Welcome to the BRUTE SLITTER “Other Coil Process Line Section”, where you will find a wide range of different types of metal coil processing equipment, processing processes including hydraulic decoiler, metal straightener machine, servo feeder, stamping, winding, etc., which are able to meet the different production needs of our customers.

Metal coil processing equipment is machinery and equipment designed to handle and process metal coils. Metal coils usually include steel, aluminum, copper and other metal materials that are stored and transported in rolls. Metal coil processing equipment can process these materials in a variety of ways to meet different industrial needs. Common types of metal coil processing equipment include the following:

1/Decoiler:

Decoiler is a kind of special industrial equipment used for sheet metal processing and material handling, which drives the coil to rotate and unfold by clamping the inner hole of the coil through the expansion and contraction reel, and realizes the continuous material conveying with the leveling machine and other equipment. It is mainly used for supporting, unfolding and leveling metal coils of different raw materials and sizes, providing continuous and stable material supply for the subsequent processes of metal processing production line.

Decoiler realizes the efficient handling and precise control of coil materials, and becomes the core equipment to improve the automation level and production efficiency in modern industry.

2/Metal Sheet Leveler

Metal sheet leveling machine is a kind of industrial equipment that eliminates the internal stress of metal plates and corrects surface defects through mechanical force, and its core function is to restore the bent, warped or wavy deformed metal materials to a flat state. Metal straightener machine is coil processing equipment and all kinds of metal secondary processing in the indispensable equipment, to solve the problem of stress deformation in metal processing, its technological evolution is towards high precision, intelligent and green manufacturing direction to deepen the development.

Generally speaking, metal sheet leveling machine can be used in all kinds of coil processing production lines, such as steel coil slitting machine, metal cut to length line and sheet metal perforated making machine production line to realize the role of leveling coil to improve the quality of the product processing, and at the same time can also be used as a separate leveling equipment. At the same time, it can be used as a separate leveling machine for leveling all kinds of metal raw materials, such as metal sheets, perforated metal sheets and perforated mesh.

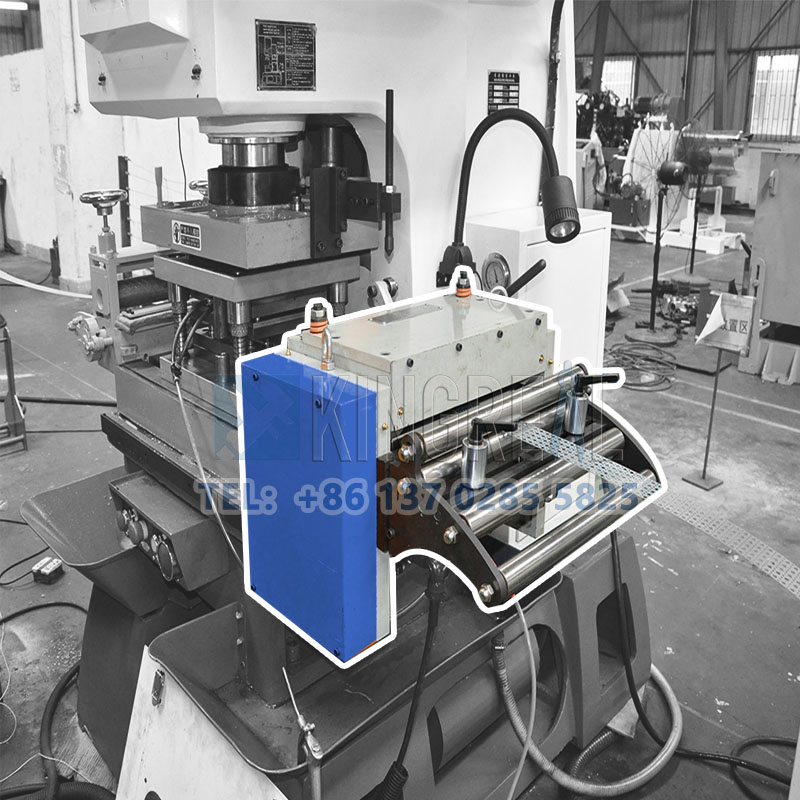

3/Servo feeder

Feeding equipment is the core device for automated material transportation in industrial production, which realizes accurate positioning and continuous transmission of raw materials, semi-finished products or finished products through mechanical force, pneumatic or electric drive. The core function of feeding equipment is to improve production efficiency and reduce manual intervention, and is widely used in metal processing, electronics manufacturing, food packaging and other fields.

