Silicone steel slitting machines are an indispensable and important equipment in modern manufacturing. Their main function is to slit large metal coils into narrow strips required by customers for subsequent processing. Silicone steel slitting lines are widely used in many industrial fields, especially in metal processing, automobile manufacturing, electronics and home appliance industries. In this article, BRUTE STEEL SLITTER will discuss with you and share some practical tips for maintaining silicone steel slitter.

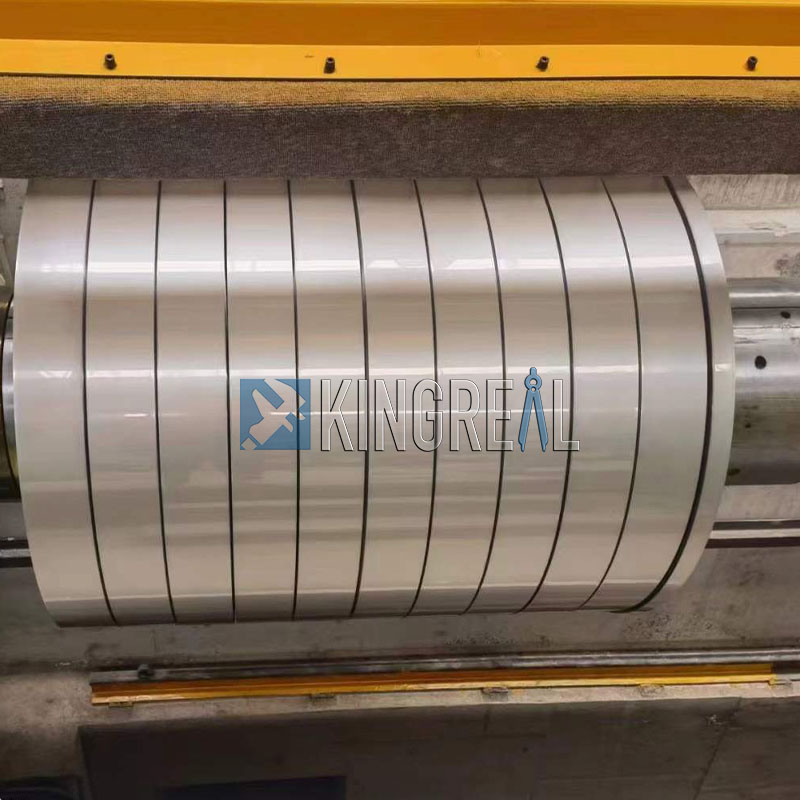

Silicone steel slitting lines are mechanical equipment specially used to slit wide metal coils into narrow strip products. Its working principle is relatively simple, but the technology involved is relatively complex. Silicone steel slitter usually consist of a feeding part, a cutting device, a winding part and a control system. During the working process, the metal coil is fed into the silicone steel slitting machine through the feeding part, and after precise cutting, it is finally rolled into multiple narrow strips to meet the needs of different customers.

The design of the silicone steel slitter should take into account both the cutting accuracy and the production efficiency and safety. With the development of science and technology, many modern silicone steel slitting lines have been equipped with advanced automation systems, which can achieve high-speed and high-efficiency production.

The demand for silicone steel slitter in the market is increasing, and many countries including the United States, the United Kingdom, Germany, India, Russia, etc. have aroused a craze for purchasing silicone steel slitting lines. The reasons are as follows:

1. Improve production efficiency

Automated silicone steel slitting machines have a fast working speed and can complete a large amount of slitting work in a short time. This greatly improves production efficiency and enables factories to meet customer order needs in a shorter time.

2. Reduce labor costs

Traditional slitting methods often require a lot of manual operation, which is not only inefficient but also prone to human errors. The automated silicone steel slitting line can reduce dependence on manual labor, thereby reducing labor costs. In addition, the stability and consistency of the machine also improve the quality of the product and reduce the defective rate caused by human factors.

3. Improve product quality

The silicone steel slitter can achieve high-precision cutting to ensure that the width and thickness of each metal material meet customer requirements. This high-quality cutting not only improves the market competitiveness of the product, but also enhances customer satisfaction.

4. Flexible production capacity

Silicone steel slitting machines usually have adjustable cutting width and speed, which can be flexibly adjusted according to customer needs. This flexibility enables factories to respond quickly to market changes and meet the personalized needs of different customers.

|

|

|

Due to the advantages and characteristics of the above-mentioned silicone steel slitting lines, it is of great significance for the factory to have a silicone steel slitting machine that can operate normally for a long time.

1. Guarantee the construction period

In the manufacturing industry, the control of the construction period is crucial. The normal operation of the silicone steel slitter can ensure the delivery of products on time and reduce the risk of construction delays. Any equipment failure may cause the production line to stagnate, thus affecting the entire production plan.

2. Guarantee efficiency

Efficient silicone steel slitting lines can produce continuously and stably to ensure the maximum production capacity of the factory. The efficient operation of the equipment means more output, less downtime, and lower production costs.

3. Guarantee the quality of slitting

The quality of the silicone steel slitter directly affects the quality of the final product. By maintaining and adjusting the silicone steel slitting line, the accuracy and consistency of the cutting can be ensured, thereby improving the qualified rate of the product. Good product quality can not only enhance the reputation of the company, but also help the company to be invincible in the fierce market competition.

|

|

|

Today, BRUTE STEEL SLITTER will share the maintenance tips of the silicone steel slitting line with you, hoping to help you:

1. Regular inspection

Regular comprehensive inspection of the silicone steel slitter is the basis for ensuring the normal operation of the equipment. The inspection content includes the wear of mechanical parts, the oil level and quality of lubricating oil, the connection and function of the electrical system, etc. Through regular inspection, potential problems can be discovered in time to avoid equipment failure.

2. Keep clean

The cleanliness of the silicone steel slitter directly affects its operating efficiency and service life. Clean the metal chips, oil and dust on the machine regularly to ensure that all parts of the equipment can work properly. Especially after the cutting operation, be sure to clean the working area to prevent metal chips from affecting subsequent operations.

3. Replace worn parts in time

During the use of the silicone steel slitting line, some parts such as knives and bearings will wear out due to long-term use. Check the status of these parts regularly and replace worn parts in time to ensure the cutting accuracy and running stability of the silicone steel slitting machine.

4. Regular lubrication

Lubrication is an important part of maintaining the silicone steel slitting line. Regularly filling moving parts with lubricating oil can reduce friction and extend the service life of the equipment. Make sure to use the right type of lubricating oil and lubricate according to the equipment manufacturer's recommendations.

|

|

|

5. Equipment training

Ensure that operators receive professional training and master the correct operating procedures and maintenance knowledge. The quality of operators directly affects the efficiency and safety of equipment use. Organize training and assessment regularly to improve the skill level of operators.

6. Monitor operating status

Install monitoring equipment to monitor the operating status of the silicone steel slitter in real time, and you can detect abnormal conditions of the equipment in time. Through data analysis, you can predict equipment failures, perform maintenance in advance, and avoid downtime losses.

7. Develop a maintenance plan

Develop a detailed equipment maintenance plan, including a schedule for regular inspection, maintenance, and replacement of parts. By implementing a maintenance plan, you can systematically manage the maintenance of the equipment and ensure that the silicone steel slitter is always in the best condition.