine cutting and high-quality surface treatment ensure the beauty and durability of the finished product.

(4) Electronics Industry In electronic products, narrow metal strips are often used in the manufacture of connectors, brackets and other components, which require high precision and good conductivity.

(5) Machining The machining industry requires metal strips of various specifications as raw materials. The heavy gauge slitting line can quickly cut and supply a variety of materials to meet the needs of the production line. |

|