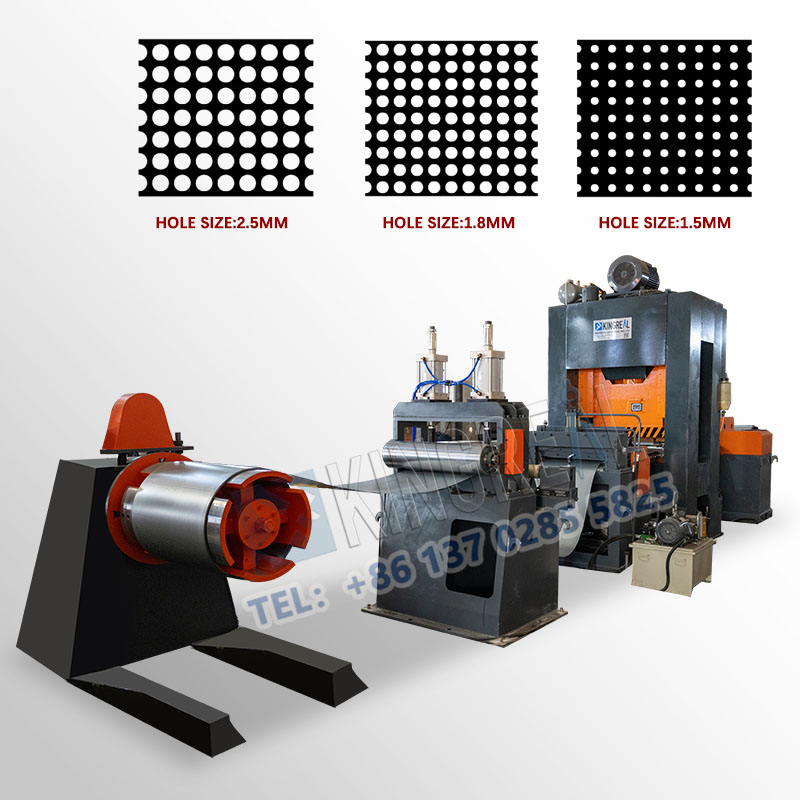

4/ Metal Sheet Perforation Machine

Unlike the uncoiler, leveler and feeder which are independent components to help realize the coil processing process, the metal perforation machine as a metal coil processing line has a complete coil processing capability, which is used to perforate different raw material coils into perforated sheets or perforated coils with different hole shapes and pitches, for secondary processing and production.

As a manufacturer of sheet metal perforation machines, BRUTE STEEL SLITTER has the customized design capability and extensive project experience to design sheet metal perforation line solutions according to the customer's perforated coil processing needs and market positioning.

BRUTE has a professional level of technology and production capacity in coil processing and manufacturing equipment, which can be customized according to the customer's production needs. Customers are welcome to send their production requirements or product images to BRUTE, which will provide customized solutions:

1. The ambient temperature and humidity in which the equipment operates can affect the working condition of mechanical components and the long-term stability of the equipment. Dust and contaminants in the environment may adversely affect the accuracy and life of the equipment.

2. Regular maintenance and servicing of the equipment can identify and solve potential problems in time to avoid equipment failure. Follow the correct operating procedures to minimize the damage to the equipment caused by human factors.

3. The training and experience of the operator affects the quality of operation and the level of maintenance of the equipment. Skilled operating skills can improve the operating efficiency of the equipment and reduce the incidence of failure.

4. Stable power supply is vital to the normal operation of the equipment. Supply chain stability and quality of components also affect the overall performance of the equipment.

- Coil Material

- Coil Thickness

- Coil Width

- Coil Weight

- Usage

BRUTE is a professional manufacturer in the field of stamping machinery and equipment in China, and can provide thick plate decoiler and straightener machine.This machine reduces material loops between decoiler and leveler processes, saving production space

BRUTE can provide the combine decoiler and straightener machine, which can reduces the material loop between the uncoiling and leveling process. As a professional machinery manufacturer in China, BRUTE is committed to providing customers with more design and innovative feeding machines.

BRUTE MACHINERY is one of the most professional metal sheets forming machines supplier in China. we can provide whole auto feeder machine solution, such as combined decoiler straightener and feeder machine. This machine is specially designed for high-strength steel to increase the efficiency of the production line

BRUTE 6 Roller Sheet Metal Leveler Machine are able to level the effect of different thicknesses of different raw materials and have become an integral part of the process. Click on us to find out more!