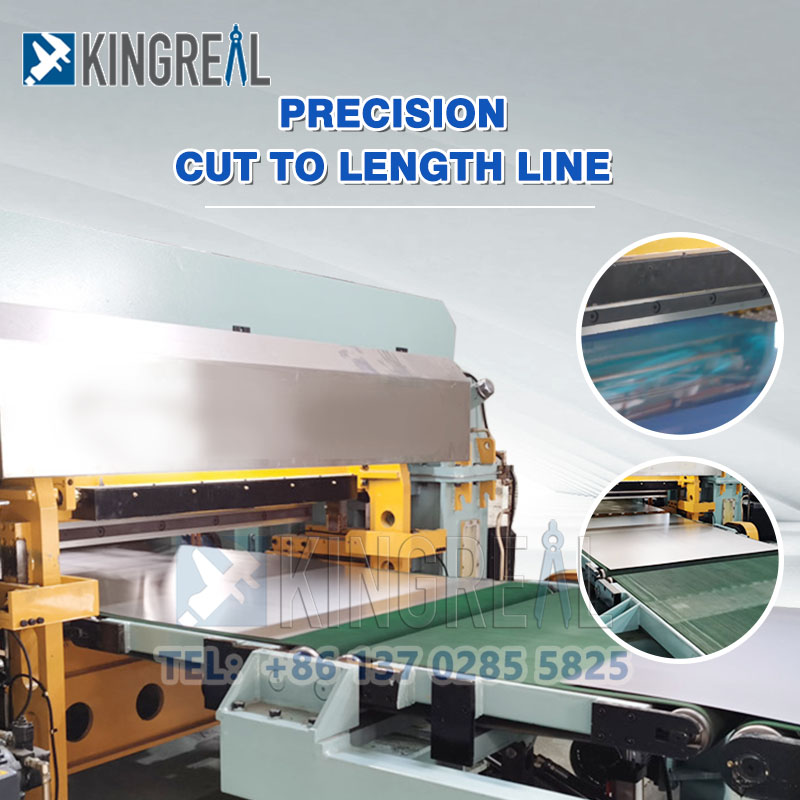

The ss ctl line is an indispensable part of the modern metal processing industry. It produces flat plates of the required length and stacks them by uncoiling, leveling, sizing and shearing metal coils. This process is applicable to a variety of metal materials, such as cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and surface-coated metal materials.

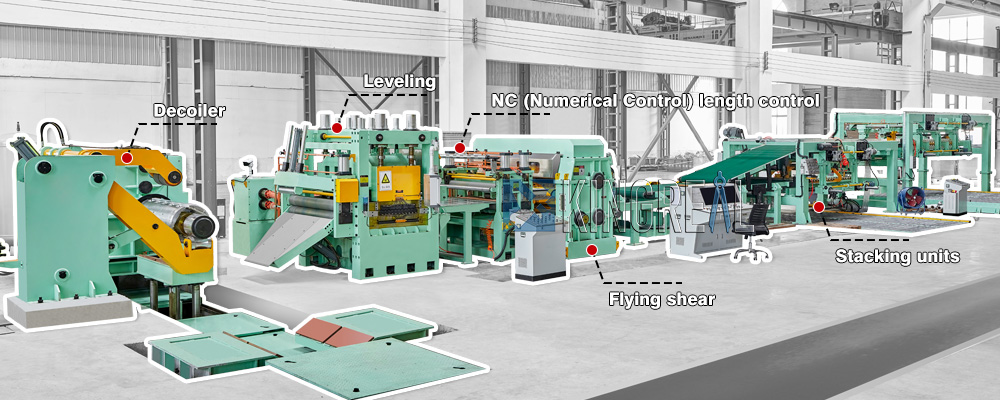

The design of the stainless steel cut to length equipment usually includes a loading trolley, an decoiler, a leveler, a feeding mechanism, a shearing machine, a conveying device and a stacking device, which can efficiently complete the cross-cutting operation of metal materials. In this article, BRUTE STEEL SLITTER will discuss the importance of the ss cut to length machine with you, and conduct an in-depth analysis from multiple aspects such as its application field, efficiency improvement, return on investment and customized services.

