Metal cut to length machine is an automated production equipment designed for metal sheet processing. It is mainly used to cut large coils of metal materials (such as steel coils, aluminum coils, stainless steel coils, etc.) into plates of fixed length. Cut to length line is widely used in many industries such as automobile manufacturing, home appliance production, building materials, aerospace, etc. Its high efficiency and precision provide important support for modern industrial production.

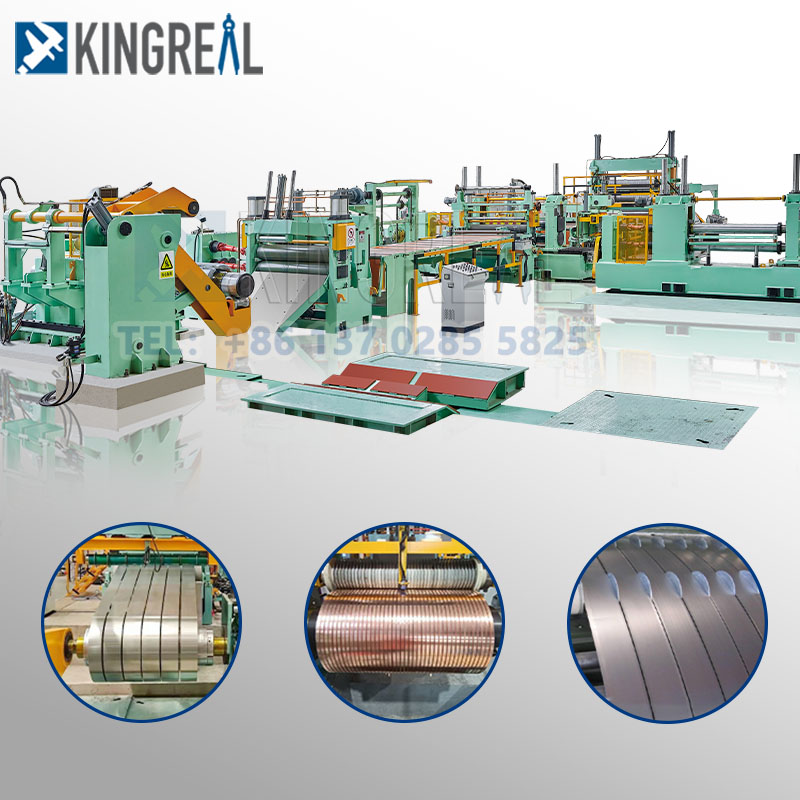

Workflow of cut to length line:

Uncoiling: Fix the metal coil on the decoiler and send it to the leveling machine after uncoiling.

Leveling: Correct the bending or uneven parts of the coil through the leveling machine to ensure the flatness of the plate.

Shearing: Cut the metal sheet through the cut to length machine according to the preset length. The shearing method mainly includes mechanical shearing and hydraulic shearing. The specific choice depends on the material thickness and production requirements.

Conveying: The sheared sheet is moved to the stacking area through the conveying system.

Stacking: The cut sheets are neatly stacked for subsequent processing or transportation.

