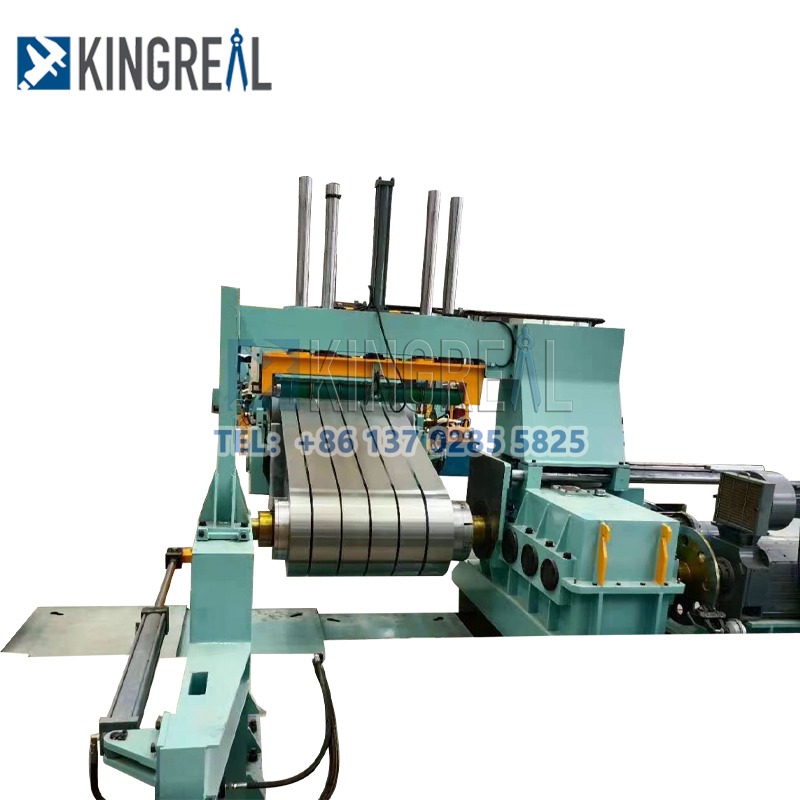

Coil slitting equipment is a common mechanical equipment, mainly used to cut large coils into required small coils. It is used in the fields of automobile manufacturing, aviation, construction, etc., which provides convenience for production and processing.

The working principle of the coil slitting machine is to cut the coil into the required width and length through the rotation of the knife wheel. The rotation speed of the knife wheel and the pressure of the blade can be adjusted according to different materials and requirements. At the same time, the coil slitting equipment is also equipped with automatic counting and automatic shutdown functions to ensure the accuracy of cutting.

|

|

Market demand is another important factor in promoting the application prospects of coil slitting machines in the metal processing industry. With the continuous development of the metal processing industry at home and abroad, the demand for metal sheet cutting and slitting is also increasing. The application of coil slitting equipment can improve production efficiency, reduce manual operation, reduce labor intensity and production costs, and the quality of cutting and slitting is more stable. Especially in the automotive, home appliances, construction, shipbuilding and other industries, the requirements for cutting and slitting of metal sheets are getting higher and higher. Therefore, the market demand for coil slitting equipment in the metal processing industry will continue to increase.

|

|

The development trend is another key factor in the application prospects of coil slitting machines in the metal processing industry. With the deepening of economic globalization, the pursuit of higher benefits and lower costs in the metal processing industry has become a general development trend. The application of coil slitting equipment just meets this demand. It can greatly improve production efficiency, reduce production costs, improve product quality, and enhance market competitiveness. At the same time, with the continuous improvement of environmental awareness, coil slitting machines also have advantages in reducing waste and pollution, which helps to achieve sustainable development. Therefore, the application prospects of slitting machines in the metal processing industry are very broad.

Decoiler: This is the part of the machine that fixes the roll of material to be slitting.

Guide system: This system helps guide the material when unwinding, ensuring that it remains straight and centered when slitting.

Cutting system: This is the part of the machine that actually cuts the material. The cutting system can be composed of a variety of different types of blades or knives, depending on the type of material being cut and the required incision width.

Rewinder: This is the part of the machine that rolls the cut material into smaller rolls.

Control panel: This is the part of the machine that allows the operator to control the speed of unwinding and rewinding, as well as the width of the slit.

Safety guards: These are used to protect the operator from the moving parts of the machine.

The following is the basic slitting process of the coil slitting equipment:

Feeding preparation

- Loading: First, load the wide metal coil (usually steel plate, aluminum plate, stainless steel plate, etc.) onto the loading device of the slitting machine. The coil maintains the appropriate tensile force through a tension control system to prevent the metal plate from deforming.

- Leveling: Some coil slitting machines are equipped with leveling devices to remove the corrugations of the metal sheet and make the sheet flat, which helps the subsequent cutting quality.

Slitting process

- Guiding: The metal sheet passes through guide rollers or guide devices to ensure that the metal sheet enters the cutting area along the correct path.

- Cutting: After entering the cutting area, the blades of the slitting machine start working. Coil slitting machines usually have multiple rotating blades, which cut the metal sheet along the set spacing. There are two common types of blades:

- Rotary blades: The blades usually rotate horizontally or vertically, suitable for fast slitting.

- Intermittent blades: The blades cut intermittently while feeding.

- Cutting accuracy: The spacing of each blade can be adjusted to ensure that the cut metal strips meet the required width.

Reeling after slitting

- Reeling: After cutting, the metal strips are guided to the reeling system. The reeling system usually includes multiple reels to neatly wind the slit metal strips into coils for subsequent processing or transportation.

- Adjustment: The metal strip after slitting usually needs to be properly tensioned through a tension control system to ensure a smooth winding process and avoid waste or sheet deformation.

Control system

- Automatic control: Modern metal slitting machines are usually equipped with a computer numerical control system (CNC), which can accurately set parameters such as cutting width, speed, blade spacing, and monitor the slitting process in real time.

- Safety system: In order to ensure safe operation, coil slitting machines are generally equipped with emergency stop devices, automatic alarm systems, etc.