|

The mini coil slitting line is a small equipment used for slitting small coils. The mini coil slitting machine mainly includes: hydraulic decoiler, slitting machine, conveyor, hydraulic recoiler, or used in conjunction with a roll forming machine.

This mini coil slitting line is used to slitting the coil into the required size, and then roll forming into the specified shape, while the winder winds up the waste. Using this specially designed mini coil slitting machine, BRUTE STEEL SLITTER can save a lot of coil processing costs, and it is highly efficient and energy-saving. Moreover, this mini coil slitting line has an affordable design and is easy to load and operate. |

|

|

Item |

Parameters |

|

Coil thickness (mm) |

0.4-1 |

|

No. of slitters |

Tailor-made |

|

Roll stand |

18 |

|

Main power (Kw) |

7.5 |

|

Main shaft (mm) |

Ø70 |

|

Cutter material |

Cr12 |

|

Cutting accuracy |

10±2mm |

|

Hydraulic station power (Kw) |

5.5 |

|

Control system |

PLC |

|

1. Hydraulic Decoiler for mini coil slitting machine Hydraulic expand and shrink to tight the inner hole of steel coils. Inner diameter:Ф480-520,width:500 mm 10T with simple supporting stand, without coil car Fixed the coil to active uncoil, with brake. The hydraulic expand and shrink decoiler is driven by hydraulic, to tight the inner hole of steel coil. |

|

|

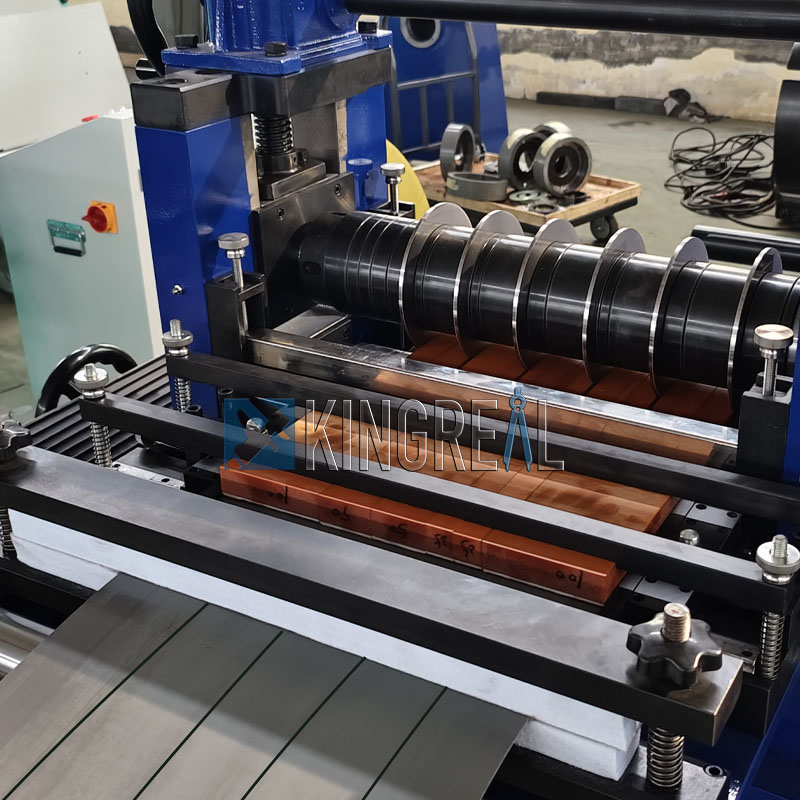

2.Slitting Machine for mini coil slitting line Specification of blades:Ф340x200x15:material: Cr12 Electric motor: 7.5Kw frequency conversion control motor to control the speed. Control mode is frequency control. Reducer : cycloidal reducer It equips the side guide device, to achieve positioning strip and stop the jumping of strip. Improve the accuracy of slitting. it can shear actively or passively. To achieve different strip thickness accuracy requirements of slitting. |

|

|

3.Tension Stand for mini coil slitting machine The frame welded by steel plates.Consist of base, pre-dividing shaft, bracket, press shaft, hydraulic damp device and hydraulic shaft lifting the press down device. Supporting slices, spacers and etc. Function: it also have the side guide device for finished strips and prevent them from jumping and improve the recoiler quality. To establishing a stretching force with recoiler, to make sure the even quality and tight of steel coils after recoiling. |

