In the metal processing industry, cutting metal materials is essential. The commonly used shearing equipment is the cut to length line machine. Its working principle is that one blade moves back and forth relative to another blade. When cutting metal materials, the size of the metal cut to length line used varies depending on the size of the metal material to be cut, so various types of cut to length line machines have emerged in the market.

The working principle of the metal cut to length line is to apply pressure to the metal sheet through the cutting device and use the shear blade to cut the material into the required shape and size. Its main working process includes automatic feeding, precise cutting, automatic unloading and other steps, and it can automatically adjust the cutting speed and pressure as needed to ensure cutting accuracy and efficiency.

Metal cut to length lines play an important role in modern manufacturing, especially in metal processing, construction, automobile manufacturing, home appliances and other industries. Following are the importance of metal cut to length line in the market:

1. Improve production efficiency

The metal cut to length line has a high degree of automation, which can cut metal sheets quickly and accurately, significantly improving production efficiency. Traditional manual cutting is often inefficient and prone to errors, while metal cut to length lines are able to carry out continuous batch production, greatly improving processing speeds to meet the needs of modern large-scale production.

2. Ensure product quality

Cut to length line machines are capable of high-precision cutting, ensuring smooth, clean cut edges that meet tight tolerance requirements. The precise cutting process effectively reduces processing errors and improves product quality and appearance, especially in industries with high requirements on the size and shape of metal sheets (such as construction, home appliances, automobile manufacturing, etc.), ensuring smooth subsequent processing. conduct.

3. Reduce production costs

Through automation and precision cutting, the cut to length line machine reduces labor costs and raw material waste. Efficient cutting process can maximize the use of raw materials and reduce scrap rate. At the same time, efficient operation of equipment also reduces machine failures and downtime, thereby reducing overall production costs.

4. Improve processing accuracy

The cut to length line machine can accurately control the cutting size and edge quality of the plate through precision control systems and cutting devices. For metal products that require high precision and high quality, the shearing line can effectively avoid the instability in manual operation, reduce errors, and ensure high precision in the production process.

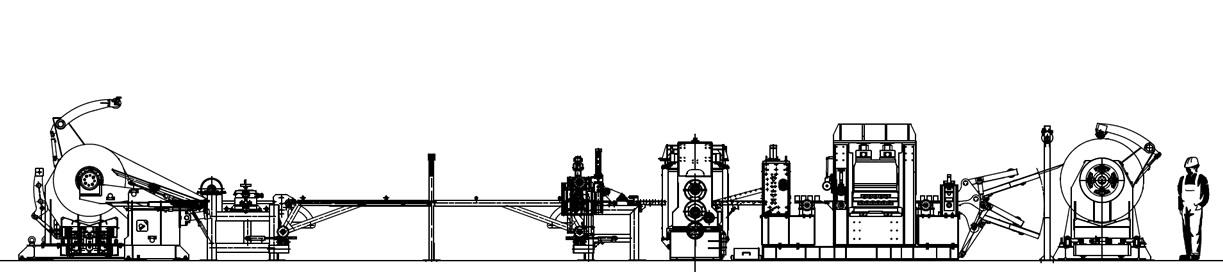

|

|

1. Feeding system: including feeding rollers, transmission devices and pressing devices, responsible for smoothly feeding metal sheets into the shearing area.

2. cut to length machine: It is the core component of the metal cut to length line, including shear blades and hydraulic system, used to cut metal sheets into required sizes.

3. Hydraulic system: provides the power required for shearing, controls the pressure and stroke of the blade, and ensures cutting accuracy.

4. Automatic control system: Equipped with CNC device, the operator can set parameters such as cutting length, speed and pressure through the touch screen to achieve automatic control.

5. Unloading system: Automatically unload the cut metal sheets and transport them to the downstream process or warehouse.

1. Material delivery: First, the metal sheet is transported to the shearing area through the feeding system. The feeding system ensures smooth material entry and positioning.

2. Automatic positioning: Through the CNC system, the metal cut to length line automatically measures and determines the required cutting size.

3. Shearing: The hydraulically driven metal cut to length line accurately cuts the metal sheets into preset sizes. At this point, the shear blades work under hydraulic pressure to ensure a smooth and neat cutting edge.

4. Automatic unloading: The sheared metal sheets are automatically discharged through the unloading system and enter the downstream links, such as packaging or further processing.

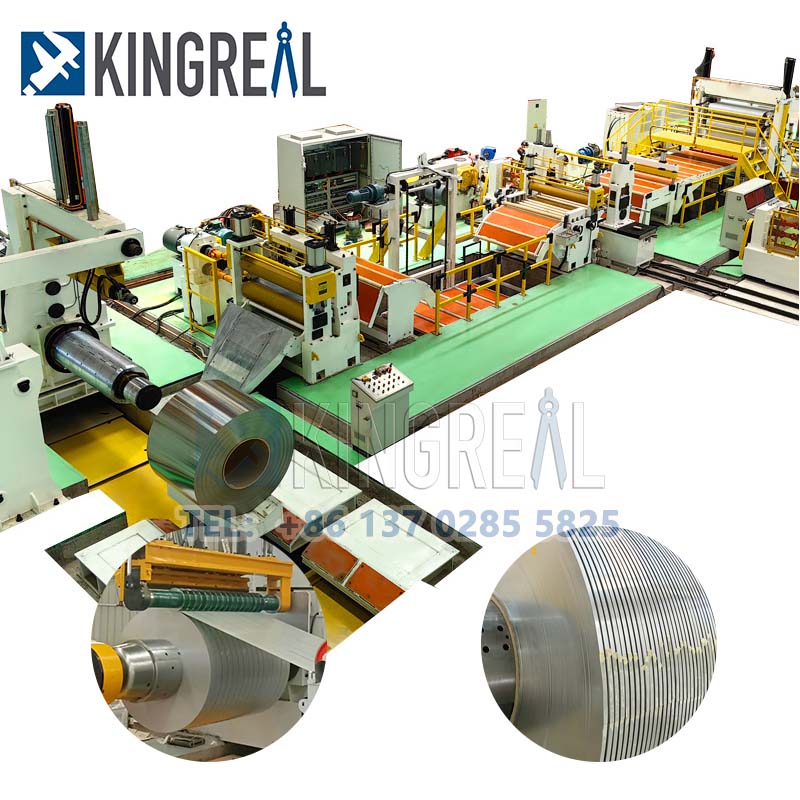

BRUTE STEEL SLITTER is a professional cut to length line machine manufacturer with more than 20 years of experience. It is a comprehensive company integrating R&D, production and sales. BRUTE STEEL SLITTER engineers are good at making customized cut to length line machine solutions according to the actual needs of customers, so BRUTE STEEL SLITTER does not provide the same machine to different customers. This also ensures that customers can fully adapt their production when using BRUTE STEEL SLITTER cut to length line machine.

-According to the thickness of metal raw materials, BRUTE STEEL SLITTER has launched light gauge cut to length line machine, medium gauge cut to length line machine and heavy gauge cut to length line machine.

|

|

|

-According to different shearing methods, BRUTE STEEL SLITTER has launched stop shearing cut to length line, fly shearing cut to length line and rotary shearing cut to length line.

|

|

|

-In order to cater to customers with small factory space, BRUTE STEEL SLITTER launched a three-in-one cut to length line.

If you have more special production requirements, customers are welcome to give drawings to BRUTE STEEL SLITTER. Engineers will provide perfect shear line solutions after sufficient communication.

|

|