|

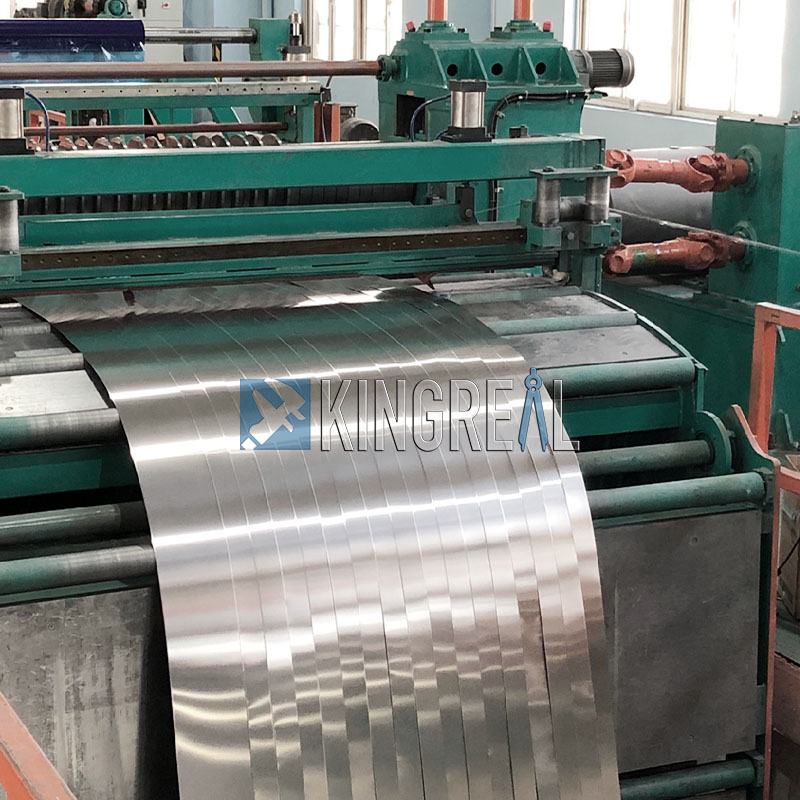

Aluminum coil slitter is a kind of equipment specially used to slit large aluminum coils into preset lengths. Its working principle is to accurately divide aluminum coils into narrow aluminum strips required by customers through a series of precision components, including decoiler, tension station, front loop, main coil slitter, waste collection device, back loop, recoiler and separator. This aluminum slitter machine plays an important role in the aluminum processing industry and is widely used in many fields such as automobiles, construction, electronics and home appliances. |

|

The growing demand for customized aluminum slitter is mainly driven by the following aspects:

1. Diversified market demand

With the acceleration of industrialization, the demand for aluminum materials in various industries is becoming more and more diversified. Different industries and products have different requirements for the width, thickness and surface treatment of aluminum strips. For example, the automotive industry requires thin and light aluminum, while the aerospace industry may require thicker aluminum to meet strength requirements.

2. Technological progress

Advances in modern manufacturing processes have enabled aluminum coil slitter to continuously improve their accuracy and efficiency, meeting higher production standards. Customized solutions can better adapt to these technological changes and help companies improve production efficiency and product quality.

3. Personalized production

In the context of Industry 4.0, personalized production has become a trend, and companies hope to respond quickly to market changes and produce products that meet specific needs. Customized aluminum slitter can help companies achieve this goal of flexible production.

4. Competitive pressure

In the face of fierce market competition, companies need to continuously optimize production processes to reduce costs and improve efficiency. Customized equipment can provide exclusive solutions to help companies remain invincible in the fierce market.

|

|

|

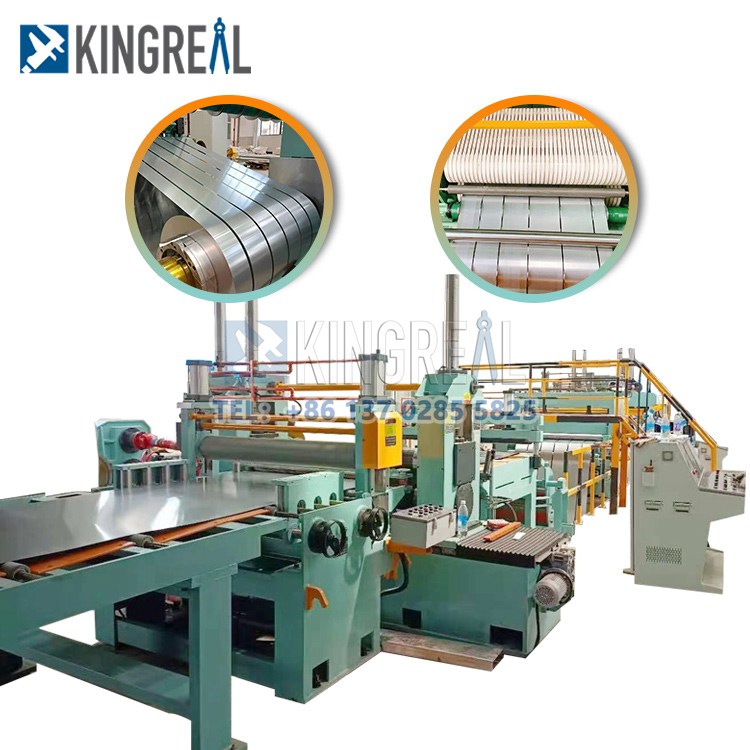

1. Fully meet customer needs

Customized aluminum slitter machines can fully meet the specific needs of customers. Regardless of the thickness of the coil, BRUTE STEEL SLITTER can provide the corresponding aluminum coil slitter. BRUTE STEEL SLITTER designs different types of aluminum slitter machines for customers, including:

- Light gauge aluminum coil slitter: suitable for slitting metal coils of 0.2-3mm to meet the processing needs of light aluminum.