|

|

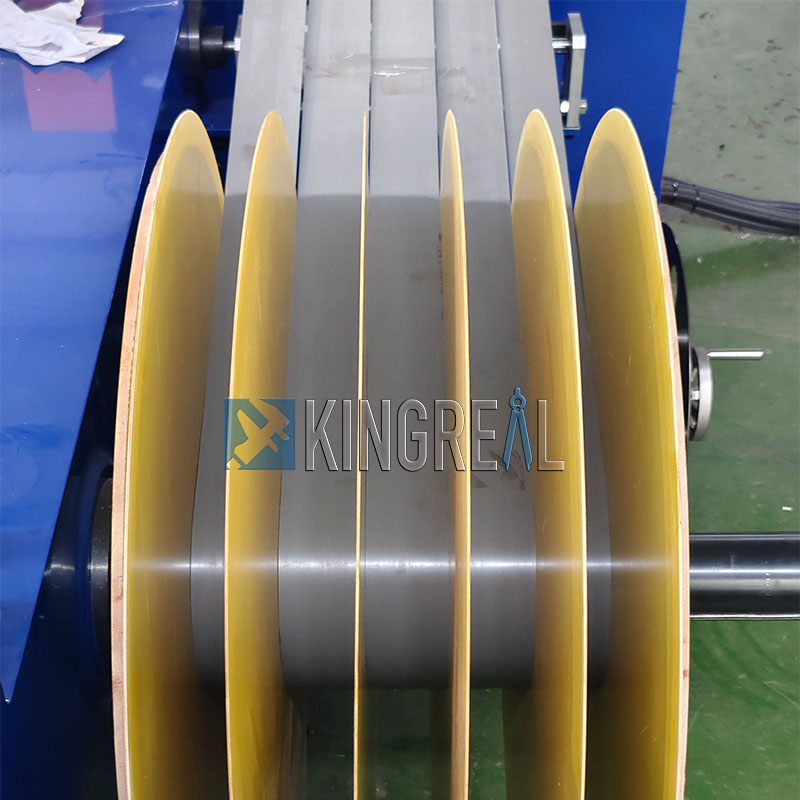

4.Recoiler for mini coil slitting line Structure:hydraulic expand and shrink model Capacity:10T with simple supporting stand Motor: 7.5KW Overall steel plate cantilever structure Function: It works with the finished steel strips after first pre-dividing and second dividing to insure the even and tight quality of recoiler. Recoiling tension and speed are adjustable |

|

1.Accurate Knife Clearance

Mini coil slitting line with high accuracy could maintain stable knife gap.

