BRUTE STEEL SLITTER has provided personalized automatic coil slitting machine manufacturing solutions for customers in many countries around the world. BRUTE STEEL SLITTER is good at combining customer drawings and adjusting parameter performance by equipping different components after full communication with customers to form an automatic coil slitting line dedicated to customers. In this article, BRUTE STEEL SLITTER selected five classic automatic coil slitting machine success cases to share with you. If you are interested in a certain automatic coil slitting line and want to get more information about the machine, please contact BRUTE STEEL SLITTER in time!

|

Customer Demand Overview

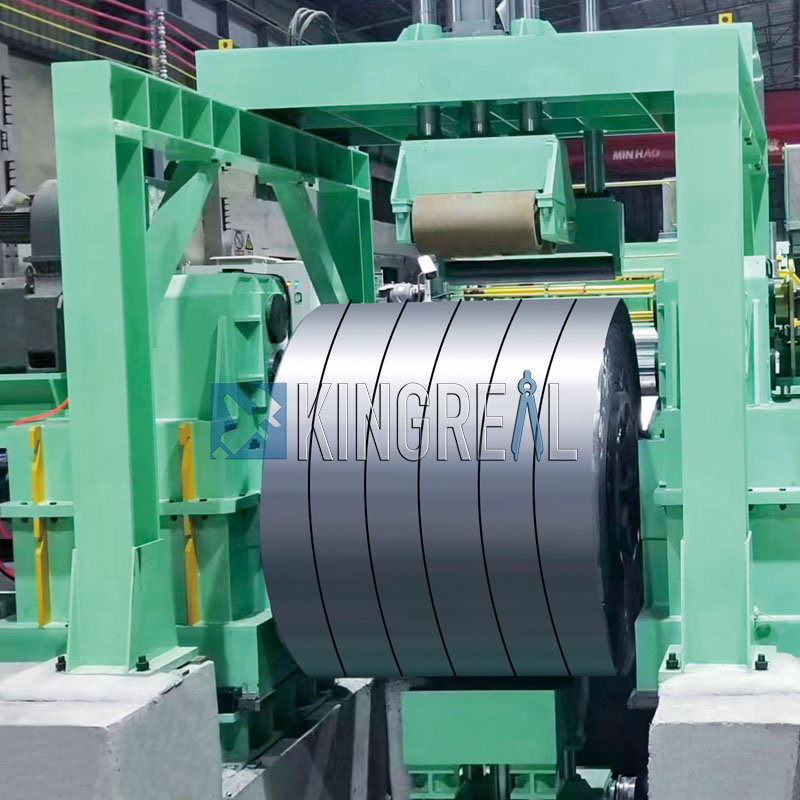

Albanian customers focus on the steel industry. Faced with the growing market demand for thick steel narrow strips, they are looking for a fully automatic coil slitting machine that can effectively meet their production needs. In the communication with BRUTE STEEL SLITTER, the Albanian customer clearly stated that he hoped that the automatic coil slitting line could handle metal coils with a thickness of 6-16mm and reduce labor costs while improving production efficiency. |

|

Machine Design Process

Responding to Albanian consumer demand, BRUTE STEEL SLITTER engineering team carefully assessed the client's particular needs including coil width, coil thickness, and output volume. Engineers created a heavy gauge slitting machine following thorough awareness of the Albanian customer's manufacturing method; this heavy gauge slitting machine can not only efficiently slit but also enable intelligent control throughout the production process.

Engineers concentrated on the heavy gauge slitting machine’s stability and ease of operation during the design phase to guarantee its ability to operate under heavy loads. Simultaneously, the machine's control system uses cutting-edge technology that may monitor the slitting process in real time to guarantee that every link of production satisfies the desired criteria.

Advantages of Heavy Gauge Slitting Machine

(1)The heavy gauge slitting machine can accomplish completely automated output, significantly lower manual intervention, and increase production efficiency.

(2)Equipped with a unique recoiler, it can automatically wind the narrow strips, prevent errors brought on by manual labor, and guarantee the finished product's neatness.

