|

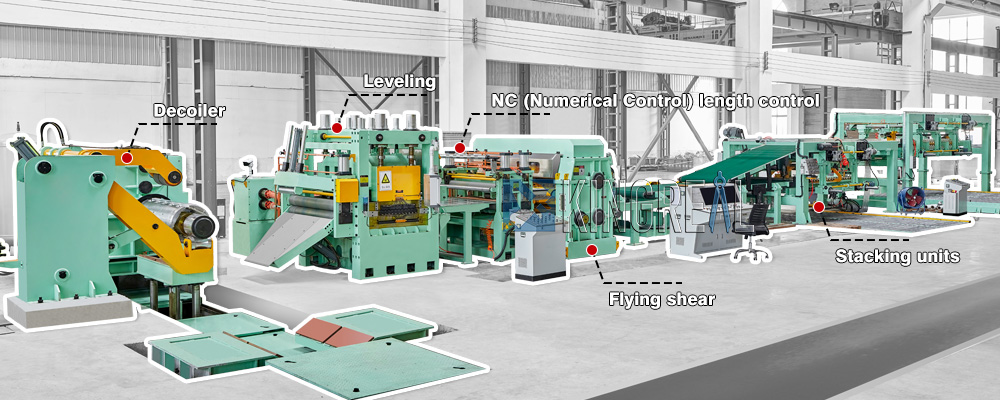

The rotary shearing cut to length machine is mainly used for precision leveling and accurate cutting of metal coils such as copper, stainless steel, aluminum, and iron. The unique advantage of this rotary shearing cut to length line is that it can cut without stopping the machine, avoiding the tiny indentations caused by stopping the rotary shearing cut to length machine for cutting. It is suitable for short-cut length products such as high-precision aluminum plates and mirror stainless steel plates.

The rotary shearing cut to length line consists of three parts: widening, leveling and transverse cutting of the fixed-length metal strip, and adopts a suitable blanking system. Compared with the fixed shearing cut to length line, the rotary shearing cut to length line achieves non-stop shearing, faster speed, higher precision and better surface protection. |

|

The rotary shearing cut to length machine is a continuous production line, and the cutting is completed by a double-eccentric rotary cutter. Today's double-eccentric shearing machines work differently. The upper and lower shear blade beams perform eccentric motion, which is similar to rotational motion, rather than alternating forward and reverse rotation, so it is very stable. During the entire eccentric motion, the blade remains in a vertical position, which helps to minimize burrs. The strip does not need to be accelerated and decelerated for each cut, which reduces the risk of strip slippage.

The shear frame itself remains stationary, so wear is reduced, and the shear can be moved quickly within the frame. Depending on the rotary shearing cut to length line design, the shear can run continuously at strip speeds of up to 330 feet per minute (100 meters per minute).

In a continuous eccentric rotary shearing cut to length machine, the bottleneck is not the shearing operation, but the maximum processing speed of the stacker or the capacity of the packaging line. Because the material does not stop for cutting, the average strip speed can usually be increased, thereby increasing the overall output of the rotary shearing cut to length line.

|

|

Item |

Qty |

| 1 |

Loading Station |

1 |

| 2 |

Loading Car |

1 |

| 3 |

Decoiler |

1 |

| 4 |

Precise Leveling Machine (19 Rollers) |

1 |

| 5 |

Servo Feeding Device (Include Laminating Device) |

1 |

| 6 |

Rotary High Speed fly Cutter |

1 |

| 7 |

Three Stages Belt Conveyor |

1 |

| 8 |

1st Automatic sheets Gathering Machine & Upper Belt Conveyor |

1 |

| 9 |

2nd Automatic Gathering Machine |

1 |

| 10 |

Hydraulic System |

1 |

| 11 |

Pneumatic System |

1 |

| 12 |

Lubricating System |

1 |

| 13 |

Electrical System |

1 |

(1)High-Efficiency, Precise Cutting

Rotary shearing cut to length line is engineered to handle a wide range of materials, with a thickness capacity from 0.3mm to 3.0mm and a maximum width of 1600mm.

Rotary Shear Technology: Enables continuous feeding during cutting, reducing downtime and improve production speed.

Adjustable Setting: Easily modify cutting lengths and feeding speeds according to production requirements.

High Precision: Even at high speeds, the rotary shearing cut to length machine maintains cutting accuracy, minimizing material waste.

(2)Rotary Shear Head for rotary shearing cut to length machine

The advanced Rotary Shear Head, equipped with a high-speed double crank rotation, ensures uninterrupted plate tracking.

(3)Front stacking device for rotary shearing cut to length line

The objective is to stack and pack processed sheets in a way that avoids collisions between sheets.

(4)Back-stacking device for rotary shearing cut to length line

The long steel pieces cut by the shearing machine are sent to the machine through the conveyor, collected neatly by the combination of air pressure and hydraulic pressure, and then transported out through the discharging roller.

|

|

|

BRUTE STEEL SLITTER is a leading metal cut to length line manufacturer in China, with products including rotary shearing cut to length machine, flying shearing cut to length line, fixed shearing cut to length line, light gauge cut to length line, medium gauge cut to length line, heavy gauge cut to length line, etc.

BRUTE STEEL SLITTER metal cut to length lines are designed and manufactured with the highest precision, efficiency and performance, suitable for processing various metal materials, serving metal service centers, steel mills, automotive industry, home appliance industry and many other industries around the world. BRUTE STEEL SLITTER can provide a variety of high speed cut to length lines depending on material size, thickness and production capacity.

If you have any questions about BRUTE STEEL SLITTER rotary shearing cut to length machines, please feel free to contact us.