- Medium gauge aluminum slitter machine: suitable for slitting metal coils of 3-6mm, suitable for processing aluminum with medium strength and thickness.

- Heavy gauge aluminum coil slitter: suitable for slitting metal coils of 6-16mm to meet the processing requirements of heavy aluminum.

This classification design enables aluminum coils of different thicknesses to be effectively processed, greatly improving the flexibility of production.

|

|

|

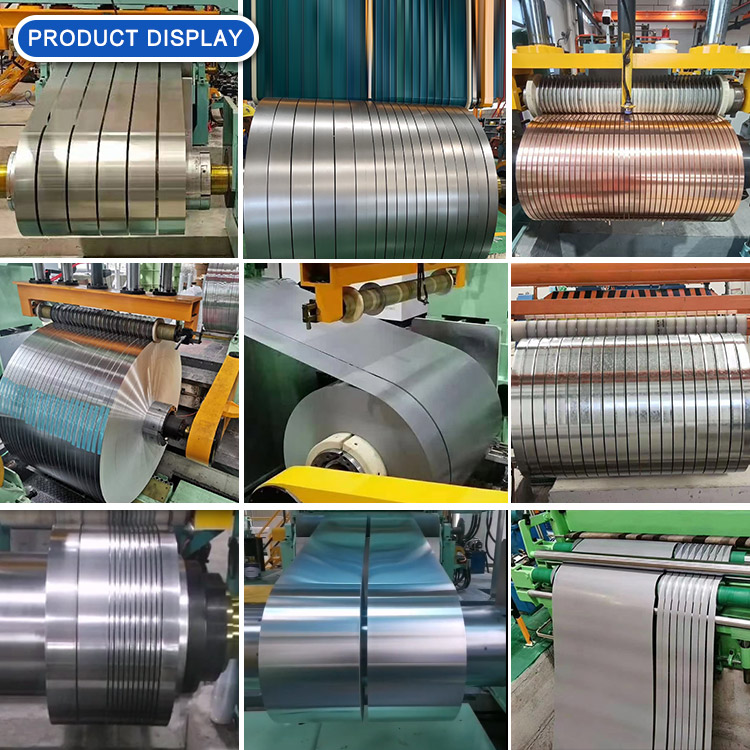

2. Design exclusive aluminum slitter machines according to customer needs

BRUTE STEEL SLITTER can design exclusive aluminum coil slitter according to the special needs of customers, including:

- Aluminum slitter machine with lamination: Before the metal coil is slitting, a layer of film is applied to the metal sheet through the laminating device. This design effectively ensures that the surface is not scratched during the slitting process, and also facilitates subsequent transportation and storage.

- Aluminum coil slitter with protective shield: In order to protect the production safety of workers, BRUTE STEEL SLITTER installed a protective shield for the aluminum slitter. This design not only improves the safety of operation, but also reduces the risk of worker injury.

- Narrow strip aluminum coil slitter: BRUTE STEEL SLITTER aluminum slitter machine supports slitting out narrow strips and can be customized according to the specific needs of customers (such as the size of the narrow strips). Through close communication with customers, BRUTE STEEL SLITTER engineers can design the most suitable aluminum coil slitter according to customers' drawings and actual production conditions.

|

|

|

3. Improve production efficiency

The customized aluminum slitter machine is designed with full consideration of production efficiency. Through optimized mechanical structure and intelligent control system, the aluminum coil slitter can complete the slitting task with higher speed and accuracy. Specifically:

- Quick tool change system: Customized models are usually equipped with a convenient tool change system, which can quickly replace tools of different specifications and reduce downtime.

- Automated control: The integrated advanced automated control system can monitor the production status in real time, automatically adjust the production parameters, and ensure that the aluminum slitter machine operates in the best condition.

- Efficient waste treatment: The aluminum coil slitter is equipped with an efficient waste collection device, which can clean up the waste generated during the production process in time to avoid affecting production efficiency.

4. Reduce production costs

Although the initial investment of customized aluminum slitter machines is relatively high, in the long run, it can significantly reduce production costs. Specific advantages include:

- Reduced waste of raw materials: Through precise slitting control, aluminum coils can be used to the maximum extent, reducing raw material costs.

- Reduced labor costs: Aluminum coil slitter with a high degree of automation can reduce dependence on labor, thereby reducing labor costs.

- Improved production efficiency: Higher production efficiency means that more products can be produced in the same amount of time, thereby diluting fixed costs.

5. Enhanced product competitiveness

In today's increasingly competitive market environment, having a customized aluminum slitter machine can help companies improve the quality and consistency of their products, thereby enhancing market competitiveness. Customized equipment can ensure that the aluminum strips produced meet the strict requirements of customers, improve customer satisfaction, and thus promote sales growth.

6. Flexible response to market changes

Customized aluminum coil slitter can be quickly adjusted according to changes in market demand. Whether it is the launch of new products or the improvement of production processes, customized aluminum slitter can respond quickly to help companies maintain their competitive advantage in the changes.

|

|

|

7. Provide comprehensive technical support

BRUTE STEEL SLITTER not only provides customized aluminum slitter machines, but also provides comprehensive technical support and services. Including aluminum slitter installation, commissioning, training and after-sales service, etc., to ensure that customers can use the equipment smoothly and maximize its production efficiency.

8. Enhance brand image

Using high-performance customized aluminum coil slitter can enhance the brand image of the company. When customers see the investment made by the company in production aluminum slitter machine, they often have a higher degree of trust in product quality. A good brand image helps companies gain a larger share in the market.