The metal cut to length machine is a highly efficient metal processing equipment, which is divided into: stop shearing, high-speed shearing, and flying shearing according to its speed.

It is widely used in many industries such as automobile manufacturing, home appliance production, building materials, aerospace, etc. The equipment can accurately shear metal coils according to the set size requirements, and is suitable for the processing of various metal materials such as steel, stainless steel, aluminum, and copper.

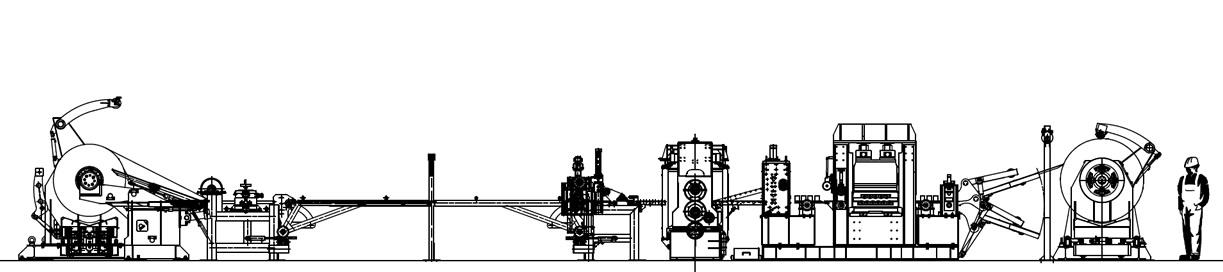

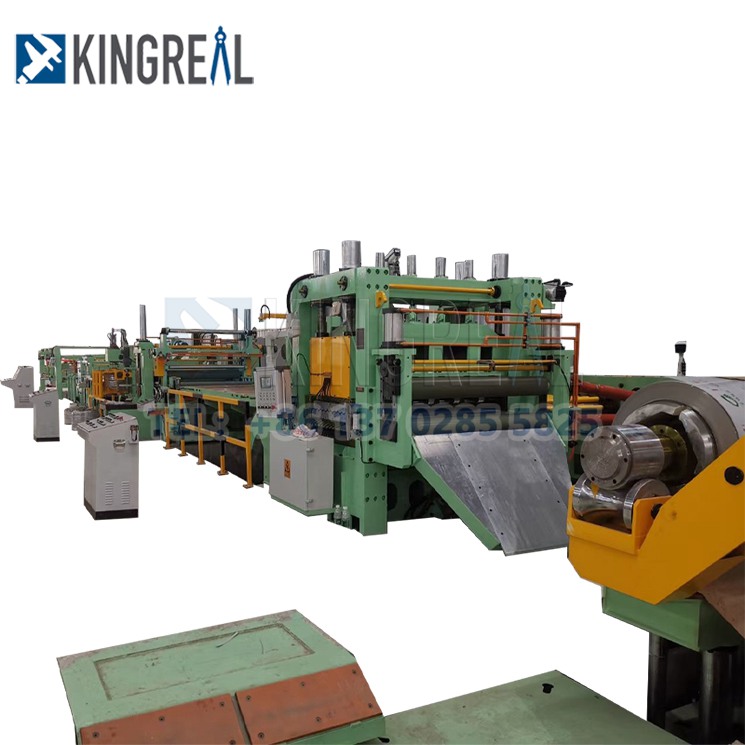

BRUTE STEEL SLITTER cut to length line has advanced design and superior performance, which can meet the diverse production needs of customers. The entire metal cut to length machine consists of several key parts, including decoiler, straightening machine, feeding device, metal cut to length machine, and stacking system.

The decoiler is responsible for unwinding the metal coil and conveying it to the production line; the straightening machine flattens the material to ensure that its surface is smooth and flat; the feeding device can accurately control the feeding speed and position of the metal sheet; the metal cut to length machine accurately shears the material according to the preset size, and finally the stacking system completes the neat stacking of the finished product.

(1) Choose high-performance equipment

Configuring advanced cut to length line equipment is the basis for improving efficiency. High-quality metal cut to length machines usually have higher production speeds, more precise shearing accuracy and more stable operating performance. For example, choosing a shearing device equipped with a servo motor feeding system and high-precision tools can significantly reduce errors and increase shearing speed.

(2) Modular design

The metal cut to length machine adopts modular design and can quickly adjust its configuration according to production needs, such as replacing different types of cutting tools, adding or reducing feeding devices, etc. This flexibility helps to adapt to diverse production needs, reduce equipment adjustment time and improve production efficiency.

(3) Automation and intelligence

The automated cut to length line is equipped with an intelligent control system (such as PLC or HMI), which can realize functions such as automatic feeding, length measurement, shearing and stacking. Intelligent operation not only reduces manual intervention, but also optimizes production processes through data analysis and further improves efficiency.

(1) Standardization of operating procedures

Develop standardized operating procedures to ensure that each link is carried out in accordance with best practices. Operators need to be familiar with equipment performance and master correct operating methods to avoid efficiency losses due to operating errors.

(2) Optimize production scheduling

Reasonably arrange the operation time of the cut to length line according to the production plan to avoid long-term idleness or overuse of the equipment. At the same time, by optimizing production batches and switching time, efficiency losses caused by frequent adjustments can be reduced.

(3) Strengthen staff training

Highly qualified operators are an important guarantee for improving the efficiency of the metal cut to length machine. Enterprises should organize training regularly to enable employees to master equipment operation skills and emergency handling capabilities to ensure a smooth production process.

(1) Introducing advanced technology

Using the latest CNC technology and intelligent sensors, the operating status of the metal cut to length machine can be monitored in real time, and abnormal situations can be warned or automatically adjusted. For example, real-time monitoring of feeding speed and shearing accuracy can effectively avoid material waste and quality problems.

(2) Optimize the shearing process

Optimize shearing parameters (such as tool angle, pressure and speed) according to the needs of different materials and thicknesses. Through experiments and data analysis, BRUTE STEEL SLITTER finds the optimal shearing process parameters to improve efficiency while ensuring quality.

(3) Develop special functions

In response to the needs of specific industries, BRUTE STEEL SLITTER develops metal cut to length machines with special functions, such as multi-functional equipment equipped with punching, bending or coating functions, to reduce subsequent processes and improve overall production efficiency.

|

|

(1) Regular maintenance

The efficient operation of the cut to length line is inseparable from good maintenance. Enterprises should develop detailed maintenance plans, regularly check key components of equipment (such as tools, bearings, feeding devices, etc.), and replace worn parts in a timely manner to avoid downtime due to equipment failure.

(2) Lubrication and cleaning

Ensure the normal operation of the equipment's lubrication system and reduce friction loss of parts. At the same time, keep the equipment clean to prevent metal chips and dust from damaging the equipment.

(3) Establish spare parts inventory

Establish a spare parts inventory for commonly used parts to ensure quick replacement when equipment fails, reducing downtime.

(1) Production data monitoring

By installing a data acquisition system, the production data of the cut to length line can be recorded in real time, including operating time, output, failure rate, etc. Through data analysis, BRUTE STEEL SLITTER can identify the key factors affecting efficiency and develop targeted improvement measures.

(2) Introducing performance evaluation

Regularly evaluate the production efficiency of the cut to length line, combine the data analysis results, optimize the production process and equipment configuration, and ensure that the equipment is always in the best operating condition.