Last week, BRUTE STEEL SLITTER engineers had an in-depth discussion with a customer from Kazakhstan about the customized metal cut to length equipment solution in the conference room.

|

|

|

This customer is an old customer of BRUTE STEEL SLITTER and has previously ordered coil slitting machine and metal punching machine. Due to the expansion of production needs, the customer chose BRUTE STEEL SLITTER again to seek professional cut to length line solutions.

1. Introduction to cut to length line components

At the beginning of the meeting, BRUTE STEEL SLITTER engineers gave a detailed explanation of the key components of the cut to length line, including:

- Decoiler: responsible for unrolling the metal coil to prepare for subsequent processing.

- Leveler: ensure the flatness of the metal sheet and improve the processing accuracy.

- Cutting station: the core part, completes the efficient cutting of the metal sheet.

- Waste collection device: automatically collects the waste generated during the cutting process to keep the working area clean.

- Conveyor belt: transports the processed metal sheets to the next process.

- Stacking table: neatly stack the cut metal sheets for subsequent processing.

In addition, BRUTE STEEL SLITTER also showed customers the strict selection process of raw materials in the component manufacturing process to ensure the durability and stability of the equipment.

2. In-depth exploration of customer needs

In order to design the most suitable cut to length line solution for customers, BRUTE STEEL SLITTER engineers communicated with customers in detail, mainly including:

- Metal coil thickness: understand the thickness range of metals that customers need to process.

- Metal coil material: confirm the type of material, such as steel, stainless steel or other special alloys.

- Production scale: clarify the customer's production needs to design an efficient production plan.

- Working hours: understand the customer's daily production time to ensure that the equipment can operate stably for a long time.

3. Share past successful cases

During the communication process, BRUTE STEEL SLITTER showed several successful cases, covering cooperation experiences with customers in India, Russia, Egypt, Turkey, Bangladesh and other countries. These cases not only enhanced the confidence of customers, but also provided them with a variety of reference metal cut to length equipment solutions.

Four metal cut to length equipment solutions that attracted customers' interest

After discussion, the following four cut to length line solutions particularly attracted the attention of Kazakhstan customers:

● Heavy Gauge cut to length line

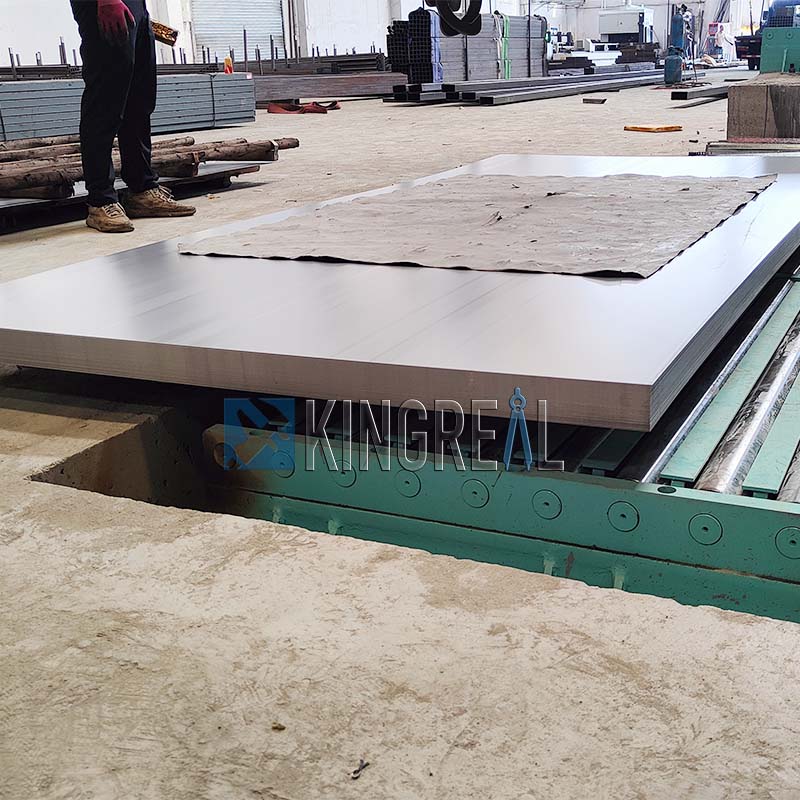

Traditional cut to length lines can usually only process metal coils with a thickness of 0.3-3mm, while Kazakhstan customers want to process thicker metal sheets. To meet this demand, BRUTE STEEL SLITTER engineers designed a heavy gauge cut to length line that can process metal coils with a thickness of up to 20mm.

|

|

|

- Features: Powerful cutting ability and efficient processing performance to meet the processing needs of thick plates.

- Advantages: Expand customer product lines and improve market competitiveness.

● Metal cut to length equipment with Dual stacker

In order to improve production efficiency and achieve high automation, BRUTE STEEL SLITTER has developed a double stacker design.

|

|

|

- Function: After the metal sheets are processed, they will be automatically transported to the double stacking table for stacking.

- Advantages:

- Higher speed: The double stacking table can process two groups of plates at the same time, greatly improving production efficiency.

- High degree of automation: reduce manual intervention and reduce labor costs.

● Cut to length line with Laminating device

During the shearing process of metal sheets, surface scratches are the focus of customers' attention. BRUTE STEEL SLITTER is specially equipped with a laminating device for the cut to length line:

|

|

|

- Working principle: Before the metal sheet enters the cut to length line, the laminating device will automatically cover it with a layer of protective film to avoid scratches during the cutting process.

- Advantages:

- Surface protection: Ensure that the surface of the metal sheet is clean and undamaged.

- Convenient subsequent processing: Provide high-quality raw materials for customers' subsequent processing operations.

● Cut to length line with Double leveling machine

In order to meet customers' high requirements for the flatness of metal sheets, BRUTE STEEL SLITTER designed a double leveling machine configuration for the cut to length line:

|

|

|

- Workflow: The metal sheet first undergoes preliminary leveling by the first leveling machine, and then enters the second leveling machine for secondary leveling.

- Advantages:

- High flatness: The two leveling processes effectively eliminate the bending and unevenness of the metal sheet.

- Higher quality: The leveling effect is significantly improved to meet high-standard production needs.

Through sufficient communication and looking at past successful cases of BRUTE STEEL SLITTER, the Kazakhstan customer and BRUTE STEEL SLITTER engineers finally confirmed the manufacturing plan of the cut to length line:

-Coil Thickness: Up To 20MM

-Coil Width: 2000-2500MM

-Coil Material: HR Coil

BRUTE STEEL SLITTER provides customers with many customized metal cut to length equipments, including:

- High Speed Cut To Length Line

- Fly Shearing Cut-To Length Line

- Cut To Length Line With Trimming

- Steel Coil Cutting Machine For Narrow Strip

|

|

|

|