|

|

|

|

Customer demand overview

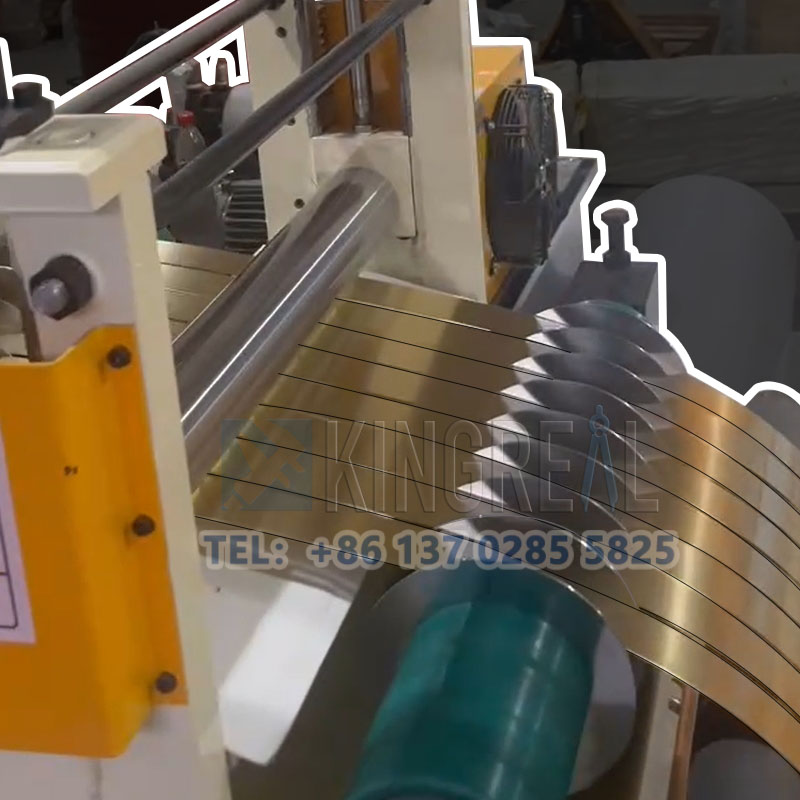

Tunisian customers have extremely high requirements for the appearance of the product, especially the neatness of the surface of the narrow strip. The customer hopes to produce a automatic coil slitting line with no scratches on the surface to ensure that the quality of the final product can meet market demand. |

|

Machine Design Process

Responding to the particular needs of Tunisian clients, BRUTE STEEL SLITTER engineers suggested to fit the stainless steel coil slitting machine with a laminating device. To guard against scratches during cutting, the instrument coats the coil's surface with a protective coating. Throughout the design phase, the engineers maintained close contact with the Tunisian client to guarantee that the composition and thickness of the laminating film fit the aesthetic criteria of the product.

Moreover, the engineers incorporated cutting-edge technology in the stainless steel coil slitting machine's cutting mechanism to guarantee that each cut meets great accuracy and lessens mistakes. Such a design helps the stainless steel coil slitting machine to much enhance the surface quality of the item in addition to boost the cutting efficiency.

Advantages of Stainless Steel Coil Slitting Machine with Laminating

(1)Advanced cutting technology and control mechanism in the stainless steel coil slitting machine guarantee cutting precision that satisfies industry norms and lowers final product waste.

(2)The stainless steel coil slitting machine may cut continuously and rapidly, increasing output efficiency and fulfilling the Tunisian customer's high output requirements.

|

|

|

|

Overview of Customer Demand

American customers attach great importance to the safety of workers during the production process. Therefore, in the design of the copper coil slitting machine, it is required that protective devices must be installed to ensure the safety of workers during operation. |

|

Machine Design Process

Alongside thinking about the automatic coil slitting machine’s cutting capacity, the BRUTE STEEL SLITTER engineering team also deliberately built the copper coil slitting machine with a protective shield. Aside from meeting the local safety codes in the United States, this design successfully avoids unintentional injuries that could result from the machine's operation. Furthermore increasing the safety of the machine, the engineers have included a realtime monitoring system that will automatically turn off under unusual circumstances.

The designers made sure the copper coil slitting machine may adjust to the cutting demands of copper plates of varied materials and thicknesses, therefore increasing its adaptability and flexibility.

Advantages of Copper Coil Slitting Machine with Protective Shield

(1)The copper coil slitting machine can satisfy a range of manufacturing demands by cutting plates of several materials and thicknesses; it has great flexibility.

(2)Humanized design ensures worker safety and comfort by providing a user-friendly, simple-to-maintain operating interface.