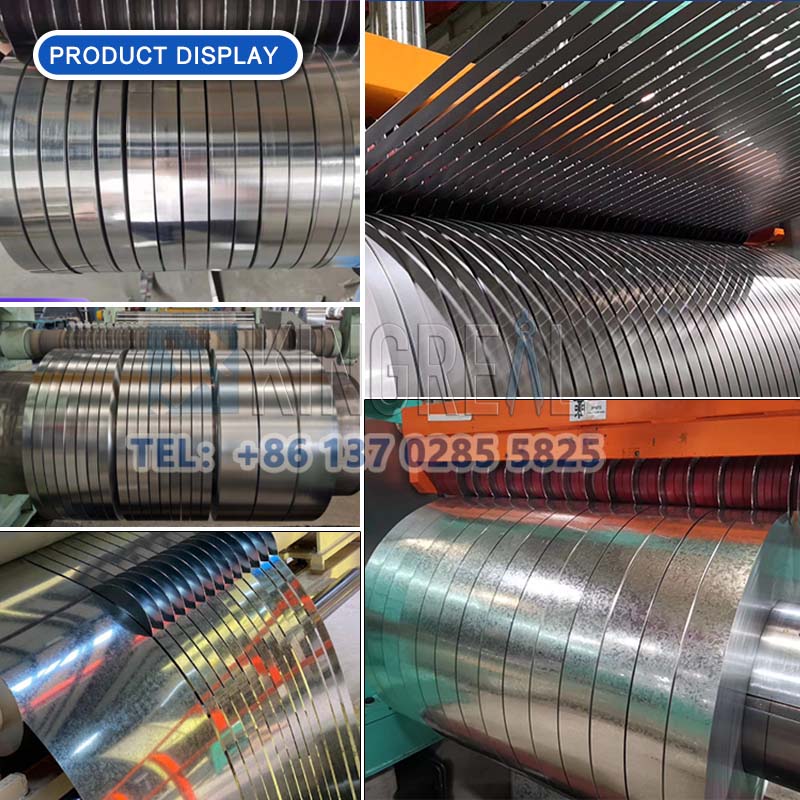

Coil slitting machine is a device used to slit wide metal coils into multiple narrow coils. Its main function is to divide large coils of metal materials into small coils of different widths as required to meet the requirements of subsequent production processes. Coil slitting machines play an important role in the metal processing industry, especially in the fields of automobiles, home appliances, packaging, electronics, etc.

Working process of coil slitting machines:

Uncoiling: Fix the large coil of metal materials on the decoiler and feed it into the coil slitting machine after uncoiling.

Slitting: Cut the metal coil into multiple narrow strips through the slitting knife group. The slitting knife group usually consists of two rows of disc knives, and the blade spacing can be adjusted according to needs.

Tensioning: Control the tension of the material through the tensioning device to ensure the smooth operation of the material during the slitting process to avoid wrinkles or deviations.

Reeling: Reel the strips after slitting into small coils for easy transportation and subsequent use.

BRUTE STEEL SLITTER can provide customers with a complete set of solutions for metal slitting and shearing. Coil slitting machines and cut to length lines each have their own functions in the metal processing process, but through reasonable combination, the whole process from wide metal coils to finished plates can be realized to meet different production needs.

The following is the workflow for combined use:

① Raw material preparation

First, the wide metal coils (such as steel coils, stainless steel coils or aluminum coils) are cut into narrow coils of the required width by the coil slitting machine. This step is mainly to provide materials that meet the size requirements for the subsequent shearing process.

② Slitting processing

The coil slitting machine cuts the raw materials into multiple narrow coils according to production needs, and the width can be adjusted according to different product requirements. For example, prepare materials for the production of metal plates or parts of different specifications.

③ Shearing processing

The narrow metal coils after slitting are fed into the cut to length line and cut into plates of fixed length by the cut to length machine. The cut to length line can accurately cut according to the preset parameters to ensure that the length and width of the plate fully meet the design requirements.

④ Finished product processing

The sheared plates are stacked or sent directly to the next process, such as stamping, bending or welding, according to production requirements.

① BRUTE STEEL SLITTER has different types of coil slitting machines for different production needs of customers. For example, in order to facilitate customers to slitting metal coils of different thicknesses, BRUTE STEEL SLITTER has launched thin plate slitting machines, medium plate slitting machines and heavy gauge slitting machines according to the thickness of metal raw materials. Among them, the thin plate slitting machine can handle 0.2-3mm metal coils, the medium plate slitting machine can handle 3-6mm metal coils, and the heavy gauge slitting machine can handle 6-16mm metal coils. In addition, BRUTE STEEL SLITTER has also designed two types customized coil slitting machines-belt bridle tension unit and dual-slitter head .

|

|

| Dual-slitter head coil slitting line | Coil slitting line with belt bridle tension unit |

② BRUTE STEEL SLITTER has cut to length lines with different shearing types. They are flying shear, swing shear and fixed shear. Customers can choose according to different needs for metal processing and work efficiency requirements. Among the many cut to length lines, BRUTE STEEL SLITTER's three-in-one cut to length line is the most popular among customers. This machine integrates unwinding, leveling and feeding. The servo system controls the movement of the feeding device to achieve accurate positioning of the plate and continuous feeding into the shearing area, thereby realizing continuous cutting and blanking production and processing of the plate. This greatly improves production efficiency and reduces the waiting time for manual operation.

③BRUTE STEEL SLITTER is good at making customized machines for customers. As long as you have a need, please give the drawing to BRUTE STEEL SLITTER. Engineers will definitely customize a coil slitting & cutting line for you.