BRUTE SLITTER Precision Cut To Length Line, also called cut to length machine, used to decoiler, straightener, cut to length, and stack metal coils into flat sheets of the required length. Suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel, and various metal materials with coated surfaces for cutting to length and cross-cutting operations.

BRUTE SLITTER Precision Cut To Length Line

|

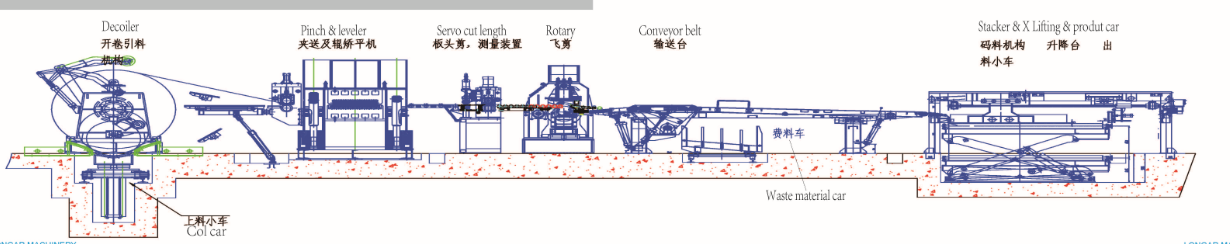

The Precision Cut-to-Length Line primarily consists of a feeding cart, uncoiler, leveling machine, feeding mechanism, shearing machine, conveying equipment, and stacking equipment. The cut-to-length machine can be equipped with a slitting machine to cut the sheet material into the required width, perform length-specific shearing, and stack the material. The High Precision Cut-to-Length Machine is a high-performance product integrating machinery, electricity, and hydraulics. It features high automation, simple and reliable operation, high length accuracy, excellent sheet flatness, and neat stacking.

Cut To Length Machine Classification

1. Based on the thickness of the sheet metal that can be cut to length, steel cut to length lines are divided into Light Gauge Cut To Length Lines (processing thickness 0.2–3.0 mm) and Heavy Gauge Cut To Length Machine (processing thickness 6–25 mm).

2. Based on the type of metal raw material being slit, cut to length line can be divided into copper cut to length machine, stainless steel cut to length lines, cold-rolled sheet cut to length lines, silicon steel cut to length, and tinplate cut to length equipment.

3.By degree of automation, they are classified into fully automatic cut to length line and semi-automatic cut to length machine.

|

|

Component Of Precision Cut To Length Machine

The precision cut-to-length machine primarily consists of a loading trolley, uncoiler, leveling machine, feeding mechanism, shearing machine, conveying device, and stacking device. The production line can be equipped with a slitting machine to cut the sheet material into the required width, perform length-specific cutting, and stack the material. The cut-to-length line is a high-performance product integrating machinery, electricity, and hydraulics. It features high automation, simple and reliable operation, high length accuracy, excellent sheet material flatness, and neat stacking.

Characteristics For Precision Cut To Length Line

“The parameters of the cut to length line are designed and manufactured by BRUTE SLITTER according to customer production requirements, supporting highly customized coil cut to length machine solution designs.”

|

|

Light Gauge Cut To Length Line |

Medium Gauge Cut To Length Machine |

Heavy Gauge Cut To Length Line |

|

Cutting system |

Mechanical Stop/Start, rotary or flying shear |

Mechanical, rotary and flying shear |

Hydraulic and flying shear |

|

Max. Thickness |

6mm | 8mm | 25mm |

|

Max. Width |

1800mm | 2000mm | 2600mm |

|

Max. Weight |

20T | 40T | 50T |

|

Max. Speed |

20-80M/Min |

20-80M/Min |

20-80M/Min |

|

1/The Cut To Length Machine utilizes a hydraulic or servo drive system, combined with a high-rigidity C-type frame structure, to perform cutting operations with precision within the 0.01mm range.

2/The Cut To Length Machine's dual servo feeding system, combined with a rotary encoder, achieves feeding accuracy of ±0.05mm. A hydraulic buffer device reduces cutting vibrations, ensuring a smooth, mirror-like surface finish.

3/The Cut To Length Machine uses a six-roll leveling machine to ensure the sheet material is flat and free of defects. 3/The Cut To Length Machine is equipped with a scrap cutting device that neatly separates edge materials.

4/Cut to Length Machine: The automatic stacking system neatly arranges finished products according to pre-set patterns. |

|

1/ How To Choose The Stack Device For Cut To Length Machine?

The auto stacking system for the cut-to-length line is available in two structural configurations: gantry-type stacking and open-type stacking.

The gantry-type structure features roller conveyors and a beating device, enabling steel plates conveyed by roller conveyors or conveyor belts to be neatly stacked onto conveyor flatbeds or hydraulic lift trucks. It is equipped with a pneumatic blowing system to effectively prevent plate scratching.

The open-type structure, equipped with left and right material guides and a pneumatic beating device, can stack steel plates conveyed by the conveyor rollers or conveyor belt onto the hydraulic lifting platform.

2/How To Turn On The Precision Cut To Length Line?

a. Before starting the cut-to-length line, you must check that the machine tool handles and moving parts are working properly.

b. Metal coils must be properly clamped and secured, and you must check that the leveling and straightening equipment is turned on at the same time.

c. After loading the material, you must check the center positioning and make sure the hole spacing is correct.

d. You must stop the machine to change speeds. When the cut-to-length machine is running, you must not touch the material with your hands, and you must not touch the mold or motor with your hands.

e. Do not place tools, measuring instruments, gloves, or other items on the machine tool rails or molds.

f. Do not leave the machine tool after startup; operate with full concentration.

3/What Is Application Of Precision Cut To Length Line?

In the automotive manufacturing industry, cut-to-length lines can cut high-strength steel plates into car body frames; in the new energy industry, cut-to-length machines can be used to precisely cut silicon steel sheets for motor cores.

Precision cut-to-length machines are industrial equipment that combine mechanical precision, electrical intelligence, and hydraulic stability, and have become a benchmark for metal forming processes in the era of intelligent manufacturing.

|

|

|

|