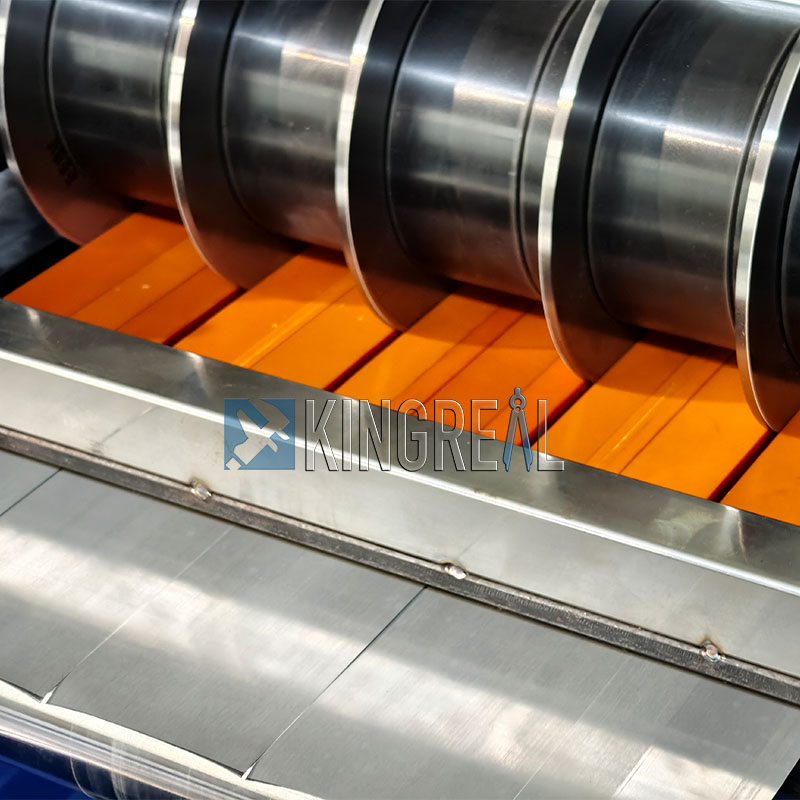

2.Mounting With Bakelite Fingers

To use Bakelite fingers could reach easily mounting and increase efficient.

3.Mounting With PU Stripper Rings

Using Stripper Rings could decrease the surface damage which happened when slitting.

4.Recoiling With Material Tray

6mm width recoiling Nickle alloy strips with Material Tray.

1.Small footprint

The compact design of the mini coil slitting line gives it a clear advantage in terms of floor space. Many small and medium-sized enterprises or start-ups face the problem of limited space when setting up production lines. Traditional large coil slitting machines often require a large working space, and the mini coil slitting line layout is complex, making it difficult to effectively use the space. The design concept of the mini coil slitting machine is to save space to the maximum extent while maintaining efficient production capacity.

For example, a standard mini coil slitting line only takes up about ten square meters of space to complete the cutting tasks of a variety of coils. For many start-ups, this can achieve production flexibility in a limited space and avoid the dilemma of having to give up potential orders due to insufficient space. In addition, the compact design also makes the handling and installation of the mini coil slitting machine easier, and the company can adjust the production layout at any time according to actual needs, thereby improving production efficiency.

2. Low cost of capital

One more important benefit of the mini coil slitting machine is that it greatly lowers the investment cost. The cost of mini coil slitting lines is more reasonable and appropriate for small and mid-sized businesses and startups than it is for conventional large coil slitting machines. Companies with limited resources particularly need to control expenses while guaranteeing production capacity, therefore this is especially crucial for them.

Investing in a mini coil slitting machine helps businesses to cut maintenance and operating expenses as well as save equipment purchasing fees. Because the mini coil slitting machine is meant to be more effective and consumes rather little energy, the company's total operating expenses are significantly lowered. The great performance of the mini coil slitting line further implies that companies may reclaim their investment swiftly, therefore raising fund turnover efficiency.

3. Easy control

Friendly operating interface, simple use, and intuitive design make the mini coil slitting line very accessible. In a brief period, even unskilled operators without great expertise can pick up the fundamentals of the mini coil slitting machine. This helps small and medium-sized businesses save time, cut training expenses, and boost production efficiency.

The mini coil slitting line's maintenance is also simple; the operator may easily conduct daily inspections and upkeep to guarantee the finest condition of the mini coil slitting line at all times. Taking into account the real needs of users, the mini coil slitting line simplifies the operating process, avoids complicated settings and corrections, and smooths the manufacturing process.

|

|

|

4. Low energy use with great efficiency

The mini coil slitting machine uses an innovative control system that guarantees effective performance while lowering energy usage. Modern companies are increasingly focused on environmental protection and sustainable development in their operations, and the mini coil slitting line quite fits this trend. Its efficient cutting capacity and optimized energy consumption management not only improve production efficiency but also lessen the impact on the environment.

The mini coil slitting machine, for instance, can give accurate tool control during the cutting process, therefore lowering material waste. This lowers company operating expenses in addition to raising material utilization rates. By doing so, businesses may guarantee production efficiency and so more proactively react to environmental protection needs and strengthen their social accountability.

5. Cutting solutions adaptable

Supporting customized cutting solutions, the mini coil slitting line can flexibly change the cutting width and thickness depending on the various needs of consumers. This adaptability lets businesses satisfy the tailored needs of consumers as well as react swiftly to changes in the market.

For instance, some sectors could need coils of a certain thickness or width, which the adjustable design of the mini coil slitting machine can easily accomplish. Businesses don't have to spend money on several equipment; only one tiny coil slitting line can satisfy several market demands, therefore lowering the danger of equipment investment.