|

|

|

|

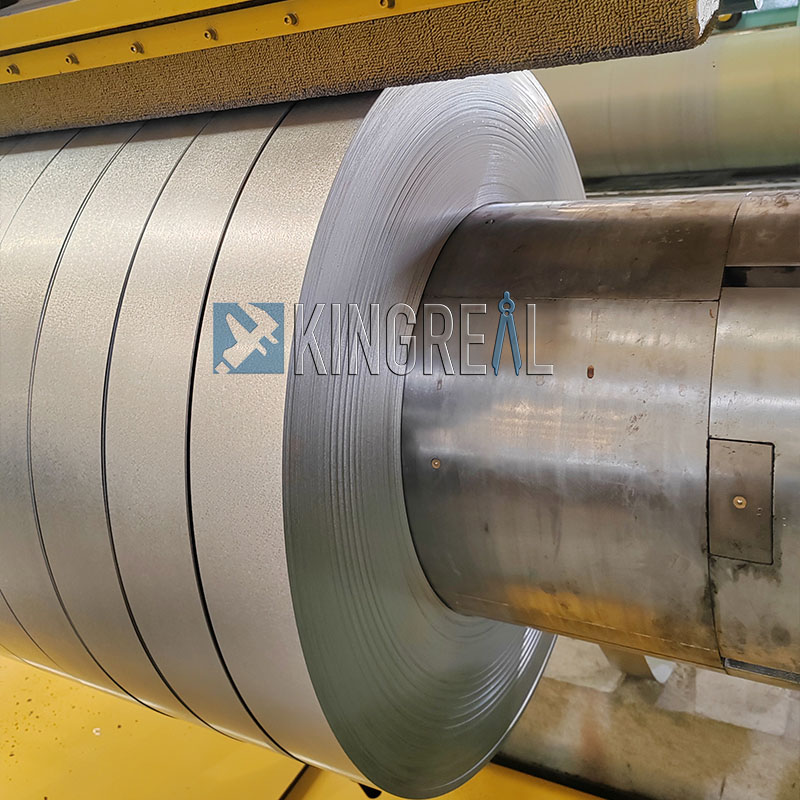

Customer Demand Overview

The Australian customer's production scale and output are very large. They hope to obtain a high speed coil slitting machine that can run at high speed to meet the growing market demand. |

|

Machine Design Process

After confirming the metal material and thickness that the customer needs to process, BRUTE STEEL SLITTER engineers finally designed an automatic coil slitting line with a maximum running speed of 230m/min. During the design process, the engineers fully considered the stability and durability of the high speed coil slitting machine to ensure that it can maintain efficient cutting quality at high speeds.

In addition, the design of the high speed coil slitting machine also has a flexible adjustment function, which can easily adjust the running speed of the automatic coil slitting machine according to actual production needs, ensuring that customers can efficiently complete various production tasks.

Advantages of High Speed Coil Slitting Line

(1)The high speed coil slitting machine can cut out up to 40 narrow strips at the same time, greatly improving production efficiency and meeting customers' high production needs.

(2)The running speed of the automatic coil slitting machine can be adjusted according to actual production needs to ensure optimal performance under different production conditions.

|

|

|

|

Customer Demand Overview

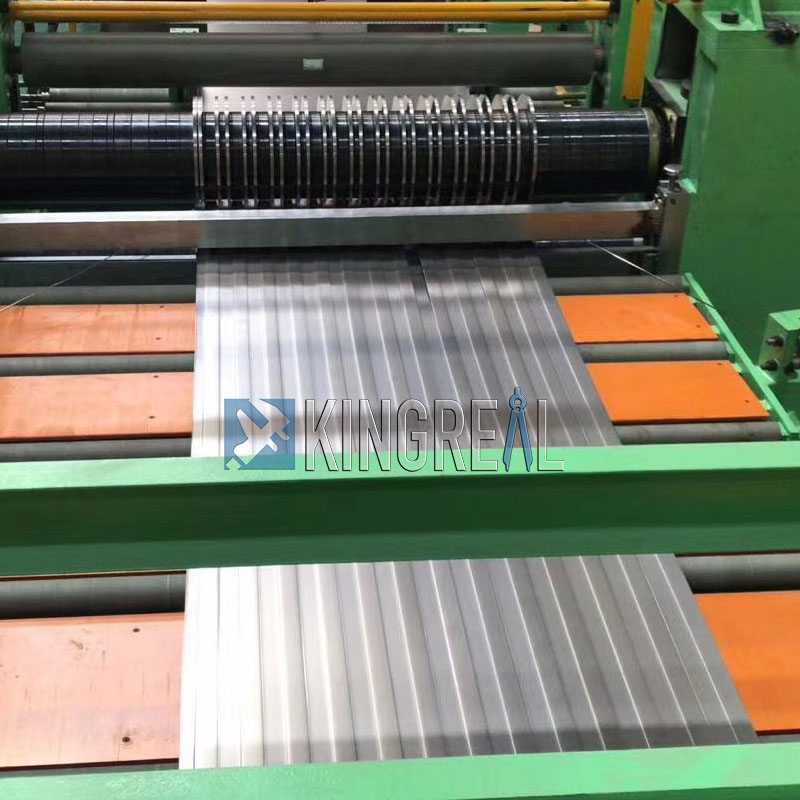

Danish customers need to face a variety of materials in processing, including stainless steel, copper, steel, PPGI, etc., so they hope to obtain a metal coil slitting machine that can adapt to a variety of different materials. |

|

Machine Design Process

In response to the diverse needs of Danish customers, BRUTE STEEL SLITTER engineering team confirmed the thickness of each metal material that the customer needs to process to ensure that the designed metal coil slitting machine can adapt to all these materials. During the design process, engineers took into account the flexibility and adjustability of the automatic coil slitting machine to ensure that customers can easily cope with the processing needs of different materials in actual operation.

In addition, the cutting system of the metal coil slitting machine has also been carefully designed to ensure that the cutting edge is smooth and burr-free, which improves the quality of the finished product.

Advantages of Metal Coil Slitting Machine

(1)The metal coil slitting machine design allows the slitting width to be adjusted according to different production needs, suitable for diversified production.

(2)The cutting process ensures that the finished product has a smooth edge and no burrs, which improves the market competitiveness of the product.

|

|

|