The workflow of the stainless steel cut to length equipment is relatively complex, and its main components perform their respective duties to ensure the smooth progress of the entire production process.

1. Loading trolley: Feed the metal coil into the production line

2. Decoiler: Unroll the coil and prepare for subsequent processing.

3. Leveler: Make the plate flat and eliminate internal stress through multiple bending and stretching.

4. Feeding mechanism: Feed the leveled plate into the shearing machine.

5. Shearing machine: Cut the plate into the required size according to the set length.

6. Conveying device: Convey the sheared plate to the stacking device.

7. Stacking device: Stack the finished plates neatly for subsequent processing and transportation.

The stainless steel cut to length equipment plays a vital role in the metal processing industry. It meets the needs of various industries for metal plates through efficient shearing operations. And it has a high degree of automation, simple and reliable operation. The importance of ss ctl line in the metal processing industry is mainly reflected in the following aspects:

2.1 Wide range of applications

The application range of stainless steel cut to length equipment covers almost all industries that require metal plates. Specifically, it includes but is not limited to the following areas:

- Construction industry: In construction, metal sheets are often used for structural support, exterior wall decoration, roofing materials, etc.

- Automobile manufacturing: Sheared metal sheets are used for key components such as body manufacturing and chassis structure.

- Home appliance industry: The outer shell and internal structure of home appliances such as refrigerators and washing machines require sheared metal materials.

- Machinery manufacturing: The production of shells, frames and parts of various mechanical equipment depends on the efficient processing of shearing lines.

- Shipbuilding: The manufacture of hull structures and their internal equipment requires a large number of metal sheets.

These industries have strict requirements on the specifications, quality and production efficiency of metal sheets, and ss cut to length machines just meet these requirements.

|

|

2.2 Improve production efficiency

The ss ctl line is composed of various precision components and can realize fully automated operation. Compared with manual operation, the efficiency of the stainless steel cut to length equipment is significantly improved. The machine can run continuously without being affected by fatigue, ensuring the continuity of production. Specifically, the advantages of automated equipment are reflected in:

- High-speed production: The ss cut to length machine can complete a large number of shearing tasks in a short time to meet the production needs of the enterprise.

- Stable quality: Automated operation reduces human errors and improves product consistency and quality stability.

- Reduced production cycle: Fast processing speed enables enterprises to shorten production cycles and respond to market demand more quickly.

2.3 High return on investment

Although the initial investment cost of the stainless steel cut to length equipment is relatively high, its return on investment is very considerable in the long run. Especially in developed countries, where labor costs are high, the advantages of using ss cut to length machines are more obvious. Specifically:

- High production capacity: ss ctl lines can produce a large number of qualified products in a short period of time, greatly improving production efficiency.

- Save labor costs: Although the cost of purchasing equipment is high, it can significantly reduce labor costs in long-term use.

- Long equipment life: Modern stainless steel cut to length equipment are well designed and can be used for many years if properly maintained, thereby spreading the investment cost.

With the changes in market demand, customized services for ss ctl lines have become increasingly important. Modern ss cut to length machines are usually customized according to customer drawings and actual production needs to ensure that they are highly matched with customer production processes.

3.1 Advantages of customization

- Meet specific needs: Customers can customize various parameters of the stainless steel cut to length equipment, such as shearing thickness, length, etc., according to their own production needs to ensure the efficiency of the equipment.

- Improve the convenience of operation: Customized design makes the operation more convenient and reduces the learning cost of operators.

- Enhance market competitiveness: Customized stainless steel cut to length equipment can help companies quickly adapt to market changes and improve the market competitiveness of products.

3.2 Customized solutions for BRUTE STEEL SLITTER

Take BRUTE STEEL SLITTER as an example. The company provides customers with customized ss ctl line solutions. The most popular products include:

- Light gauge ss cut to length machine: It can handle plates with a thickness of 0.3-3mm, suitable for thin plate materials with higher demand.

- Medium gauge ss cut to length machine: It can handle plates with a thickness of 0.3-6mm, and is widely used in the shearing of medium-thick metal materials.

- Heavy gauge ss cut to length machine: It can handle plates with a thickness of 6-20mm to meet the needs of heavy-duty industries.

This customized service not only improves the applicability of the stainless steel cut to length equipment, but also enables customers to better respond to market changes.